80×156 PVC (wood-plastic composites) foam board Production Line

Major features:

Smooth surface with high surface hardness

Excellent performance in sound insulation and absorption, and thermal insulation

High flame retardation ensures safe operation

The sound weather resistance makes the products highly resistive to color-fading and aging

Low density and weight enable easy storage and transportation

Even the common wood processing devices can be used

Drilling, sawing, pegging, shaping and pasting can be applied to our products

Applicable to thermal forming, bending and folding

Can be welded under normal procedures or can be adhered to other PVC materials

Applications :

Our products can be used as wall and internal decoration plates for carriages, ceilings, floors, walls and internal decorations of ships, buses and trains in traffic and transportation industry.

They can also be used as the plates for the exterior walls of buildings, internal decorations and cabinets, as partitions for residential apartments, offices and public facilities, as decoration brackets for commercial purpose, and as plates for clean rooms, ceilings and home furnishing. With printing, coating and hot-pressing equipment, our products can be used to various wood-like products.

Parameters and merits :

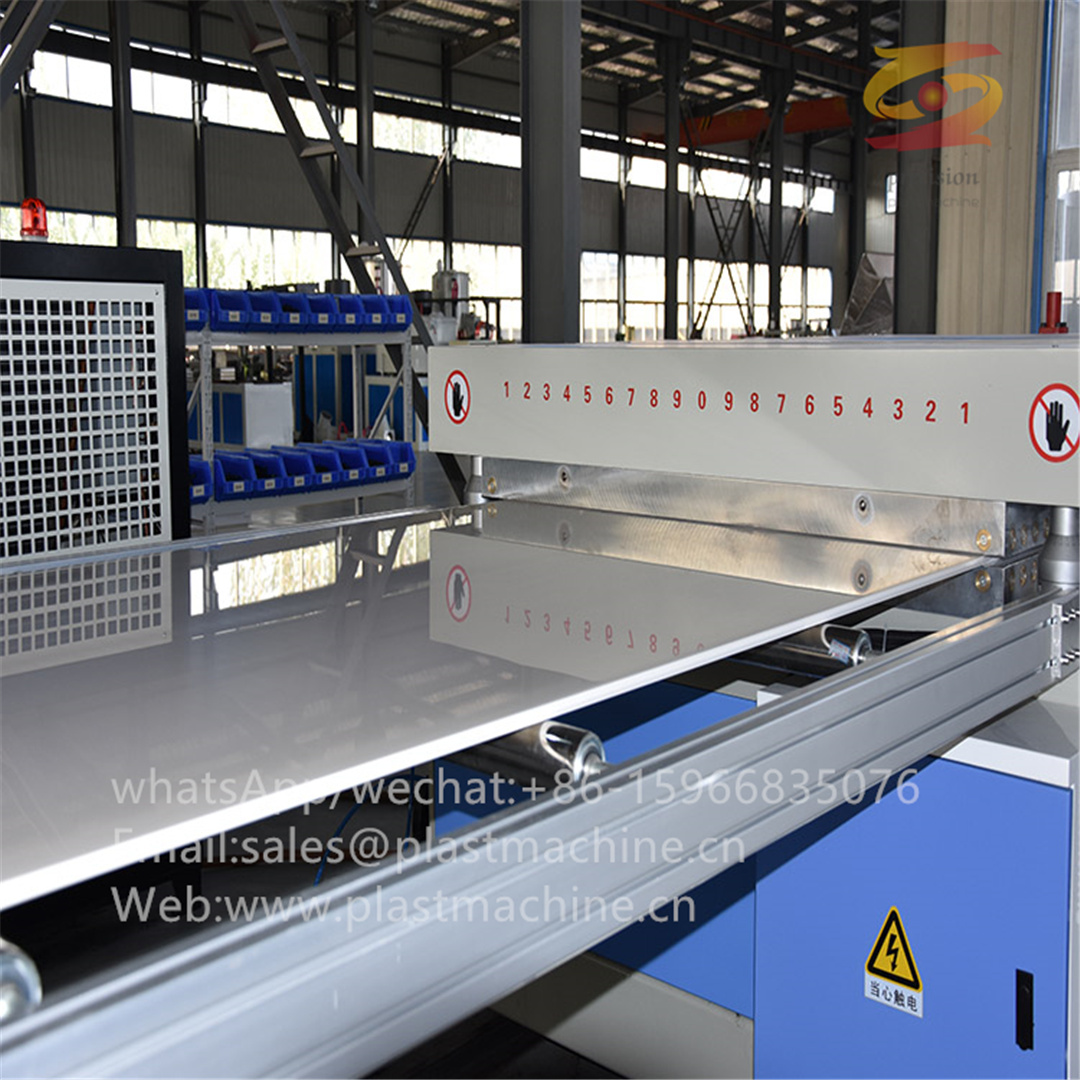

This production line composes of conical twin screw extruder, plate dies, forming table, hauler and cutter. The extruder adopts the specially designed screws, improving the integration and plasticizing between PVC and wood powders, and enhances the rigidity of products significantly. The products enjoy a promising future for applications.

Product width 1, 220mm

Product thickness 3-30mm

Extruder model SJSZ-80×156

Maximum extrusion output 400Kg/h

Main motor power 75KW

Dimension L × W × H =20m×2m×2.6m

Weight 25T

Installed capacity 150KW/h