Sammary:

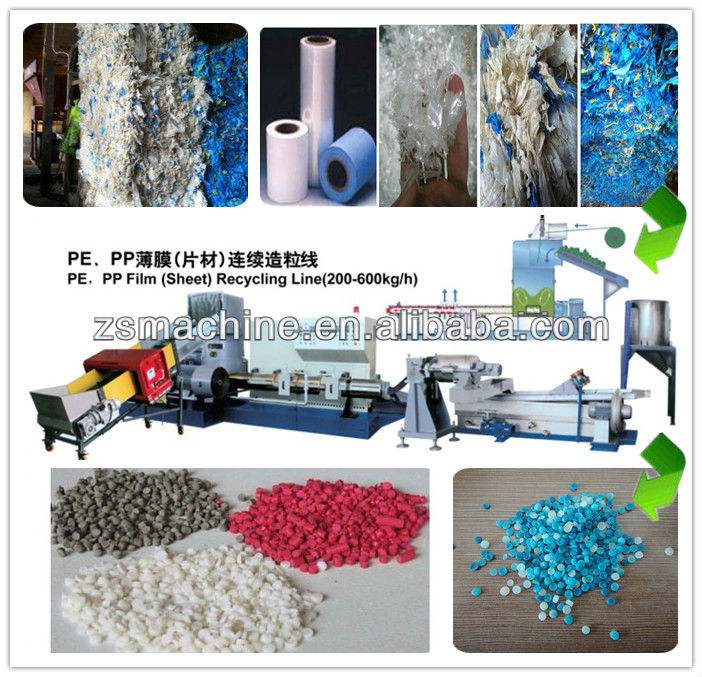

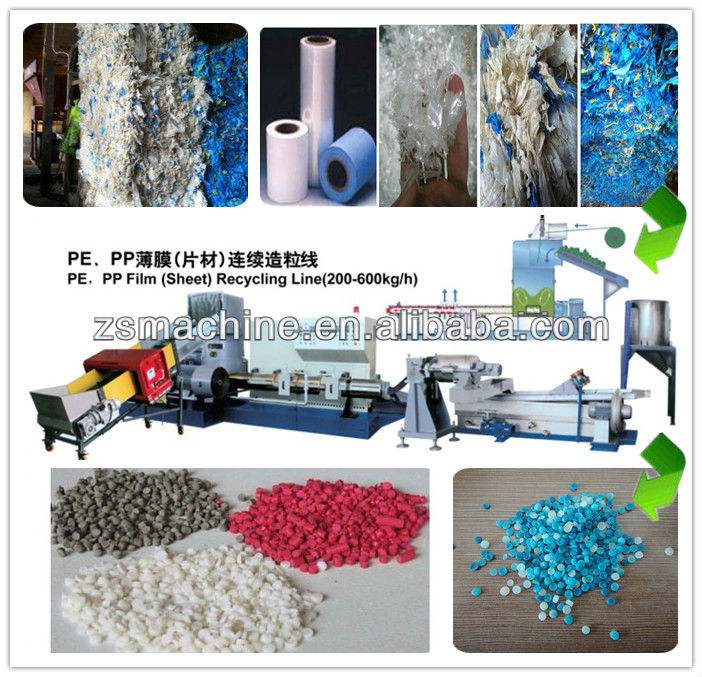

Plastic pelletiziing machines are adopt for producting pellets such as ,PE,PS,ABS,PA,PVC,PC,POM,

EVA,PET,PMMA ect with specific designs on screws and with different configurations.High torque gear box could keep the machines working steady with low noise. Screws and barrels after specific treatment processing which has the features of wear resisting, good mixing performnce,high ouput capacty. Vacuum exhaust or ordinary air vent design could discharge water and ar n material to get high quatlity pellets

What we can do with HDPE Pelletizing machine ?

The Plastic Granulating Machine is used for plastic film, wire/cables, sheet( thickness is less than 0.5mm),belt,shopping bag or woven bags and so on, It has the features of nvel design, compact structure, reasonable layout,stable,facilitating and maintenance and debugging,Low noise, Low-power consumption and high output.

a. Capacity:100-700kg/h (according to different materials)

b. The recycling material thickness requirement: <= 0.5mm

c. With two types of cutting way: Water ring(roop)/die head cutting or noodle cutting for choice.

We can meet your different demands for the shape of granules.

d. Non-stop hydraulic screen changer will running when extruding.

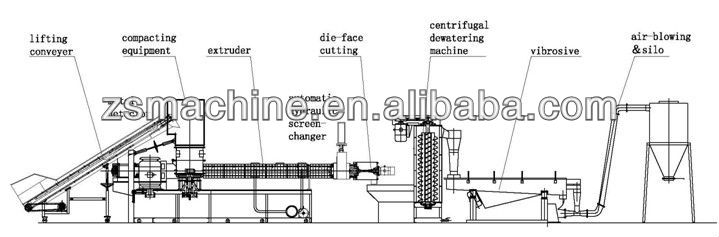

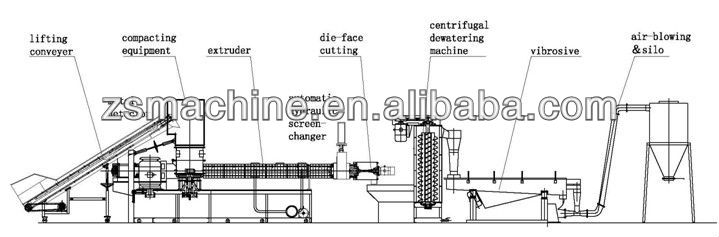

Flow chart design:

Componentsfor The PP/PE HDPE Pelletizing machine :

Conveyor —agglomerator(compactor)—extruder—die(mould)—water ring cutting system

—high speed hydraulic screen changer — dewater machine—air blowing storage silo etc.

Metal detector could be chosen as optional on the First conveyor.

Specification for different models:

Model | Srew diameter | L/D ratio | Power(about) | capcaity (PE) | capacity (PP) |

ZS-80 | 80MM | 33:1 | 140KW | 120-180KG/H | 100-160KG/H |

ZS-100 | 100MM | (28~36):1 | 200KW | 220-300KG/H | 180-240KG/H |

ZS-120 | 120MM | (28~36):1 | 280KW | 420-500KG/H | 280-380KG/H |

ZS-160 | 160MM | (28~36):1 | 330KW | 550-700KG/H | 380-560KG/H |

Photo performance:

CE certificate:

Loading time:

Where we produce our machines?