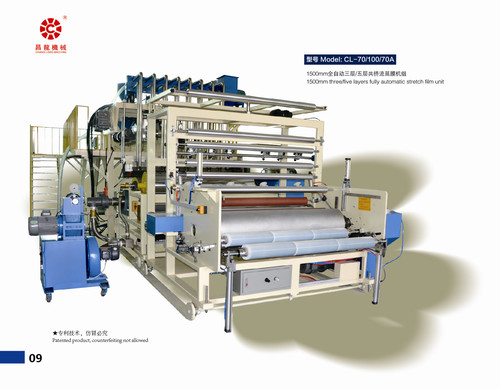

Extrude Machine For Plastic Film Cast Film Production Machinery CL-70/100/70A

Combined with Italy and Amercian high-tech to produce high plasticity,this machine is based on

our long time manufacturing experience and customer's actual operate, designed for three

or five layers stretch film , cling film , and protective film, which is very easy to operate.

Main Technical Parameter:

Model: CL-70/100/70A

Width of Die Head: 1850mm

Width of Film: 1500mm

Thickness of Film: 0.01-0.05mm

Structure of Film Layers: A/B/C or A/C/B/C/A

Liner Speed of Machinery: 200m/min

Max Extrusion Capacity: 380kg/h

Max Rewind Diameter: 400mm

Screw Diameter: 70/100/70mm

L/D Ratio of Screw: 30:1

Motor Power of Main Machine : 37/90/37kw

Total Power: 50-220kw

Overall Dimensions(L*W*H): 11.5*4.3*4.5m

Total Weight : 18.2T

Features

1.Melt metering pump unit uses sensor technology,precise control uint extrusion pressure to achieve a linar extrusion ,improve film properties.

2.Vacuum devices make the production of film better fit confluemce extended cooling reel,better coolng effect ,improve film performane.

3.Installation of fence around the screw stairs,user friendly design,easy to operate those machines at any time to view the situation.

4.Touch screen centralized control,interpersoal friendly interface,simple operation,and more intelligent.

5.Casting film production crew uniform thickness,good tensile strength,strong puncture resistencee,

especially for high-end machine with high quality requirements.

6.Casting cooling section with large shaft diameter double-loop cooling system,cooling reel

surface temperature uniformity,to improve the cooling effect.

Workshop

Application

The machine's film can be widely used for goods packing, manual packaging and so on.

Certificate

Packing

After-Sales Service

We possess a professional and young management and technical team,

our service net covers all around the world, the rapid and convenient service will meet your demands.

1. 12 months warranty period , lifelong maintenance services , engineer to door maintenance.

2. Senior engineer installation guide & operator train.

3. Machine instruction , ready access.

4. Technical service team , 7*24h telephone service.