1. Electric system: Mitsubishi PLC system and human-machine interface control (Chinese & English language). Touch screen operation. Setting parameters , changing parameters, searching, monitoring, fault diagnosis and other functions are done by the touch screen. Components are durable.

2. Hydraulic system: Proportional pressure control. Using international famous hydraulic components. It is steady and reliable.

3. Plasticizing system: Two IKV high efficiency of plasticizing mixing screw. Make sure the plasticizing fully and evenly. Output is more than 700kg/h.

4. Speed control system: Variable-frequency speed control and alloy steel hard tooth-face speed reducer. Speed control steadily. Low noise. Durable in use. It can tiny-open to make sure enough mold-lock pressure. Mold-open steadily. This system is TONGDA patent.

5. 2000L robots: Double air cylinders drive independently. Cycle cooling water. It can take weight product.

6. Die head: Accumulator flat die head. This is good for making plate type blow molding products. Accumulator is external mode and this is convenient to adjust parameters during producing. Flow is streamlined design and it can reduce the effect on the melt. This is TONGDA patent.

Bottom blow pin: Bottom blow pin is put under the clamping unit. It can pre-blow and molding blow.

7. Convenient to change mold: Clamping unit can be moved right and this is convenient to change the mold.

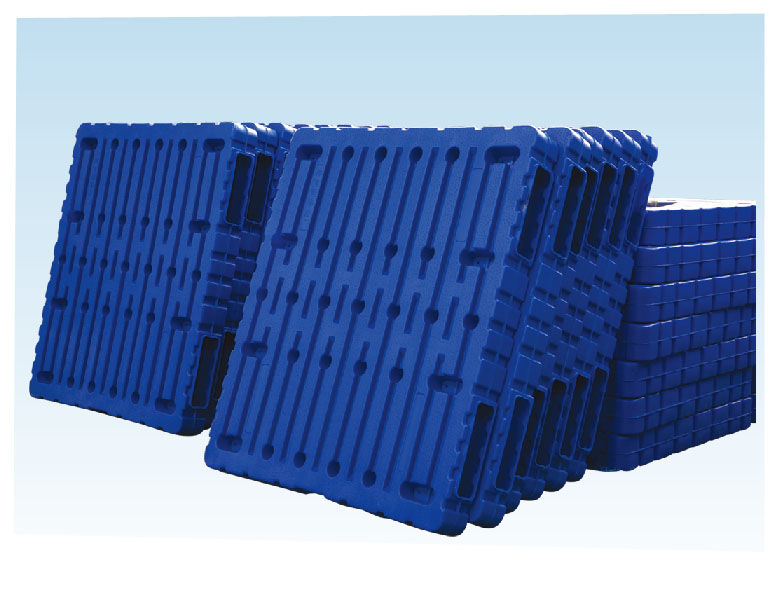

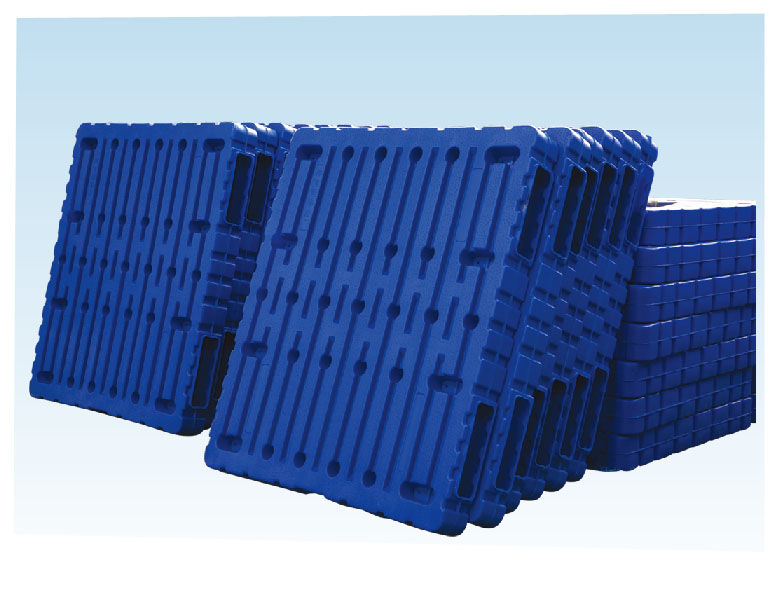

8. Low-energy: Produce 1400*1200*150mm pallet, the energy consumption is about 20KW.h for one piece. This energy saving is international advanced.

| Model | / | TDB-1200L | TDB-1600L | TDB-2000L |

| Max.Product Volume | (L) | 1200 | 1600 | 2000 |

| Station | / | Single | Single | Single |

| Dry cycle | (pc/h) | 30 | 30 | 30 |

| Screw Diameter | (mm) | 150 | 120*2 | 120*2 |

| Screw L/D ratio | (L/D) | 32 | 32 | 32 |

| Screw drive power | (KW) | 200 | 132*2 | 132*2 |

| Screw heating power | (KW) | 70 | 23.6*2 | 23.6*2 |

| No.of heating zone (Screw) | (ZONE) | 7 | 6*2 | 6*2 |

| Output of HDPE | (kg/h) | 550 | 350*2 | 350*2 |

| Hydraulic pump driving power | (KW) | 30 | 11+15=26 | 11+15=26 |

| Clamping force | (KN) | 1500 | 2000 | 3000 |

| Platen distance | (mm) | 1100-2700 | 400-2000 | 400-2000 |

| Max.Size of Mold | (W*H) (mm) | 1860*1720 | 1600*1800 | 1600*2000 |

| Capacity of Accumulator head | (L) | 45 | 70 | 100 |

| Max.Die diameter (Single-head) | (mm) | 750 | 1400*120 | 1500*120 |

| Die heating power(Single-head) | (KW) | 45 | 90 | 95 |

| No.of heating zone (Single-head) | (ZONE) | 9 | 24 | 30 |

| Blowing pressure | (Mpa) | 1 | 1 | 1 |

| Air consumption | (M³/MIN) | 5 | 5 | 5 |

| Cooling water pressure | (Mpa) | 0.4 | 0.4 | 0.4 |

| Water consumption | (L/MIN) | 350 | 350 | 350 |

| Size of machine | (L*W*H)( m) | 10.6*3.5*5.6 | 11.5*9*6.9 | 11.5*9*7.2 |

| Weight of machine | (TON) | 45 | 70~75 | 70~75 |