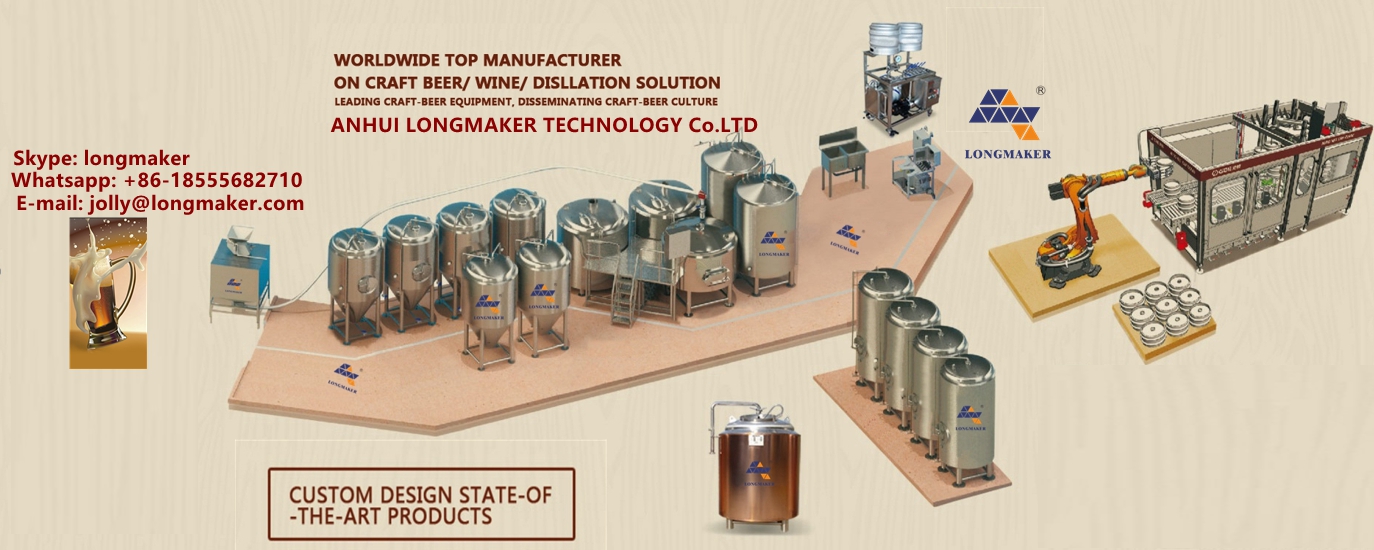

TurnKey brewery Project with high level technology.

2. Custom made for any size.

3. International standard stainless steel 304,316 and red copper material.

4. Seamless Welding&8 times Inner polishing.

5. Advanced produce equipment.

6. Leading manufacturer of craft brewing equipment in China.

| DailyOutput | 100L | 200L | 300L | 500L | 600L | 800L | 1000L | 2000L | 3000L | 5000L |

| Unit Type | HL100 | HL200 | HL300 | HL500 | HL600 | HL800 | HL1000 | HL2000 | HL3000 | HL5000 |

| FloorSpace | 15m² | 20m² | 25m² | 45m² | 55 m² | 70m² | 80m² | 120m² | 150m² | 250m² |

| Power | 8KW | 12KW | 20KW | 35KW | 35/15KW | 35/15KW | 35/15KW | 65/15KW | 65/15KW | 65/15KW |

| Electricity | 3P 380V(220V, 110V, 415V...) 50(60)HZ; 1P 220V(120V,110V,240V...) 50(60)HZ |

Beer Brewing Equipment

Our product includes a variety of large, medium and small brewery equipment, hotel, bar home-brewed beer equipment, teaching experiment etc. And could be used to brew various types of wine, beer, barley-bree (whisky) brandy. We supply brewing of main and auxiliary raw material, technical training, secondary equipment and control equipment, of course, can customize according to customer required special specifications design, production, installation of equipment and other products.

Brew house System

The brew house system could be included two-vessels brew house, three-vessels brew house and four-vessels brew house. Two-vessels brew house includes mash/lauter tun and kettle/whirlpool tank. Three-vessels includes mash tank, lauter tun and kettle/whirlpool tank. Four-vessels includes mash tank, lauter tun, boiling kettle and whirlpool tank. The capacity is bigger, the vessels is more. It is just in order to reduce the brewing time, improve the working efficiency.

PRODUCT FEATURES:

Our Fermentation tanks tun available from 100L to 20000L and average 25% Head Space.

All tanks have a Dish top,

Cylinder body & 60/70° Cone Bottom.

Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

All tanks use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

We can customize fabricate any tank to meet your brewery's space and height restrictions.

Brewing is a complex process that combines technology, technology, and art. It is rooted in the strong historical background and cultural tradition, and with the talent of bringing forth new products, it can often pave the way for the application of the most advanced technology.

1. Introduction

Our products have been exported to all of the world, such as USA, Canada, Mexico, Peru, Costa Rica, Chile, France, Belgium, UK, Singapore, Korea, Australia etc. So we are confident to meet your needs. Now, please follow me to see more details about our products.:)

The 50L beer brewing equipment is widely used in pub, laboratory, home. The configuration is flexible depending on different working efficiency:

Brewhouse combination is flexible according to your needs and daily work shift. In general, there is just one main tank, mash,lauter, kettle and whirlpool function all in this tun, heating is electric.

Fermenter quantity will depend on beer daily output and beer fermentation cycle.

Cooling system including glycol water tank, pump and chiller. The big cooling capacity used in heat exchanger, for cooling wort.

Control system we have 2 type, PLC control and Digital control system.

3. Guarantee & After Sales Service:

| 5 years warranty | 24 hours service |

| Guide and free installation | Beer recipes |

| Spare parts | Quality guarantee |

| 3D drawing and details drawing | Manual operate book |

4.Production pictures

This is our 500L-1000L beer brewing equipment to Mexico, hope you like it.

for packing and shipping

For the packing, we always do plywood wooden case for the 50L brewery equipment. It is very safe for machine, a void friction. Also it just take 4M3 space, very easy to move it to your place.

1. Can your beer brewing equipment make both lager and ale?

A: Yes, our beer brewing equipment can make both lager and ale.

2. How to achieve temperature control?

A: The PLC or digital dispalyer could control the temperature by connecting with the PT 100 sensor. The brewing tanks with rock wool to keep warm, the fermenters and bright beer tank with PU as cooling jacket to keep cool.

3. What type of control system?

A: Our control system is PLC control, also pass the CE.

4. What is best suitable place to it?

A: As you can it from our pictures, our 50L system take a very small space. it is very good for home and pub, also fit foir test machine. If you put it in pub, make a beautful waiter push it to sell beer to cstomer, you will get more and more clients. Fighting!

5. Do you have beer receipt? And can you teach us how you brewing beer? Do you know how to install it?

Want know the answer?Please contact us

FAQ

1.Q: Could your equipment brew both Ale and Lager?

A: Yes, all kind of beer could be brewed in our equipment.

2.Q: I'm not a brewer, could I brew beer with your equipment?

A: Yes, we have the professional brewer to teach you how to brew, and we could give you the formulation after order placed.

3.Q: How long it will take to finish the production?

A: It depends on the capacity. Usually it'll need 30 to 50 working days for the production and Pressure test.

4.Q: How long is the warranty?

A: Three year's warranty for tanks and one year's warranty for the accessories. All life service.

5 Q: How about the installation? Could your engineer go abroad for after-sale installation?

A: Of course. ...Inquiry for getting more clear answer .

Five. Market analysis:

1, small investment and quick results

Small beer brewing equipment, to meet the production requirements, the general investment can be recovered in the year, and can make a profit, and large beer factory tens of millions of dollars, hundreds of millions of investment, recycling cycle long, low profits.

2, unique technology, high quality beer

As the micro equipment on-site brewing, on-site consumption, can be set free of miscellaneous bacteria infection system brewing, without filtration, without high temperature treatment, without any additives unique process and the real melting of whole malt brewing in one. Therefore, of course, the taste is more pure, fresher, more nutritious, more hygienic and reliable. In particular, the production process without any additives, is any bottled beer (including pure draft beer) can not be compared with it, is the real flavor, all natural beer, can be called beer boutique in the boutique.

3, four seasons production and variety of complete

Due to the small size, flexible production, not only can produce unique yellow fresh beer, and can produce black beer, wheat beer, beer, beer, red green low fruit and winter warm beer, beer and other characteristics of Hot pot of beer at the same time.

4, convenient sales and good market

As the output is small, the hotel, hotels, shopping malls, entertainment centers and other self-sufficiency based, easy to sell, if there is excess, you can also go to the surrounding Hotel, home wine cans or beer bucket sales, the market is vast.

5, unique, improve the hotel's core competitiveness

A beer, is equal to the hotel has its own brewery and its own brand of beer, is one of the important facilities in the hotel have a unique style, so will enhance the visibility of the hotel, enhance the competitive strength, planning and publicity is more conducive to advertising and image, more conducive to China's catering industry with the world. As we all know, beer is fresher and better to drink, so only micro beer is the freshest beer in the hotel.

How to build your own micro brewery

-----Micro brewery system design

Part 1:

Make an initial communication with your brewery system supplier

You must collect some necessary information and make a general plan of your microbrewery business. Then you are able to talk about your idea with your micro brewery equipment suppliers. They will feedback you if your idea is workable. Most of the equipment suppliers like us have a standard configuration of the whole beer system which they think is reasonable and common. You must get a professional and detailed equipment list. It will very helpful for you to get full information of your brewing equipments. Of course, this equipment list just give you a top view of the whole system. There should be something which is not suitable or customerized for you. So we should talk more.

Part 2:

Work out what you want for your own micro brewery equipment

Pick up the items from the equipment description which you are going to make special design. Make a list of them and show your own idea in the list. For example, the micro brewery brewhouse system in the standard equipment list is steam heated which you may like directly fire. The steam boiler is a problem in a lot of area because it is too expensive and complicate installation. Tell to the representive of the beer equipment supplier. They will design it into directly fired brewhouse and show you their design. Another concern such as the cladding material is customerized too. You may like a copper cladding to make your brewpub more luxury while the list is with stainless steel. One by one, you will figure out a customerized equipment list according to your idea. Please remember, only spend time on the equipment list which you think everything is clear and exact. An upside-down or inaccurate brewery equipment list only waste your time and bring you to a big confusion.

Part 3:

Make sure your brewery system is designed by professional technician.

Nowadays, most of the communication happens by email. What you say about the beer equipment design perhaps or sure is another understanding if the communication is only by 'words'. What is more, doing business with Chinese companies always have some trouble with language and value philosophies. Most beer equipment designers will supply some technical drawings for your system, such as brewing tanks drawing which show you every parts of the tank, the mashing flow chart which show you the brewhouse pipe connections, the floor plan which show you the system dimensiono in your brewery and even some loading drawing to save you money for sea transportation. If your craft brewing equipment is very special and you don't know 2D drawings very well, some suppliers may design the 3D drawing to show the brewery design visually. Of course, it will spend a lot time to design 3D drawing for the technicans. Things are better if you have chance to visit your suppliers and talk your idea face to face. Or please do spend more time to make sure the brewery machine design is what you want.