Brewing is a complex process that combines technology, technology, and art. It is rooted in the strong historical background and cultural tradition, and with the talent of bringing forth new products, it can often pave the way for the application of the most advanced technology.

LONGMAKER and Alfa Laval cooperation on these brewing and fermentation efficiency to ensure the diversification of enterprises competitive to win business success.

At the same time, manufacturers must comply with increasingly stringent laws and regulations, and be able to cope with rising energy costs.

In addition, the brewing process must be flexible enough to respond to changing consumer needs and preferences, standing in the global market to create world-class brand, and realize the production and supply of seasonal products.

Alfa Laval is one of the world's largest equipment manufacturers professional. Our technology is a frontier technology in the brewing industry. Based on most advanced technology and current plant operation practices, we are committed to delivering outstanding solutions.

More revenue - less investment

Brewing is the production of quality products with simple natural ingredients and inputs. Of course, the specific process varies from manufacturer to manufacturer. What's more, the equipment they use is different.

Alfa Laval offers a variety of high efficiency of resource system and technology combination, in order to improve the cleanliness and sustainability of brewing system.

The systems and technologies we provide for Breweries allow the brewery to achieve a delicate production balance as much as possible, thereby increasing production and product quality while reducing the consumption of water, energy and resources.

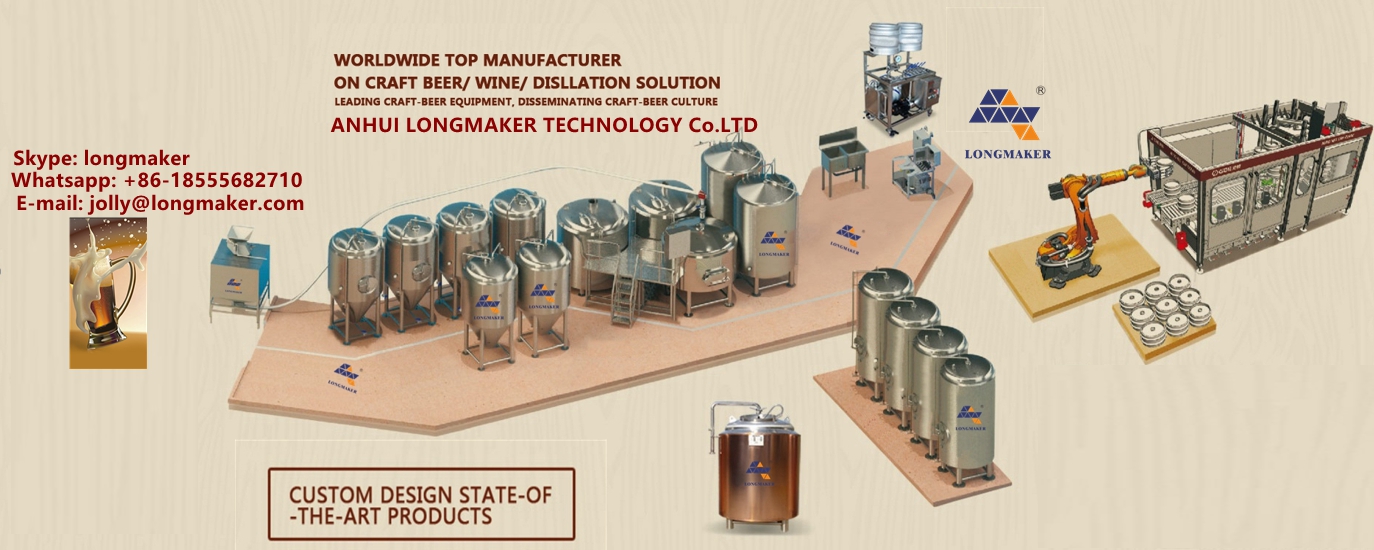

Beer microbrewery equipment 300l small pub brewing plant for sale beer We are the partner of Alfa Laval, Alfa Laval in beer brewing equipment experience is one of the world's top, provides the world's top beer brewing equipment pump, Alfa Laval valves, cleaning device, heat exchanger

The Alfa Laval support, we in the beer brewing equipment manufacturing using high-end technology and accessories is a unique China.

equipment

Packaging & Delivery

Packaging Details:

1.LCL/FCL(20GP/40GP/40HQ)

2.Packed with plastic film in fumigation free wooden case or fixed with iron frame

3.Up to export standard, suitable for delivery

4.Customer's requirements available

Delivery Detail:

about 20~45 working days rely on the capacity and configuration

Product Description

Meto is a professional manufacturer of beer equipment with more than ten years. Wedevote all our energy tomeet your needs on any budget or production target. Our equipment is combined with good quality , beautiful appreance and durable using. Making craft beer .

The complete set of beer equipment includes Malt mill device, Saccharification system,Fermenting system,Refrigerator units,CIP system, Electrical control cabinet and other accessories.

Equipment introduction

Domestic beer brewing equipment, a total yield of saccharification wort 30 rose to 50 liters, the maximum not more than one hundred liters. Beer fermentation tank is generally equipped with 2, the fermentation tank volume generally 30, rose to 50 liters, the maximum not more than 100 liters. All the facilities are integrated arranged in a flat on the platform, the width is not more than 70 cm, length less than 180 cm high, not more than 170 cm. The fermentation process adopts automatic temperature control, the heating of saccharifying process is usually powered by electricity, most of the operations are manual operation, and the timeliness of process operation is generally more extensive. The fermented bacteria can be used as an active dry yeast which can be stored for a long time, and belongs to the self pleasure type beer brewing equipment. The beer quality according to the individual needs of human control, the selection of high-quality malt, brewing water use market to buy high-quality mineral water, further processing technology is simple, the use of high-quality beer, good control of inoculation temperature, fermentation temperature, low temperature fermentation, can produce high quality beer.

Four, product features:

A, the equipment is made of fine red copper or stainless steel. It is gorgeous and elegant.

B, can be brewed black beer beer beer yellow red fruit beer and other beer beverage kbac.

C is simple, flexible, low power consumption and small footprint.

D, the production environment, sanitation, clean, pollution-free, wine overflowing.

E has a high degree of automation and can produce good beer even if it's not a brewing specialty.

F, less investment, large profits, recoverable investment within a year.

Five. Market analysis:

1, small investment and quick results

Small beer brewing equipment, to meet the production requirements, the general investment can be recovered in the year, and can make a profit, and large beer factory tens of millions of dollars, hundreds of millions of investment, recycling cycle long, low profits.

2, unique technology, high quality beer

As the micro equipment on-site brewing, on-site consumption, can be set free of miscellaneous bacteria infection system brewing, without filtration, without high temperature treatment, without any additives unique process and the real melting of whole malt brewing in one. Therefore, of course, the taste is more pure, fresher, more nutritious, more hygienic and reliable. In particular, the production process without any additives, is any bottled beer (including pure draft beer) can not be compared with it, is the real flavor, all natural beer, can be called beer boutique in the boutique.

3, four seasons production and variety of complete

Due to the small size, flexible production, not only can produce unique yellow fresh beer, and can produce black beer, wheat beer, beer, beer, red green low fruit and winter warm beer, beer and other characteristics of Hot pot of beer at the same time.

4, convenient sales and good market

As the output is small, the hotel, hotels, shopping malls, entertainment centers and other self-sufficiency based, easy to sell, if there is excess, you can also go to the surrounding Hotel, home wine cans or beer bucket sales, the market is vast.

5, unique, improve the hotel's core competitiveness

A beer, is equal to the hotel has its own brewery and its own brand of beer, is one of the important facilities in the hotel have a unique style, so will enhance the visibility of the hotel, enhance the competitive strength, planning and publicity is more conducive to advertising and image, more conducive to China's catering industry with the world. As we all know, beer is fresher and better to drink, so only micro beer is the freshest beer in the hotel.

| Milling System | Capacity | 300L |

| Index | Stainless Steel Outshell,Double Roller,Alloy rollers |

| Brewhouse | Material | SUS304/316 Or red copper |

| Capacity | 3bbl |

| Configuration | Two Vessel: Mash/Lauter tank, Kettle Whirlpool tank |

| Combined Three Vessel:Mash/Lauter/Whirlpool tank, Kettle |

| Three Vessel if cutomer's demand |

| Heat method | Electric |

| Steam heating via Electric, LPG,Natural Gas and so on |

| Thickness | Interior thickness: 3.0mm; |

| Exterior 2.0mm; |

| Welding | 100% TIG welding with pure argon gas shield |

| Interior Finish | Overall polishing to 0.4-0.6 μm without dead corner |

| False Bottom | Laser cutting V-wire False Bottom |

| Sieve Plate | 0.7 mm Strip-shaped holes, SUS304 material |

| Grain rake | With fixed speed motor and turbine reducer |

| Temperature sensor | PT100 |

| Insulation | Polyurethane-thickness:80mm. |

| Sparging ring | Easyclean and detachable |

| Spraying ball | 360° coverage CIP Spraying ball |

| Fermenter | Material | SUS304 316 Or red copper |

| Volume | 6bbl,3bbl |

| Thickness | Interior thickness: 3.0mm; |

| Exterior 2.0mm; |

| Welding | 100% TIG welding with pure argon gas shield |

| Interior Finish | Overall polishing to 0.4-0.6 μm without dead corner |

| Temperature sensor | PT100 |

| Cooling media | Glycol water or alcohol water. |

| Cooling jacket | Dimpled plate on cone and body |

| Insulation | Polyurethane-thickness:80mm. |

| Spraying ball | 360° coverage CIP Spraying ball |

| Pressure Test | Stringent tank and Jacket leakage test by water and pressured gas

Test Pressure:0.3 Mpa.Three times before shipment |

| Discharge | Tri clamp discharge arm with butterfly valve |

Glycol

Cooling System | Glycol water Tank | 8BBL |

| Chiller | 3HP |

| CIP System | Two tanks with trolley | 50L |

| Control System | Digital panel or PLC control |

|

Brewhouse System:

Cominated 3 vessles

Two vessles brewhouse (red copper)

Fermentation System:

Top manhole fermenter

Side manhole fermenter