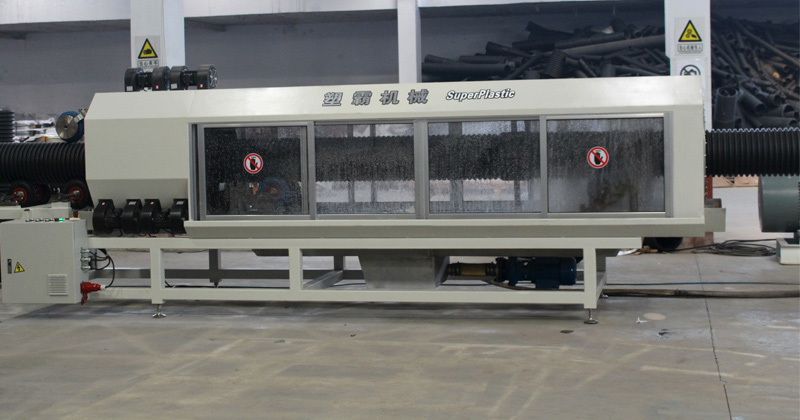

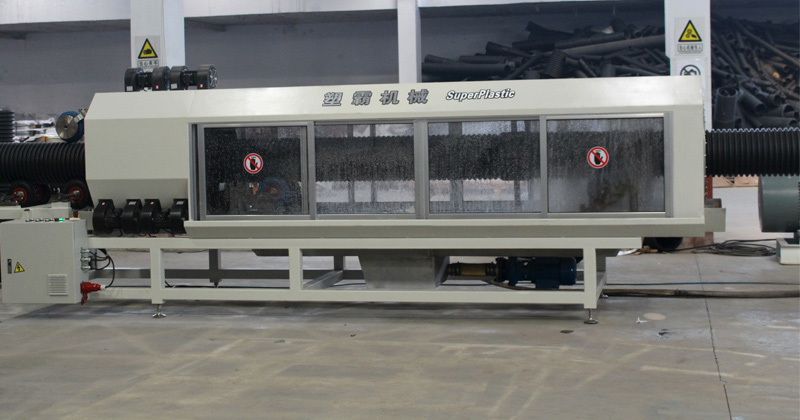

Water cooling high speed double wall corrugated tube making machine from Suba machinery.

Pipe diameter ranges from ID90 to ID1200mm. The model SL300 could proudce pipes from ID90mm to ID300mm.

Model | SL300 | SL600 | SL800 | SL1000 | SL1200 |

Suitalbe pipe range DN/ID(mm) | 90-300 | 110-600 | 200-800 | 300-1000 | 600-1200 |

All the mould blocks are compatible |

Suitable material: PE/PP/PB/ABS/HDPE Etc

Raw material: New or recycling material

Pipe type: Double wall corrugated pipe

Field of application:

* Sewer pipes

* Drainage pipes for fields, streets, squares, buildings

* Cable protection for TV, telephone, glass fiber, electricity, IT and computer.

* Structural and civil engineering

Cooling type: Patented closed loop water recycled cooling system

Machine advantages: With the newest and patented technologies, achieving the high production speed with low energy consumption. High speed, energy saving, easy operation.

More features about the dwc pipe extrusion line:

Extruder:

* The innovative design of buffer system decreases the main drive motors power needs, extrusion system reduces 30% electrical consumption.

* The extrusion system with a large L/D ratio(36:1) allows for high efficiency and stable extrusion.

Die head:

* Cross section optimization of extruder head ensures the pipe production in low temperature and low pressure.

*Pipe wall thickness adjusting structure (patent invention) ensures the extruder head can be adjusted directly no need to loosen any fastening screws and no need to stop the whole machine.

Mould blocks:

* Direct and process controlled water cooling

* Compatile from SL300 to SL1200=Less investment costs and no changes in product design

* Vacuum system

* Quick mould block change system

Forming machine:

* Open design

* No platform design

* Process controlled direct water cooling of mould blocks

* High outputs

* Quick opening of center channel via spindles

* Mould blocks compatible to other models

* Easy and quick mould block change

* Precise lateral and height adjustment of corrugator

* PLC control system

* Touch screen technology

* Electrical control for synchronisation with extruder

Cooling tank:

* Water is totally recycled

* High pressure and volume dryers

* Electrical control for synchronisation with forming machine

Cutting machine:

* Dual cutting blades

* Dual hydraulic station

* Synchronized with cooling tank

Stacker:

* Height adjustable to speed performance & decrease worker fatigue.

* Pipe can be stored on stacker or easily transfer to storage cart.

Contact information:

Eric Zhang

Mob/WhatsApp: +86 13375369566 Email: eric.zhang@subamachinery.com.cn

Qingzhou Suba Machinery Co., Ltd