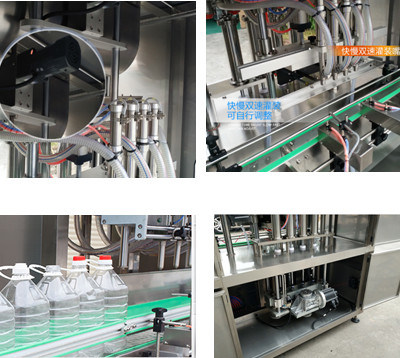

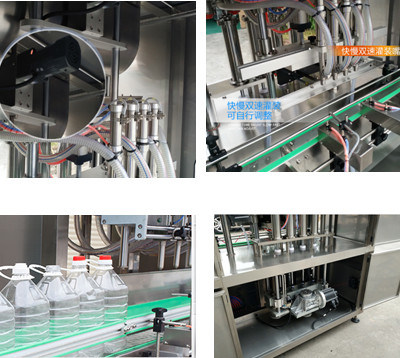

Equipment introduction: 1, using high precision flowmeter with the high precision pulse coder, Taiwan delta programmable controller PLC and Taiwan weinview touch screen terminal, the filling process is accurate and reliable; 2, the Chinese color man‐machine interface, set the parameters of the device is intuitive, simple; 3, the filling head is equipped with an independent vacuum suction device; 4, fast and slow filling, filling process does not bubble, material does not overflow; 5, electrical accessories with well‐known brands, stable operation, durable; 6, the conveyor belt can be used to separate the operation of double track, filling, gland separate, high efficiency;

Technical parameters:

1, equipment type: TGM‐LZ4

2, equipment power: about 2.5‐3.0Kw

3, working voltage: AC380V/50Hz

4, filling capacity range: 500ml‐5L

5, filling efficiency: 490‐860 bottles / hour (5L)

6, filling accuracy: less than 0.5‐1%ml (5L)

7, the whole machine weight: about 650Kg

8, compatible bottle height range: 260‐350mm

9, compatible bottle width or diameter range: 60‐150mm or phi 60‐ Phi 150mm

10, compatible with the smallest bottle diameter (inner diameter): Phi 26mm (special diameter can be customized)

11, external dimensions: 1700*1300*2100mm (length * width * height)

12, work direction: left to right out or right into the left out (optional)