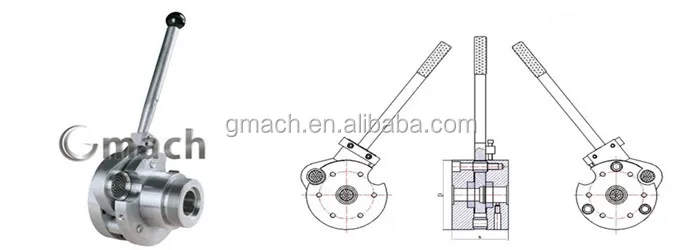

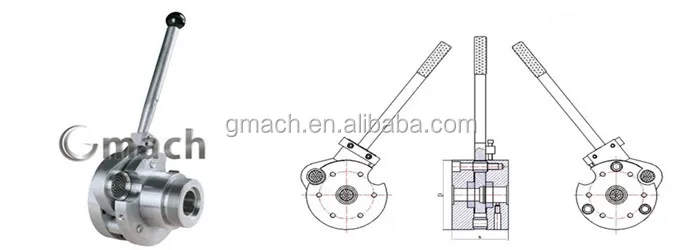

Lab mini extruder used plastic manual screen changer

GM-MSPG series

This GM-MSPG series plastic extruder screen changer manual screen changer now is not so popular in the extrusion fields, because more and more people choose the automatic screen changer which is less labor interferrence, such as the plate type hydraulci screen changer, dual rods continuous screen changer,or plate type continuous screen changer.

But this kind of plastic extruder manual screen changer is still used on some smalland low-output extrusion machine, such as the mini extruder in lab, laboratory extruder.,some small plastic recycling machine.very small pipe extruer

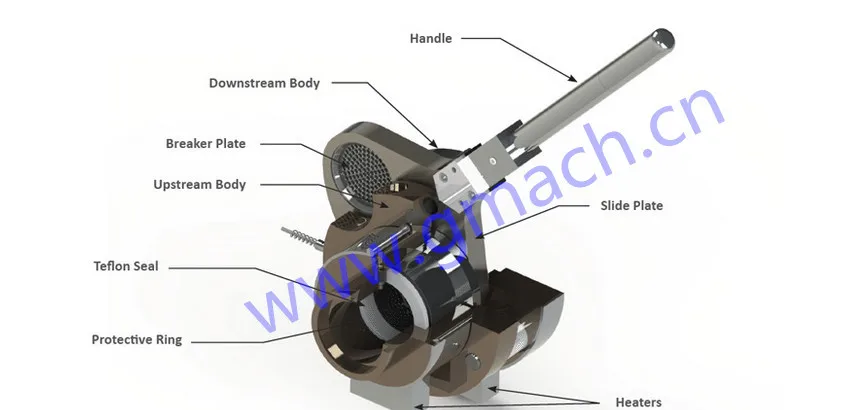

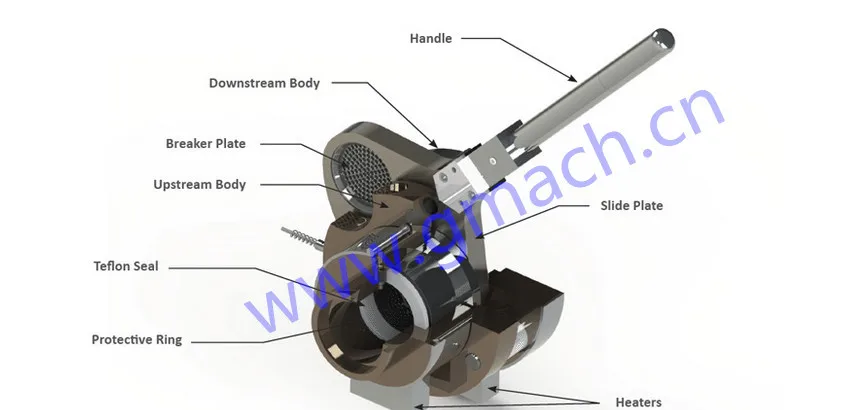

Structure

The body of the screen changer

The breaker plates(two or more)

the heating elements

Temperature and pressure transducer

Benifits

Flexible, easy to install or removeble

The operation handle/bar position can be adjusted

Precise location of the screen ensure the melt stream fluently

Types

Type | Screen D&A | Overall dimension (mm) | Heating power (KW)) | Output

(kg/h) |

| Diameter (mm) | Filter area (cm²) | D | W |

|

|

GM-MSPG--40 | Φ50 | 20 | 200 | 140 | 1.7 | 30-60 |

GM-MSPG--50 | Φ50 | 20 | 200 | 150 | 1.7 | 35-70 |

GM-MSPG--60 | Φ60 | 28 | 255 | 170 | 2.5 | 60-180 |

GM-MSPG--70 | Φ70 | 38 | 255 | 170 | 2.5 | 80-180 |

GM-MSPG--80 | Φ90 | 64 | 300 | 175 | 3.0 | 100-180 |

GM-MSPG--90 | Φ90 | 64 | 300 | 175 | 3.0 | 110-180 |

GM-MSPG--100 | Φ100 | 78 | 320 | 180 | 4.2 | 120-230 |

Remark:The output is depend on the extrusion process. |

Finished products

Lab mini extruder used plastic manual screen changer

Application show

Plastic extrusion machine filter part manually operated screen changer

Packaging & Shipping

Packaging

Inner packaging:bubble protection wrap film

Outer packaging: wooden case

Shipping : The cargo can be deliverd by sea or by air as the request of customers

Our service

Commissioning

We provide the operation manual for customers to gudie to install the screen changer, and at the requirement of user, salers should send technician to install and commissioning the die at site of Buyers, expenses of the trip should be borne by Buyers.

After-sales service

12 months with proper operation by user, all the spare parts shall be replaced free of charge under guarantee period, fee for transportation and packing will be borne by users.

Company Information

FAQ

What are the benifits of screen changer on extruder?

1, improve the quality of the final products

2,greatly improve the plasticizing of the raw material

3, make the product structure more homogeneous and product surface smoothness

4, protect the down stream equipments, such as Gmach melt pumps and the extrusion dies

What are the benifits of melt pump on extruder?

1, to improve the stability of the product size

2,melting quality control

3, increase output

4, reduce the raw materil consumption

5, improve the flexible of the extruder

6, protect the extrusion die ,extend the service life of the extruder

What are the benifits of installation the screen changer and melt gear pump together?

1, improve the melt plasticaction

2, improve the quality of the products

3, extend the service life of the extruder

4, greatly increase the output of the products

5, reduce the labor interference

6, reduce the unqualified products

What do we need to pay attention when using the screen changer nad melt pump?

1, we should operate the screen changer and melt gear pump as the safety manual, prevent an electrical shock

2, To prevent ourself scald

3, do not disassemble the screen changer and the melt gear pump, any questions, please contact with the supplier.

Tips for customers

How to choose a most suitable type of screen changer for your extrusion line ?

After the equipment supplier making a size recommendation and then you should perform your own analysis to confirm appropriate sizing. That way, you will have the advantage of independent analyses and, best of all, there is no additional cost.

Learn the difference between price and cost. Be sure to take into consideration all of the variables and look at all the factors to determine the real cost of ownership for the screen changer. Some of the hidden variables to consider may be:

•Product quality.

•Maintenance, time and cost of parts.

•Process downtime and cost.

•Life expectancy for the equipment and amortized cost of ownership.

•Cost and availability of filtration media.

•Pressure loss and effect on line output and product quality.

•Operator safety.

•Required operator intervention and labor cost.

If all of these and other factors are taken into consideration, you can choose the most suitable solution, and then you can expect a much better return on investment.