Working principle

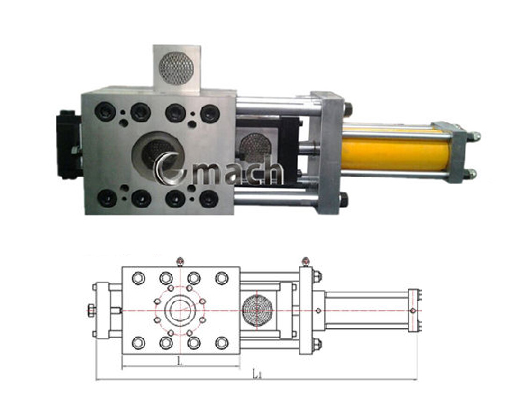

This series of screen changer consists of four independent breaker plates, each with openings of same diameter and screen pattern. The rotation of these specially treated alloy metal plates gives superior sealing ability and durability. This type of screen changer has slight flow fluctuation during screen changing. It can guarantee a continuous and stable extrusion production.

Breaker plates move in the same direction one by one, improved filtration performance, convenient to clean.

Equipped with preheating and ventilation design to minimize the effect of possible temperature, pressure, melt flow fluctuation on polymer during screen changing process.

Benifits

No rupture on film and filament production

Changing the screen without stopping the production

Pressure fluncuation is vey small, ensure the high quality of the products

Easy operation

Technical Data

Type | Screen D&A |

overall dimension (mm) |

Heating power (KW)) |

Output

(kg/h) |

Diameter(mm) | Area(cm2) | L | W | H | L1 |

GM—R-70 | Φ70 | 38 | 270 | 170 | 240 | 850 | 3.2/4.5 | 50-250 |

GM—R-100 | Φ100 | 78 | 375 | 200 | 280 | 1000 | 4.8/7.0 | 320-480 |

GM—R-120 | Φ120 | 113 | 435 | 240 | 320 | 1150 | 6.0/8.4 | 320-600 |

GM—R-150 | Φ150 | 176 | 525 | 260 | 320 | 1400 | 7.2/9.5 | 420-900 |

GM—R-200 | Φ200 | 314 | 700 | 280 | 380 | 1750 | 8.2/11.0 | 500-1100 |

Note: The specifications are subject to change without prior notice.

|