About Qingdao Great Machinery Co., Ltd

With the occupying area of 10,000 ㎡, the company possess more than 40 emplyees and the supply ability blow molding machines are 50 sets per year. Our machine water tank capacity are from 200L to 10,000Liter, which can produce water tanks, pallets, road barrier, IBC, dustbin, chairs, table top, tool box and other customized products.

Armed with advanced technology from Germany and Italy, our company become one of the professional manufacturer of Large blow molding machine in China. We are using DMASS servo motor from Germany, which reduce the power consumption to by 30%-50% of common motor. It uses blow molding tech and is the most advanced plastic machine in the world.

Our blow molding machine are exported to India, Kenya, Jordan, Saudi Arab, Iraq, Asia, Middle east, Africa, Latin America.

As we are offering the great quality of water tank blow molding machine which is running at low power consumption and trouble free operation and our team offers great after sales service to all of our customers, that help us to build up a great reputation in the global market.

Features of blow molding machinery:

l One/Two/Three layers of plastic tank blow molding machinery can make one/two/three layer of water tank by the same tank making machinery

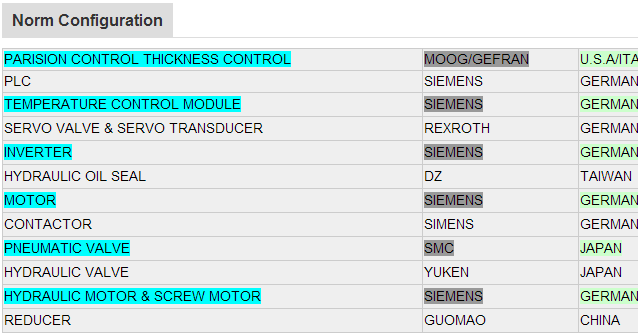

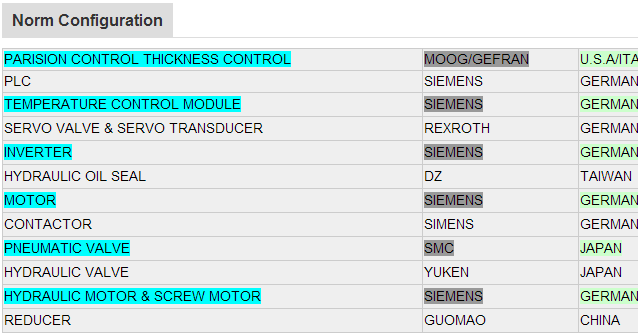

l All electrical components using SIEMENS brand name.

l Using SERVO motor drive on extruders to adjust speed quickly for changing parison weight, screws with special design.

l Two pulling rods clamping structure with stable operation

l Two hydraulic stations by SERVO drive to acquire energy saving

l PLC touch screens(wall thickness and machinery operation touch)

l Head die with spiral flow channel design without weld point

l Pneumatic system has function of silencing

Machine Features:

1.The screw adopts IKV design, with high potency melt to make sure the material well mixed.

2.Adopt frequency control of motor system to reduce the power consumption.Adopt Parison thickness controller Moog 100 points, to make thickness even and adjust the tank weight in big span.

3.Fully automatic, easy to operate, two women can operate machine, whole production line need 3 or 4 person only.

-High output versus Roto molding machine

-Save raw material 25% - 35% versus Roto tanks.

-Perfect impact resistance versus Roto tanks.

-Multi layers co-extrusion.

INSTALLATION & ADJUSTMENT

The Seller could dispatch an engineer against the requests of the Buyer to install and adjust the machines for one week in the Buyer’s factory.

The Buyer should make a reservation in advance before delivery of the machines;

The Buyer should pay for the engineer’s visa application cost, round air tickets, food & board before his departure;

GUARANTEE

The guarantee time is one year after the machines normally works in the Buyer’s factory, if only the problem is cause due to quality control or any reason by the Seller. We will supply replaced parts free of charge and our engineers will guide you how to solve the problems.

Any problem caused due to irregular operation or incorrect maintenance by the Buyer won’t be listed in guarantee coverage.