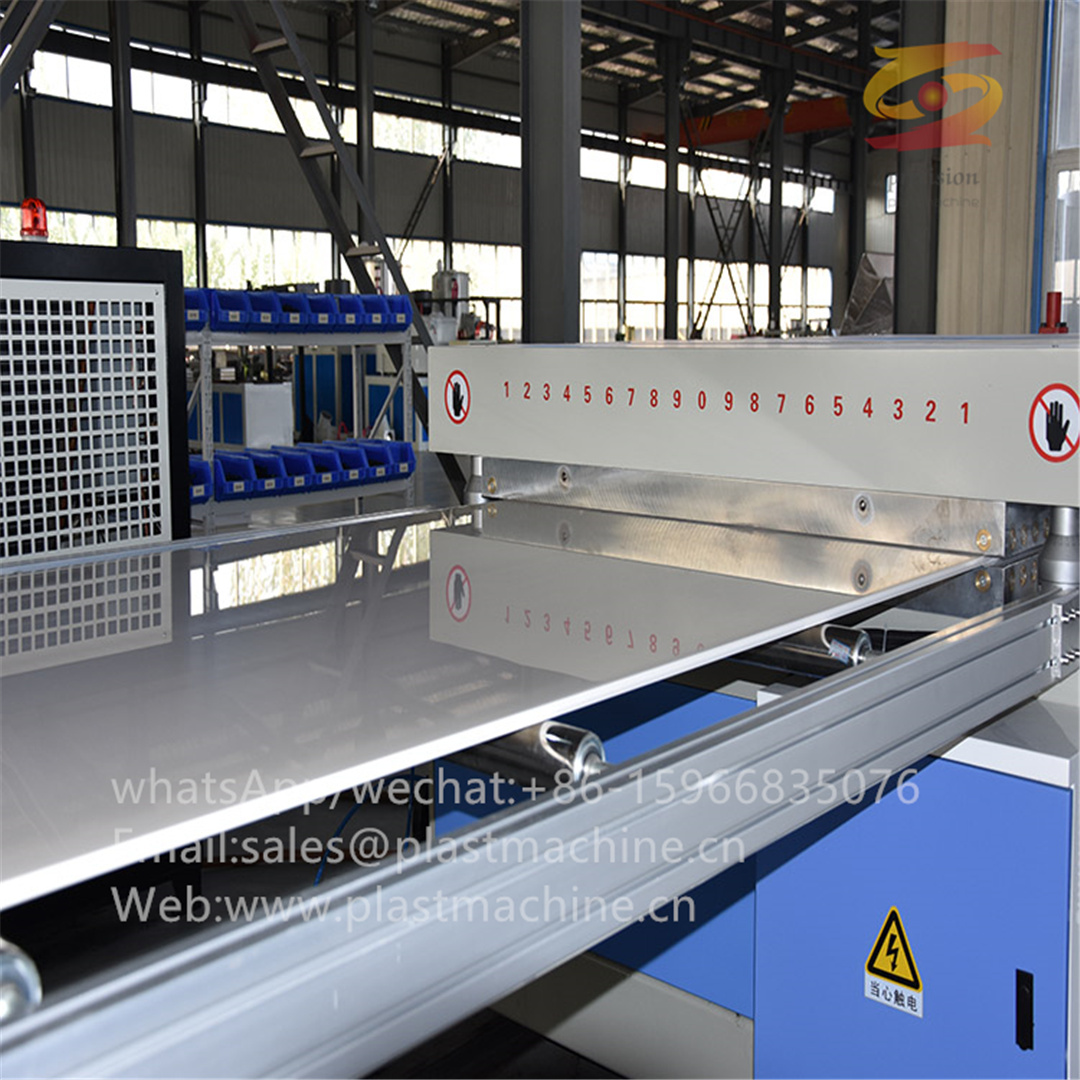

92×188 PVC (wood-plastic composites)crust foam board Production Line

PVC crust foam board making machine

1.Standard width:1220mm

2. Density: 0.45-0.8

3. anit-flame, anti-proof, anti-corrosive

Major features

PVC Crust Foam Board Extrusion Machine adopts Celuka foaming technology. Compared with PVC crust foam board, PVC crust foam board not only has much more smooth surface, but also the hardness is better. In addition, mechnics performance of Celuka foam board is better than that of free foaming board, PVC crust foam board extrusion line is composed of conical twin-screw extruder, die, vacuum calibration unit, haul-off unit and so on. Our company can provide the formula and all the processing techniques. The machine has the features of high output, stable extrusion, high foaming, smooth and wearable surface. By equipping with the printing machine, laminating machine or hot stamping machine, this machine can produce different kinds of artificial wood products, so that this machine has a very wide application range.

Eletrical Part of PVC Crust Foam Board Extrusion Machine

1. Main motor frequency controller: ABB

2. Temperature controller: OMRON or RKC

3. AC controller: Schneider or simens

4. Thermal overload relay: Schneider

Applications:

1. field: decration board, building templete, windows,furnitures, desk and chair

2. product: Real estate, Road bridge building, Coal channel clapboard, War industry, Ship, building, Trains.

3. decoration

4. green environment protection, waterproof, damp proof, anti-corrosion, rot-resistence, ametabolic and good fire-retardant

5. Dimension(L*W*H): 22m*2.5m*2.5m

6. main export place: north America,africa, Europe, southeast asia, south America, etc

8. Material is 100% recycled.

Parameters and merits of PVC (wood-plastic composites) Skinning Expansion Plate Production Line

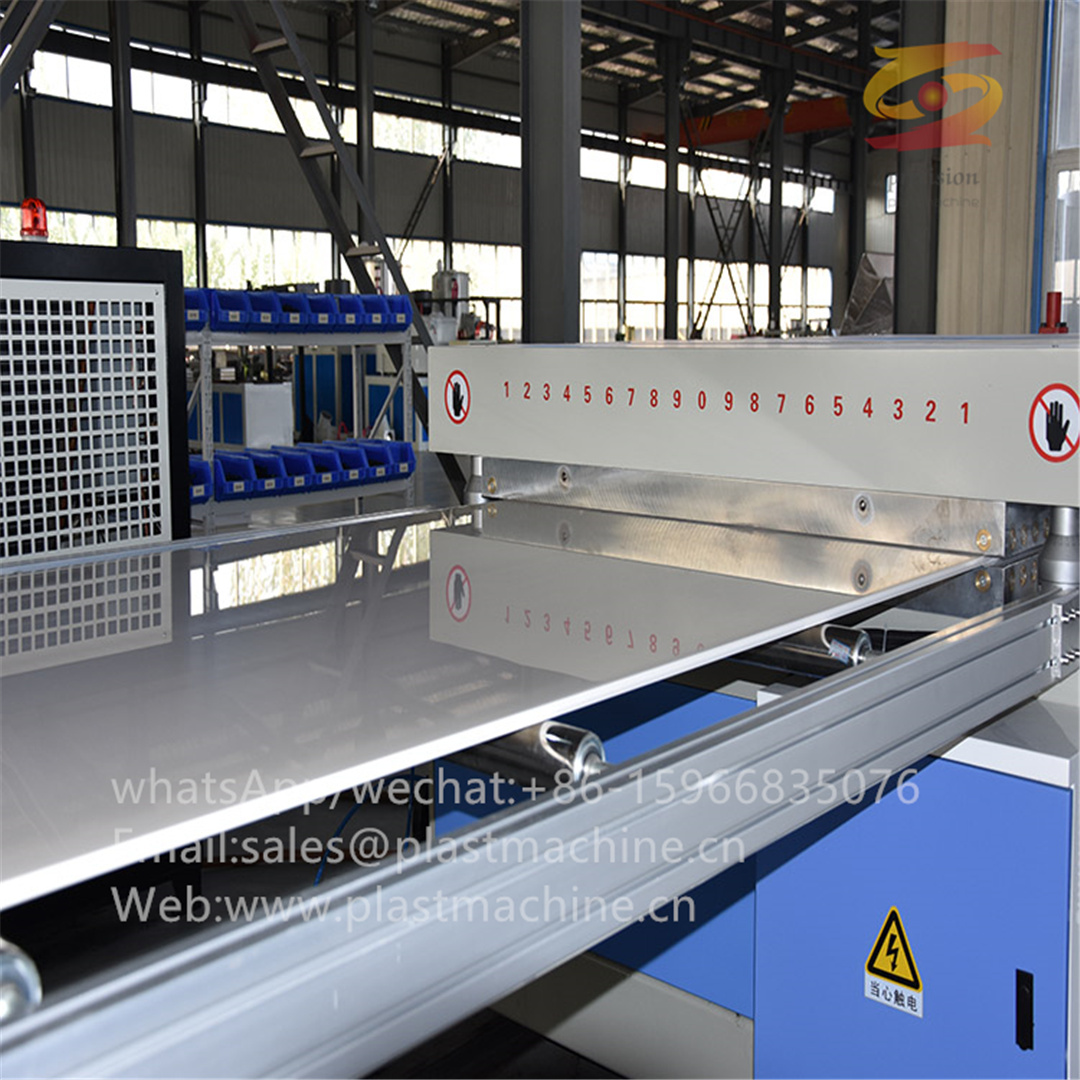

This production line composes of conical twin screw extruder, plate dies, forming table, hauler and cutter. The extruder adopts the specially designed screws, improving the integration and plasticizing between PVC and wood powders, and enhances the rigidity of products significantly. The products enjoy a promising future for applications.

Product width 1, 220mm

Product thickness 3-30mm

Extruder model SJSZ-92×188

Maximum extrusion output 800Kg/h

Main motor power 110KW

Dimension L × W × H =20m×2m×2.6m

Weight 30T

Installed capacity 210KW/h