★Performance:

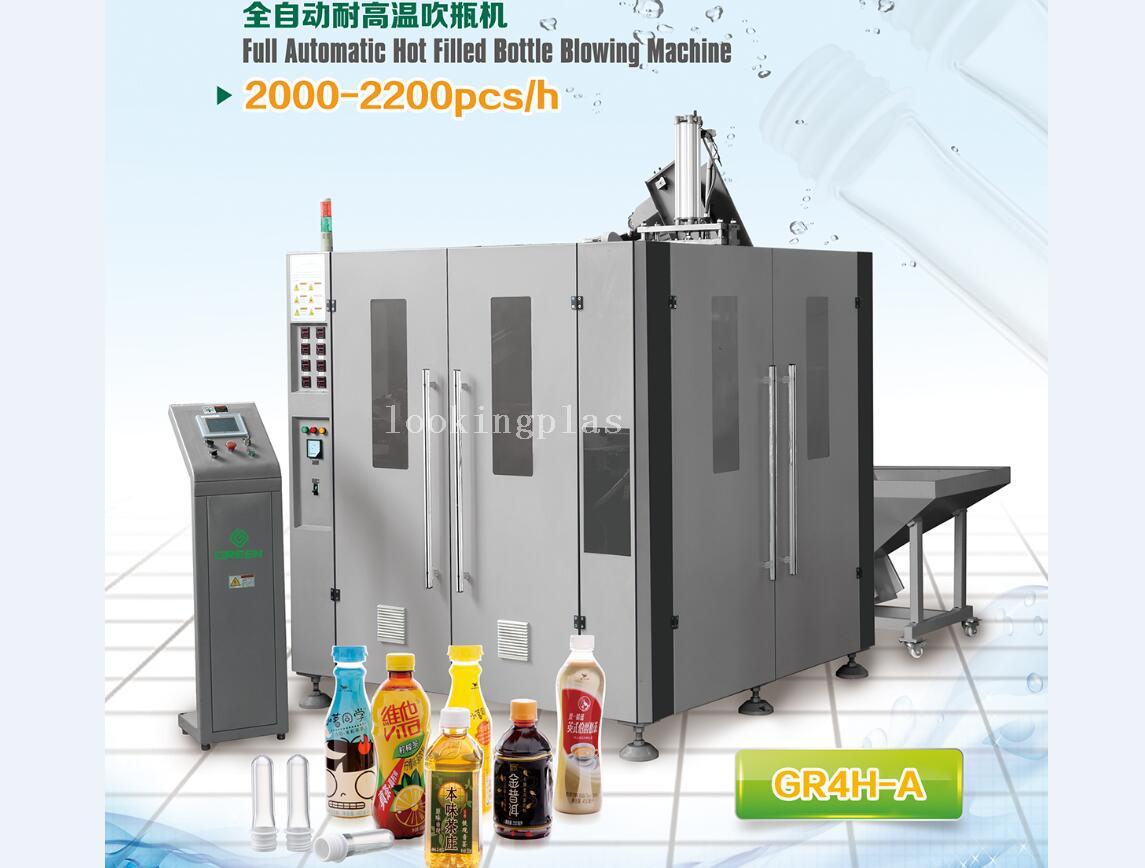

GR4H-A is suitable for the production of PET bottle blowing:hot filled bottles(juice bottle)and a variety of carbonated beverage bottles, mineral water bottles, oil bottles, medicine bottles, cosmetic bottles, cosmetic containers.

☞The control system adopts the international advanced integrated computer intelligent control system, which has the advantages of high control accuracy, fault self diagnosis, intelligent monitoring, data management, graphical fault display and so on.

☞The man-machine interface and the analog switch are combined with the double operating system configuration, which is convenient for the system to be replaced during maintenance.

☞The system is equipped with a device to prevent the leakage of the material overflow recovery device, completely eliminate the phenomenon of material blocking.

☞Oven heating system using digital instrument driver thyristor to realize voltage control, oven with hot air circulation system, heater using infrared lamp, heat radiation, high efficiency, and can freely adjust the radiation area.

☞The bottle embryo is elastic and embedded, which can protect the bottle mouth.

☞The use of rapid diaphragm type air blowing valve with a unique progressive blowing method to ensure product quality stability. The high and low pressure road separate laying, greatly improve the stability and safety of the machine.

☞direct acting pneumatic locking, adjustable, no abrasion, high reliability and maintenance free.

二、★ The main configuration (our choice of the world's leading suppliers of components) :

三、★Technical parameters:

model | GR4H-A |

Capacity |

up to bottles | 2000-2200pcs/h |

Bottle size | Volume | ≤1.5L |

Diameter | ≤90mm |

Height | ≤310mm |

Neck diameter | ≤30mm |

Power | Power voltage | 380V/220V 50/60HZ 3phase |

loading power | 49kw |

Running power | 13kw |

Main-machine | Size(L×W×H) | 1900×1860×1930mm |

Weight | 3800kg |

Preform unscrambler | Size(L×W×H) | 2000×950×2480mm |

Weight | 250kg |

Air Source | HP Air compressor | 4.0m3/min 4.0Mpa |

LP Air compressor | 2.0m3/min 1.0Mpa |

air source purification | Air dryer | 4.0m3/min 4.0Mpa |

oil water separator | 4.0m3/min 4.0Mpa |

Pre-filter | 4.0m3/min 4.0Mpa 0.1um |

Precision filter | 4.0m3/min 4.0Mpa 0.01um |

Ultra precision filter | 4.0m3/min 4.0Mpa 0.001um |

active carbon filter | 4.0m3/min 4.0Mpa |

Cooling water | water chiller | 3HP

|