Product Description

Slide plate type hydraulci screen changer for large flow rate extrusion line

1, the structure and working princple of this kind of Film blowing machine used hydraulic fast screen changing filter

This series of screen changer consists of main body, sliding plate, heater unit and

hydraulic unit with accumulator. It is driven by hydraulic system, and the sliding plate

carrying 2 pieces of breaker plates can move linearly in both directions to

achieve screen changing process smoothly

2,Features of this kind of screen changer

1) Compatible with various extrusion production for most polymers at high pressure, temperature, and production throughput.

2)With highly precise design, the screen has good abrasive resistance, good durability under high pressure,ensuring large effective filtration area and improving filtration performance.

3)It works well even under high temperature up to 300 and high pressure up to 50 MPa.

4)Screen changing process completed in a period ≤ 2 seconds with pressure accumulator.

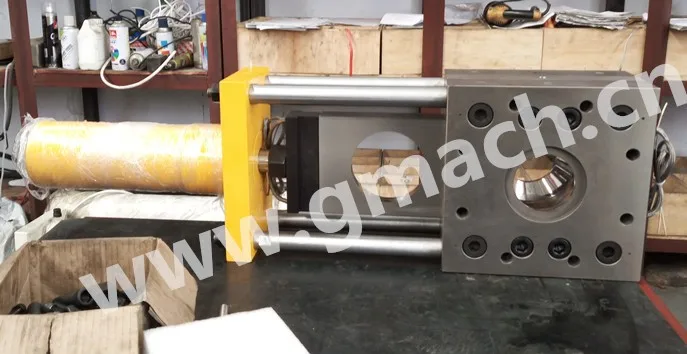

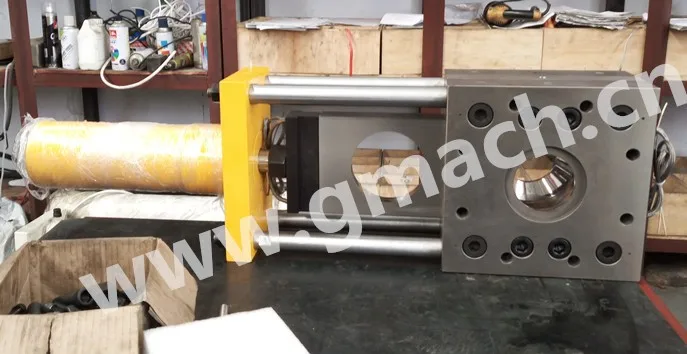

Product show

Slide plate type hydraulci screen changer for large flow rate extrusion line

Benifits of this kind of single slide plate type hydraulic screen changer

Fit for all kinds of polymers

Leak-free mold of operation

Flow channel geometry structure without any dead spots

Several sets of screen changer can be controlled by one set of hydraulic unit

Adapters are talior designed for customers

Variety ways of installation to full use of the limited space

Simply controll by a easy operated control handle

Reasonable price and proved technology

Application cases show

Except use for the filtration of corrguated pipe extrusion machine, this kind flat plate type hydraulic screen changer can be used for many other products extrusion machine.

Main application fields

Film blowing machine and cast film extrusion machine(Bubble wrap film/ Medical/Food Wrap film)

Sheet (Foam/Strapping/Plastic cardboard)

Coating (Hot melt adhesive)

Pipe extrusion machine( Corrugated/Gas Pipe) and profile

Compounding (Master batch/filler)

Wire and cable extrusion

Tubing (Medical/Industrial/Irrigation)

Fibers ( Monofilament/non-woven fabrics)

Blow molding

Pelletizing (strands and water-ring peleetizing)

Recycling of most polymers

Application show

Slide plate type hydraulci screen changer for large flow rate extrusion line

Types

Type | Screen D&A

| Overall dimension(mm) | Heating power

(KW) | Output

(kg/h) |

Dia (mm) | Filtration area(cm²) | L | W | H | L1 |

GM-SSP-70 | Φ70 | 38 | 200 | 170 | 240 | 820 | 3.5/5.8 | 80-200 |

GM-SSP-100 | Φ100 | 78 | 220 | 185 | 280 | 930 | 4.5/6.8 | 150-350 |

GM-SSP-120 | Φ120 | 113 | 260 | 205 | 320 | 1010 | 5.2/7.2 | 220-350 |

GM-SSP-150 | Φ150 | 176 | 300 | 235 | 360 | 1140 | 6.5/8.5 | 350-800 |

GM-SSP-180 | Φ180 | 254 | 320 | 245 | 360 | 1200 | 7.6/9.5 | 550-1250 |

GM-SSP-200 | Φ200 | 314 | 360 | 280 | 420 | 1300 | 8.5/11 | 650-1500 |

GM-SSP-250 | Φ250 | 490 | 450 | 300 | 430 | 1520 | 9.5/12 | 800-2500 |

GM-SSP-300 | Φ300 | 706 | 520 | 380 | 500 | 1660 | 11.5/15.5 | 1200-3500 |

GM-SSP-320 | Φ320 | 803 | 560 | 400 | 560 | 1700 | 13/17.5 | 1500-4000 |

Remark:The output rates depend on the actual individual extrusion process parameters. |

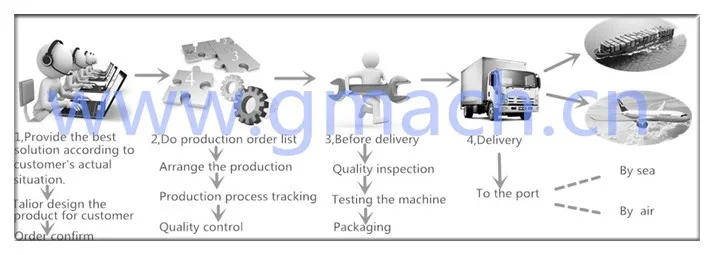

Quality inspection

Our experienced workers will inspect all auxiliary parts of the product , guarrantee that every product from our factory 100 % qualified product.

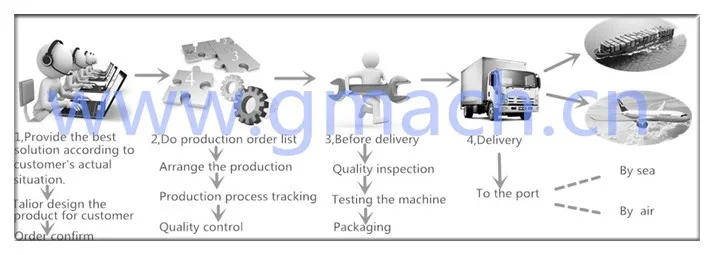

Commissioning

We provide the operation manual for customers to gudie to install the screen changer, and at the requirement of user, salers should send technician to install and commissioning the die at site of Buyers, expenses of the trip should be borne by Buyers.

After-sales service

12 months with proper operation by user, all the spare parts shall be replaced free of charge under guarantee period, fee for transportation and packing will be borne by users.

Company Information

About Gmach

Zhengzhou Great Machinery Co.,Ltd, a high-tech company with deep technology background and strong work team and services in China. Our business across the

1)hydraulic screen changer/ melt filter,

2)melt gear pump,

3)extrusion dies,and

4)plastic recycling granulator.

We do not just supply the products , but also provide

valueadded solutions to more customers in more markets all around the world .

Our goal is help all our customers

1)improve productivity,

2)cut costs,

3)increase energy efficiency,

4)eliminate scrap, reduce cycle times and do whatever else it takes to succeed in today's complex global economy.

Our team is committed to provide customers the best products with ever improving design. Strict production and quality control,and the perfect pre-sales and post-sales services.

We are on the way to be your most reliable and trustworthy partner, now more than ever.

Gmach Factory

Exhibition show

On Chinaplas 2015, our work team and customers

Gmach Certifications

CE Certificate

SGS Certificate

Business License

To our customers

In the end I want to say something to our customers or some one may become our customers I Want to express my thanks to all my dear clients .Thank you for visiting our website and glad to see you. Anyone won't buy any products from strangers until they know each other better, but it's a long time for you to understand a strange supplier well, then how you can find a best supplier during so many factories is a problem! I believe that the honest and sincere is very imporant in the business. Though we are a new member here, but we have a full experience technician team and full sense of responsibilty work team, we will provide all the customers with perfect quality products and service. Thank you so much! ! !