●Basic installation including

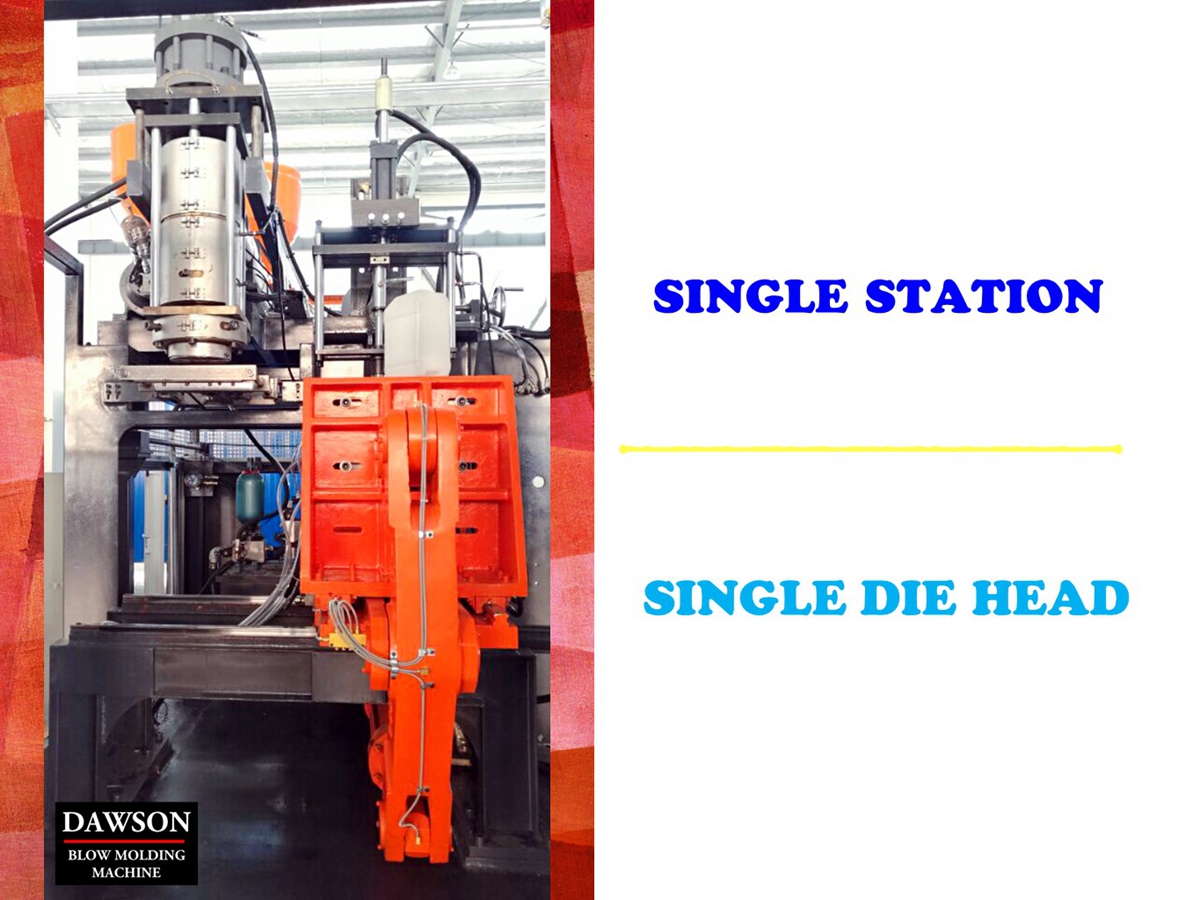

● Die head: Center-feed die head

● Extrusion system: Adopt world-famous brand automatic temperature controlling device. Drive the screw with electromagnetism motor reducer to realize stepless regulating.

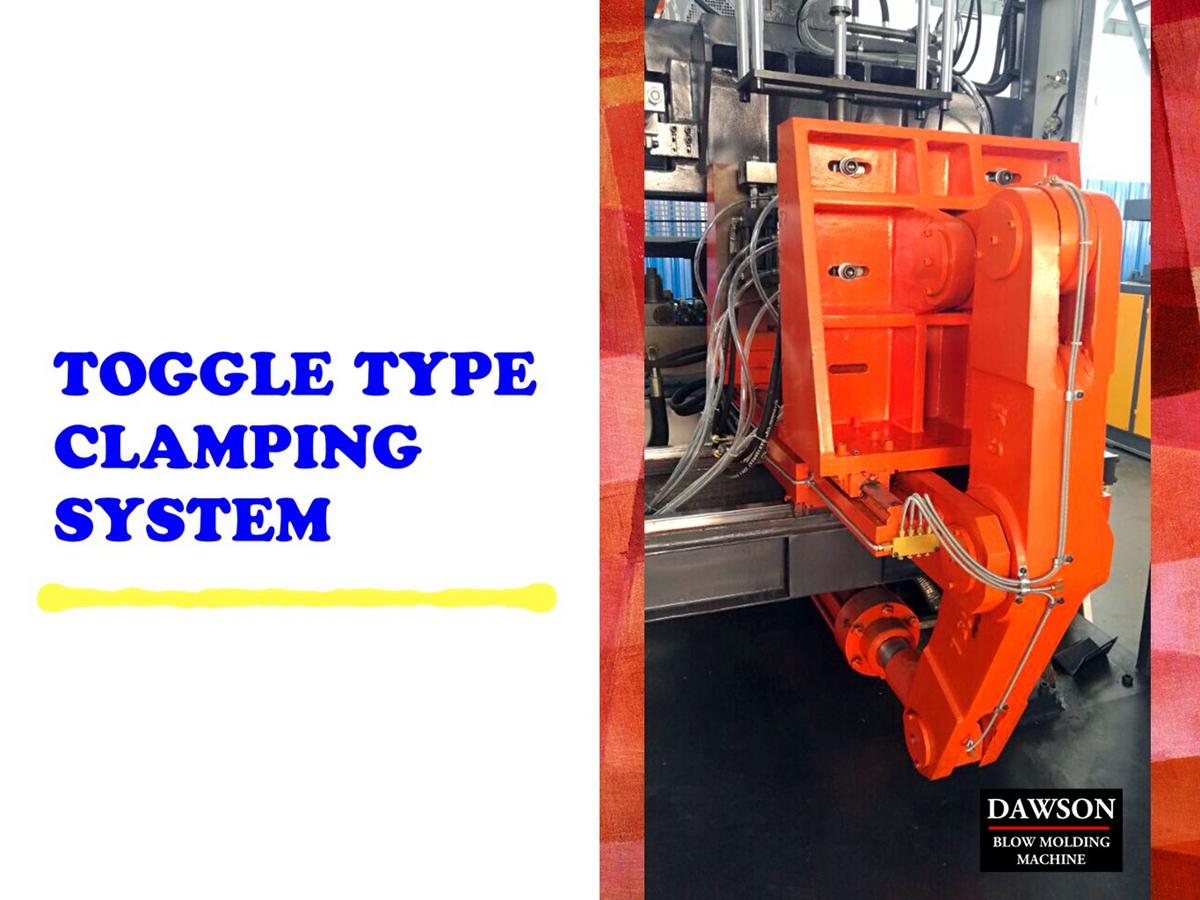

● Clamping device: Adopt bi-directional synchronous clamping device with double axis single cylinder to stabilize equipment well

● Blowing device: with upper blowing type

● Hydraulic system: The whole hydraulic system adopts world-famous brand controlling components and proportional controlling circle.

● Electric controlling system: Adopt programmable controller made in Mitisubishi , Japan. Every electric component is of world-famous brand.

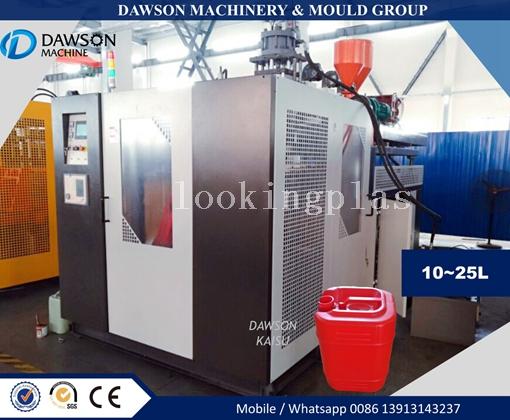

●CONFIGURATION: DSMH-25L

electronic parts |

Name | Trader |

Parison Control system | Japanese MOOG 100 points |

Micro computer control system | MITSUBISHI/TECH-2 |

Temperature Controller | OMRON |

Auxiliary Relay | OMRON |

contactor | Schneider from France |

Main Power Switch | Schneider from France |

Approach switch | Schneider from France |

Electric motor | SIEMENS |

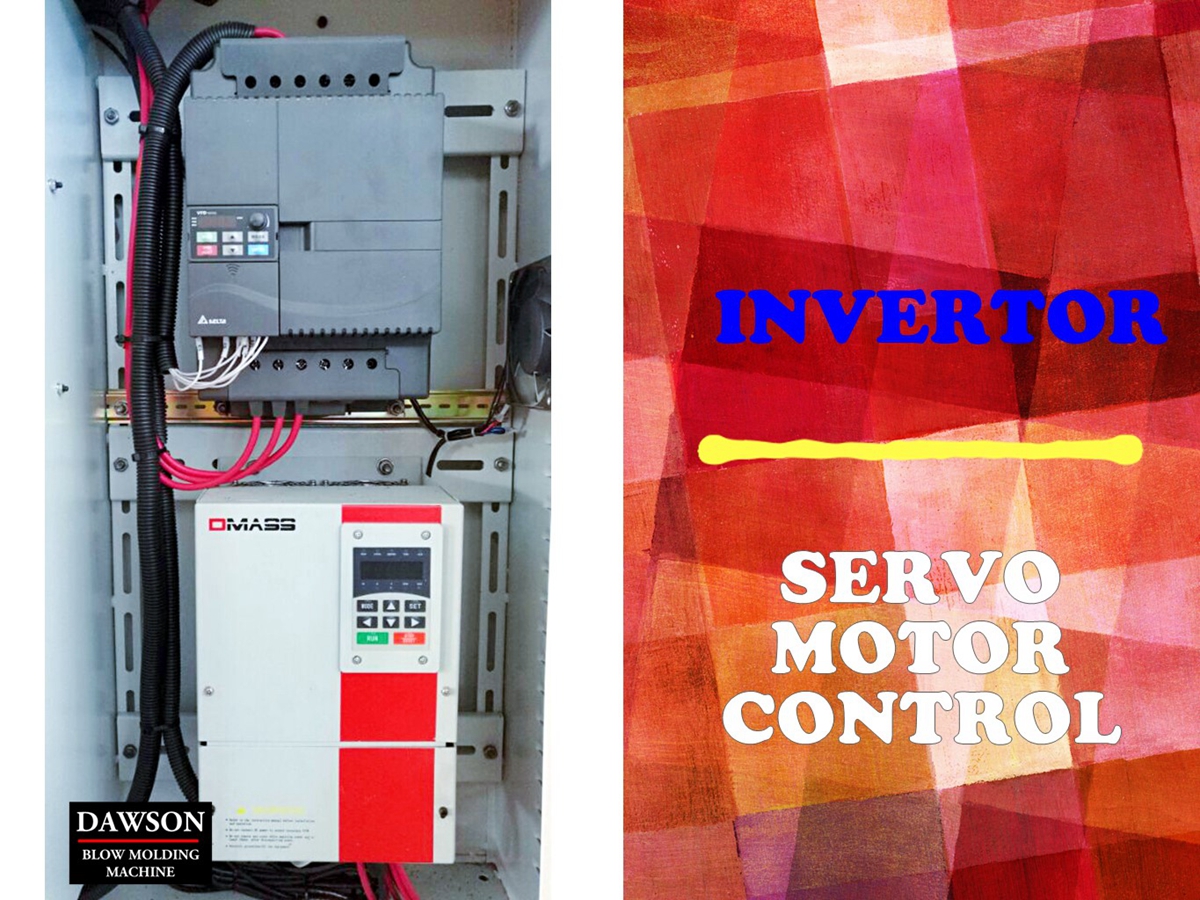

Inverter | ABB/DELTA |

hydraulic parts |

Oil pump | TAIWAN HYTEC |

Valve | JAPAN YUKEN |

Oil pump and connection | JAPAN YUKEN |

Sealed part | TAIWAN HALLITE |

air control system |

Cylinder | AIRTAC |

Air Valve | AIRTAC |