10T/D Wheat flour-milling machine Flour production line

Flour mill

1. Technological Index

<1>main technical parameter

1. model:6FTBP-40

2. cleaning technology:3 times of sifting, 2 scouring, 2 destoning, 1 dampening, 4 magnetic separation and 2 winnowing.

3. Flour milling technology: drum sieve grading, flat sieve extracting, 4 grinders for bran, 3 for kernel and 1 for residue ( or 3 for bran, 4 for kernel and 1 for residue).

4. Total power: 90kw

5. Weight: approximately 14t

6. Container: 1×40 feet

7. Dimension of the workshop(length*width*height)

30×8×7.5(m).

8. Operators: 4 per shift

<2>main index

1. yield:40tpd

2. Flour quality:up to GB1355

3. Flour extract(medium class wheat): special second class flour 70-74%,special first class flour 60-65%.

4. Power consumption per ton approximately 60kwh.

2. Technological Flow Chart

The whole line is divided into cleaning workshop (drawing1) and flour milling workshop (drawing 2.3)

3. Parameter of Main Equipments

Vibrating sifter:

FEATURES

★Small size, low weight, high output, excellent performance;

★Scientific structure, stable performance, low noise, high efficiency low energy consumption;

★Great sanitation thanks to enclosed structure;

★Easy operation and maintenance due to compact design;

★Excellent design provides flexibility with regard to existing spatial conditions.

FUNCTIONAL DESCRIPTION

The machine is employed for cleaning and classification in flour milling, oil expression, rice milling, animal feed, food processing and chemical industry or in grain storage facilities (silos). With its different specification of sieve desks, it can remove coarse and fine impurities from wheat, corn, rice, oilseed etc, which makes it ideal equipment for small and medium-sized food processing plants.

TECHNICAL PARAMETER

| Type | Yield

(T/H) | Power

(KW) | Vibrating

Frequency

(R/MIN) | Vibrating

Direction

Angle (°) | Wind

(M³/MIN) | Weight

(KG) | Dimensions

(MM) |

| TQLZ80/150 | 4-6T | 2*0.25 | 920-950 | 0-45 | 50 | 520 | 2500*1300*1500 |

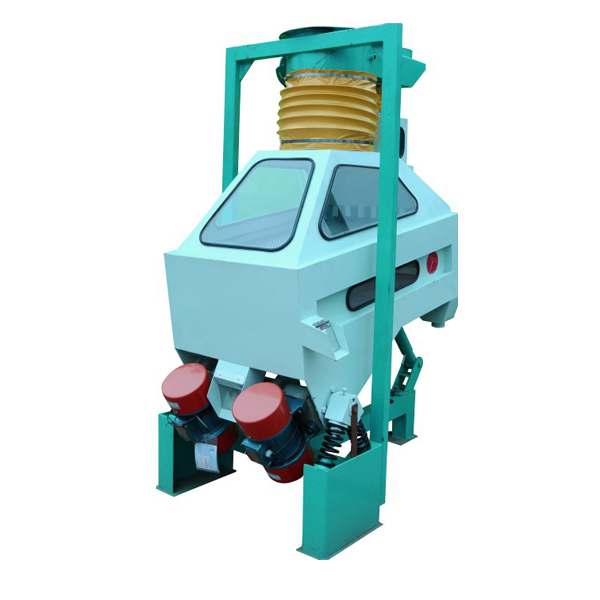

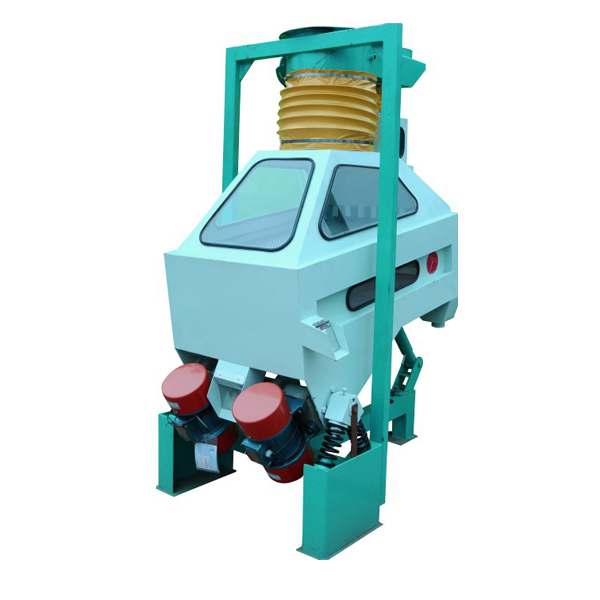

Proportion Classifying stoning machine:

FEATURES

★Grades the raw materials and removes the stones at the same time;

★Reasonable structure, small footprint, light and easy operation;

★High yield, smooth performance, flexible and adjustable;

★Enclosed structure, dust free, low noise;

★High quality thanks to advanced design concept and much years manufacturing experience.

FUNCTIONAL DESCRIPTION

TQSF series specific gravity de-stoner is newly designed high efficient equipment specially for the cleaning of corn (maize). The equipment adopts the most advanced "Reverse cleaning theory", it is employed for the efficient removal of high-density matter and low-density impurities from the grain stream which provides additional protection to downstream process, and wear is reduced significantly. It is a wonderful choice for grain intensive processing plants both in china and overseas.

TECHNICAL PARAMETER

| Model | Yield

(T/H) | Frequency

(R/MIN) | Sieve Dip

Angle (º) | Aspirating

Capacity

(M3/MIN) | Power

(KW) | Weight

(KG) | Dimension

(MM) |

| TQSF-80 | 3-4 | 940 | 5-9 | 145 | 0.25x2 | 340 | 1300*916*1800 |

TQLMZ Plansifter:

TQLMZ series plansifter is the equipment to clear the medium, large or small impurities in the grains. It is widely used in grain, feed, food, chemicals and brewing industry.

TQLMZ series plansifter is the equipment to clear the medium, large or small impurities in the grains. It is widely used in grain, feed, food, chemicals and brewing industry.

According to the material separation requirements, this screen can adjust the rotation speed and the overlapping amount of the eccentric blocks. The screen body can have three running tracks with the alternating motion: the front part is a circle, the middle part is an oval, and the tail part is a straight line. Practice has proved that, various motion modes can clean the impurities more quickly for different grains under complicated impurities circumstances. Separate the ghost and light impurities from the material by vertical suction segregation method.

Main technical parameter:

| Project | Unit | TQLMZ80 | TQLMZ100 | TQLMZ125 | TQLMZ 150 |

| Handling capacity | wheat | t/h | 4-6 | 6-8 | 8-12 | 10-15 |

| Screen width size | mm | 800 | 1000 | 1250 | 1500 |

| Rotation speed | r/min | 300 |

| Screen leaning angle | . | Upper layer sifter 7.,under layer sifter 8. |

| Motive power | kw | 0.55 | 0.55 | 0.75 | 1.1 |

| Air volume | m3/min | 60 | 80 | 90 | 100 |

| weight | Kg | 750 | 800 | 850 | 900 |

| dimension(length×width×height) | mm | 2193×1194×1374 | 2193×1394×2066 | 2193×1644×2129 | 2193×1894×2191 |

|

|

|

|

|

|

|

Stone removing and wheat washing drying machine

Wheat washing machine's box adopts steel plate to weld. Inside of it have two pairs of spiral conveyer. ( Figure 7) To make the stone passes, the wheat spiral conveyer adopts oar type vane. When the wheat drops in the stirring water, it can not sink but keeps suspending. Then it is conveyed by the spiral conveyer for drying. The stone spiral conveyer adopts cover type of vane to send the stone to the opposite direction. When the sandstone drops in the sand bucket on the tail part of the tank-washer, it will be cleared out by the workers regularly. The stone removing basic principle is on the basis of different proportion of the wheat and the side by side stone. It uses the horizontal spiral conveyer which has certain speed and pushes the wheat which sinks slowly in the water from one end to another end. The stone can sink quickly. So the stone leaves the spiral conveyer gradually and sink into another spiral conveyer. It is sent out from the opposite direction so as to realize the real goal of the wheat and the stone.