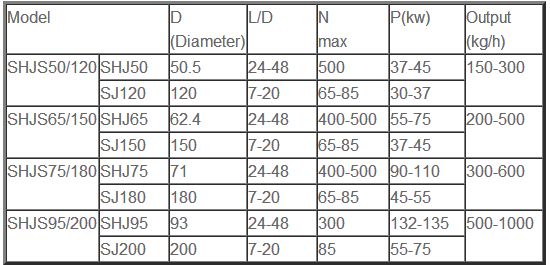

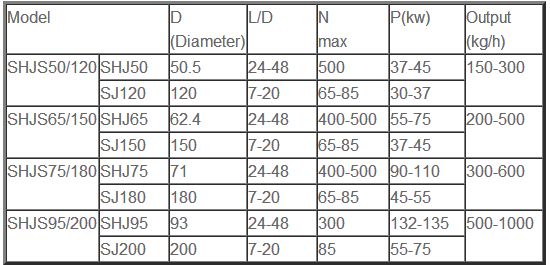

SHJS series two-stage machine characteristics

Structure:

Stage one is SHJ high-speed co-rotating twin-screw extruder.Stage two is SJ low single screw extruder.Two parts are placed vertically.

Principle and applications:

SHJS series two-stage extruder makes use of the advantage of twin-screw extruder and single screw extruder adequately. Twin-screw extruder realizes transportation,high effective plasticating and compound dispersion. Sigle screw extruder achieves better materials extruding.

Increase the operation variables and realize the process because of two-stage machine. Meanwhile higher efficiency and production capacity can be realized.

Two-stage machine is good at processing heat-sensitive material and devolatilization operation, such as PVC,XLPE,Zero halogen cable,shield material,carbon black etc.

This is another application of SHJS tendem line.

Together with special low pressure and short channel die as well as eccentric dieface cutting technology ,

the tandem line is capable of effectively mixing/compounding PE resins, antioxidants and peroxides etc .

at a low temperature ,to minimize premature crosslinking of polyethylene .