ice cream bottle mold on ibm machines

>>PERATING PRINCIPLE

The core part of one step injetcion and blowing technic is triangular transfer head,The mandrils are asssembled on the side face of the triangular head which turn over to 120degrees.

STATION A:PREFORM INJECTION

The bottle eck will be molded accurately after injecting the material into the cavity,After proper control,the mold open and mandrils to...along with the cavity.

STATION B:BLOW MOLDING

Blowing action was done at this part,molding would be complete after cooling.(bottle shape decides the number of cavity).The air came out from the mandrils huffs the cavity,making the cavity cling to the mold.Then the mold open and the mandrils turn to...along with bottles.

STATION C:STRIPPER

The bottles automatically will be ejected from the core rods at this position and then to be packaed.The three actions of injection、blowing and ejection work at the same time,which makes the machne at high efficiency and low waste with bottles.

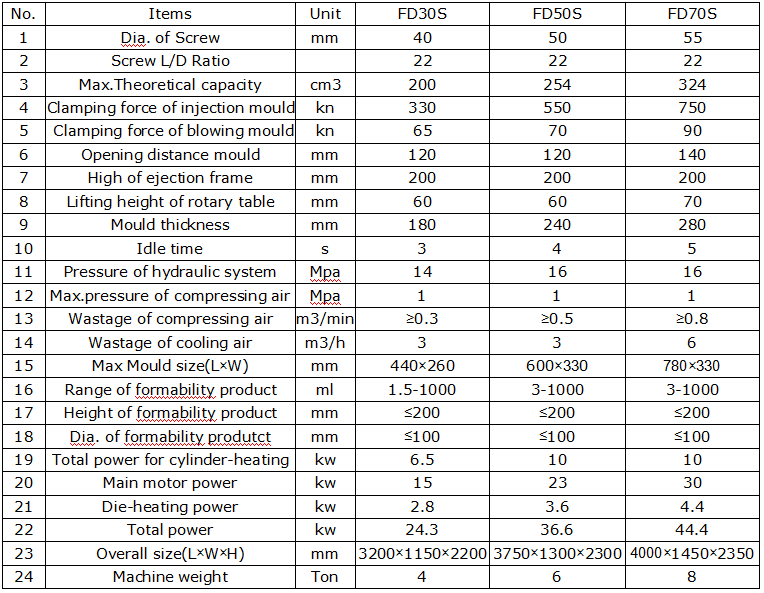

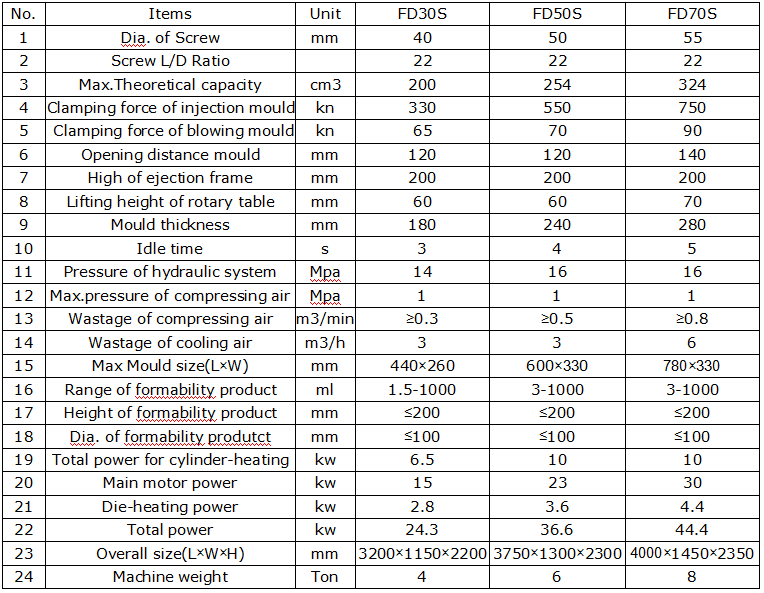

>>MAIN TECHNICAL PARAMETERS

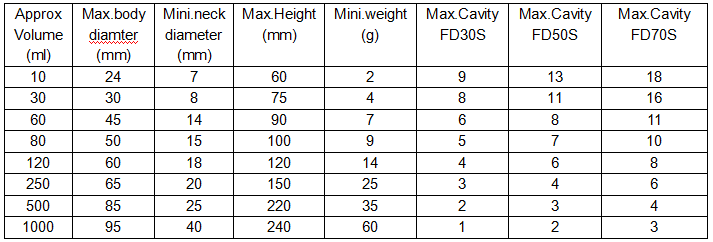

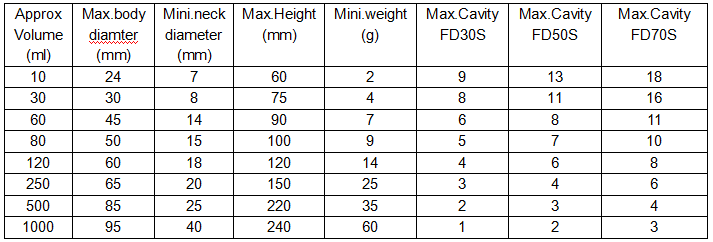

>>REFERENCE OF KINDS BOTTLES WORKING ON EACH MODEL