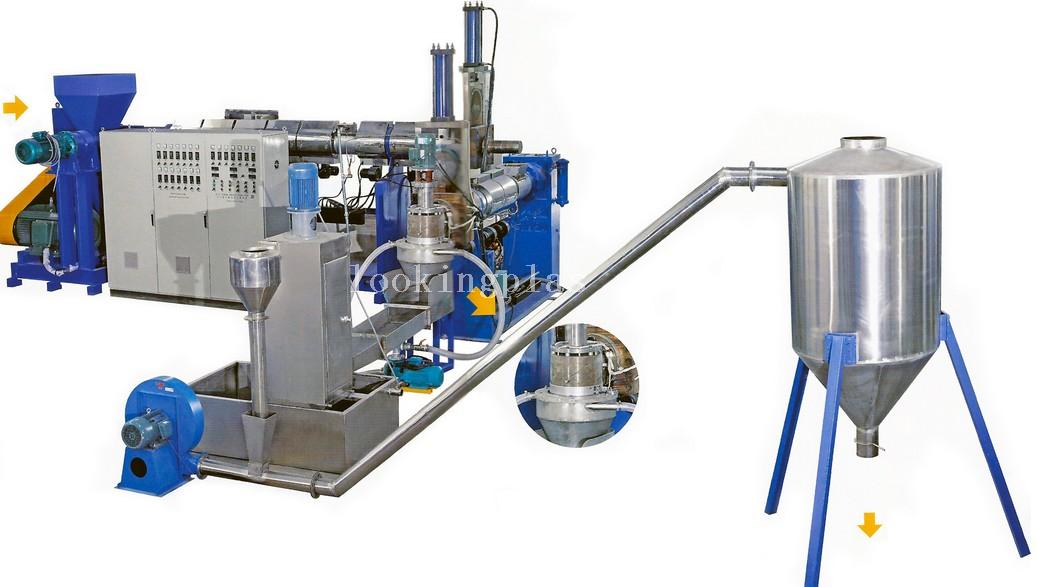

Product Description:

Customers can select a suitable machine among double segment style, three-segment style, and four-segment style based on production needs. The special designed granulator machine can ensure great compounding effect and more solid pellet. This kind of granulator machinery is especially suitable for recycling dirty waste and production of PP PE pellets.

Features:

Gear box: high-torque design; low noise; smooth running

Special barrel design can ensure better compounding effect in order to reduce the problem of black point and chromaticism.

Equipped with a force feeder and hydraulic screen changers according to material’s special character, it can get a better capacity and save more power.

Vacuum or common gas exhaust system that help get rid of damp moisture, waste gas, impurity, and ensure a more stable extrusion and more solid pellets.

Main Specifications:

| Model | FXDN-100/100 | FXDN-120/120 | FXDN-150/150 | FXDN-180/1800 |

Main Extruder |

| L/D | 25-30 | 25-30 | 25-30 | 25-30 |

| Main motor power(kw) | 45-55 | 55-75 | 75-90 | 90-110 |

| Heating power (kw) | 40 | 45 | 55 | 70 |

| Rotational Speed (rpm) | 0-120 | 0-120 | 0-110 | 0-110 |

Second Extruder |

| L/D | 10-15 | 10-15 | 10-15 | 8-15 |

| Motor power (kw) | 22 | 30 | 37 | 45 |

| Heating power (kw) | 25 | 30 | 35 | 45 |

| Rotational Speed (rpm) | 0-120 | 0-120 | 0-110 | 0-110 |

| Output (kg/hr) | 250 | 350 | 500 | 650 |