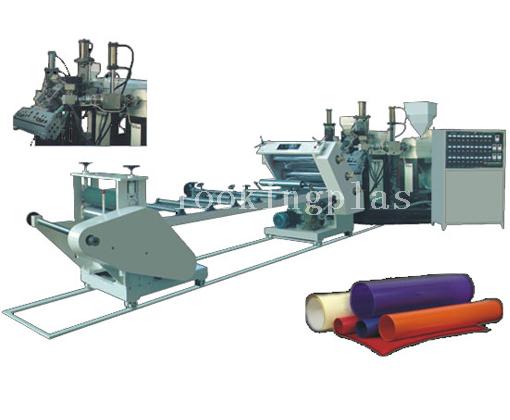

Features:

1, screw, rod tube, the mold top the main components 38CRMOALA alloy steel materials, and by the nitrogen treatment, wearcorrosion and other advantages.

2, The machine adopts the three screw Freemasonry can be three to five Masonic functions. Can greatly reduce themanufacturing cost of the sheet can be scaled back to the material and filler added to the host, does not change the shape ofthe sheet and molding effect.

3 die heating mode, the screen changer with hydraulic duplex digital device, no downtime can change the network to facilitatethe operations to improve production efficiency. The plastic sheet unit is basically designed to absorb advanced technology,manufacturing. This machine is suitable for the production of polypropylene (PP), polyethylene (PE), polystyrene (PS) and otherplastic sheet.

Main technical parameters:

Processing materials PP, PE, PS, HIPS,

Forming sheet thickness (mm) 0.3 ~ 2.0

Sheet thickness accuracy ≤ ± 0.015 0.8mm more than ≤ ± 0.010 0.8mm below

Effective width of the sheet (mm) ≤ 710

Output of 250kg / h

Maximum roll diameter (mm) 700

Hierarchical number

Roller specifications Ф350 × 800 three

Machine rated power (kw) 90

Dimensions (mm) 12000 × 1500 × 300000