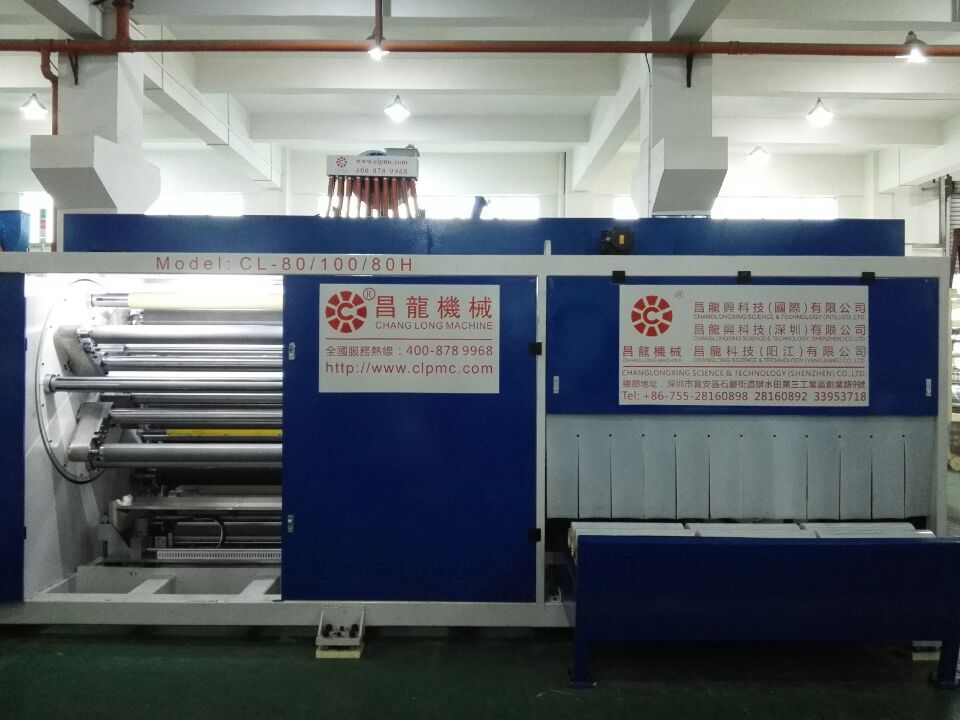

Big Rolls Machinery Stretch Film Production Line Style CL-70/100/70A

This style machinery stretch film production line adopts PE, LLDPE as main raw material and can be mixed with other auxiliary materials to produce the single-side or double-side self-sticky PE stretch wrapping film.The stretch film produced by this unit stretch film production line has good tensile strength,anti-pricking ability and impact strength.

Big Rolls Machinery Stretch Film Production Line Features

1.High output ,save energy and easy to operate.

2.Material: 38CRMOALA special high quality alloy steel, surface precision nitriding treatment.

3.This cast film maker with Melt Metering Pump which uses sensor technology,precise control uint extrusion

pressure to achieve a linar extrusion ,improve film properties.

4.Adopted high precision Double Layer Strong Exhaust Vacuum Box Device to abosord the hot air between

T-Die and cooling roller to make cooling well,especially in high speed running.

Stretch Film Application

The stretch film made by this cast film maker has a good shrinking memory function and self-sticky can make goods integrity to prevent goods from loosening and collapsing during transportation and being polluted by dust.The film can be widely used in wrapping of palletized goods.

Our Big Rolls Machinery Stretch Film Production Line all comprehensive through the CE Quality Certification and ISO Quality System Authentication

Big Rolls Machinery Stretch Film Production Line Delivery

After-Sales Service

We possess a professional and young management and technical team, our service net covers all around the world, the rapid and convenient service will meet your demands.

1. 12 months warranty period , lifelong maintenance services , engineer to door maintenance.

2. Senior engineer installation guide & operator train.

3. Machine instruction , ready access.

4. Technical service team , 7*24h telephone service.