HDPE Large Diameter Hollow Wall Winding Pipe Production Line

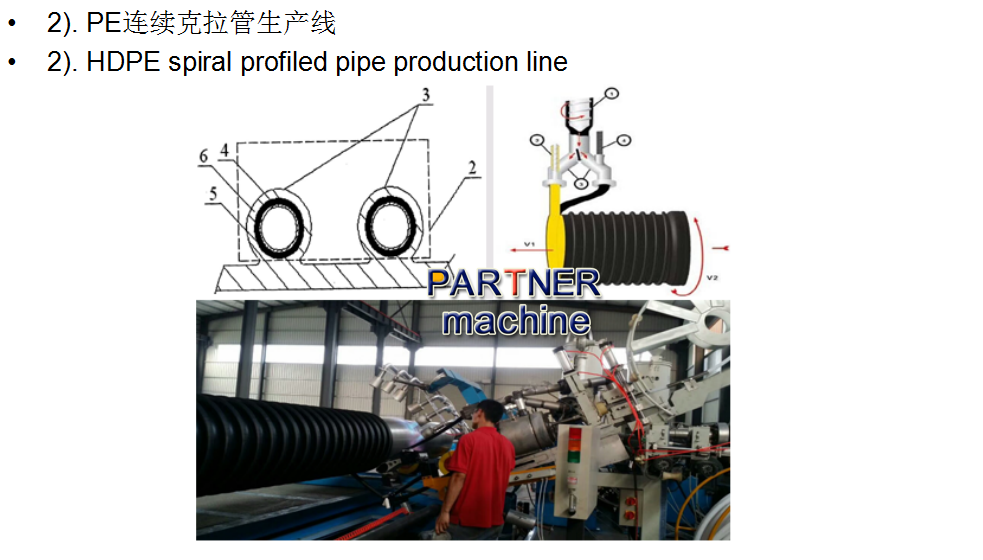

Brief introductions of HDPE twin-wall spiral pipe production line:

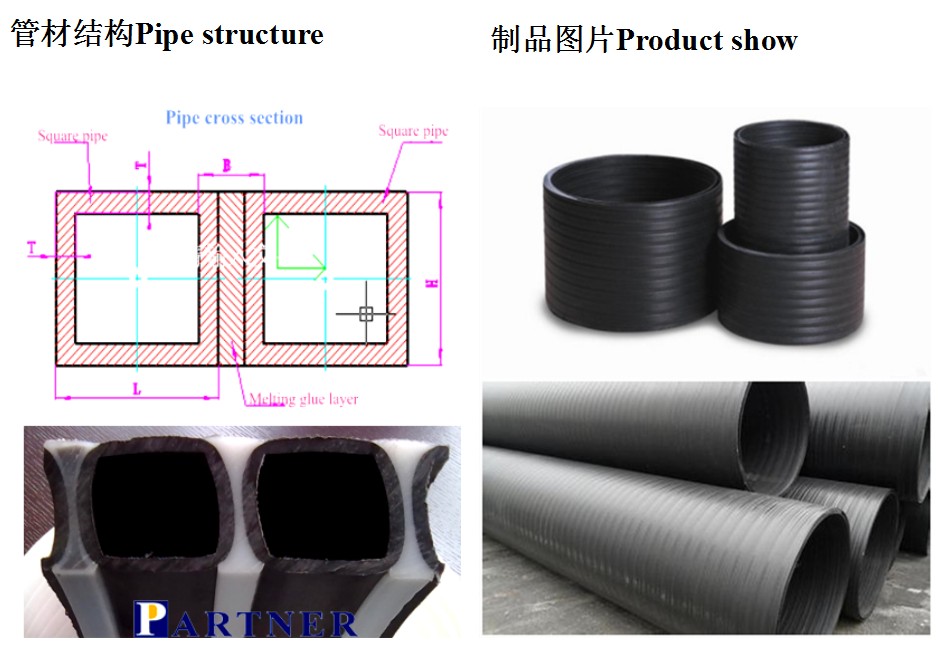

HDPE large diameter hollow wall pipe has been recognized as a substitute for cement pipes and cast iron pipes because it possesses superior advantages in water drainage and water sewage conduit. On this kind of plastic pipe line, We have the strongest technology advantages and rich experience .

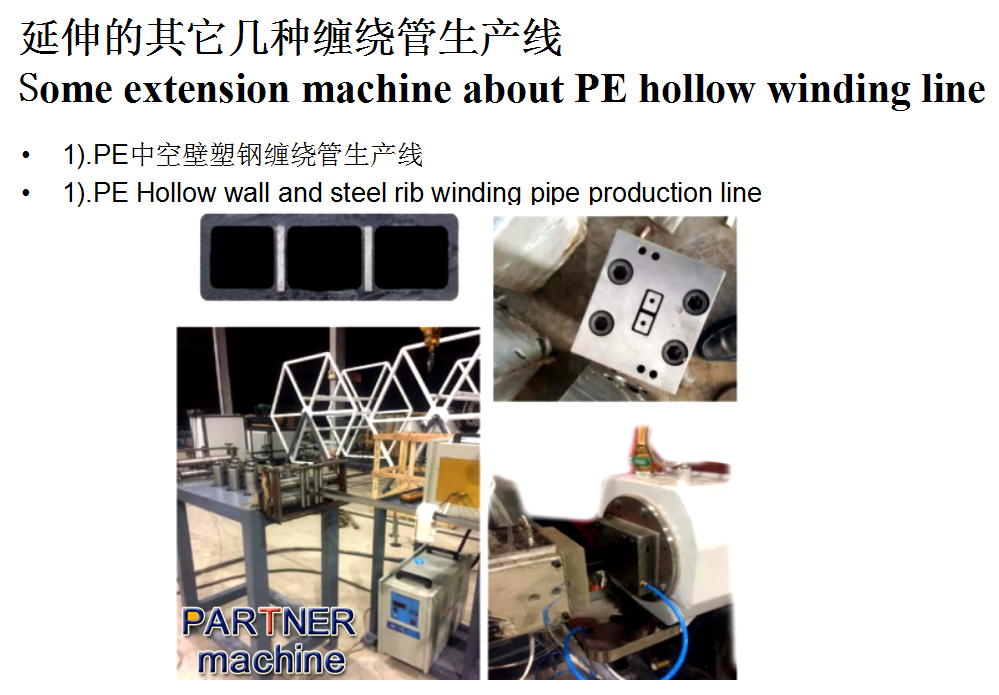

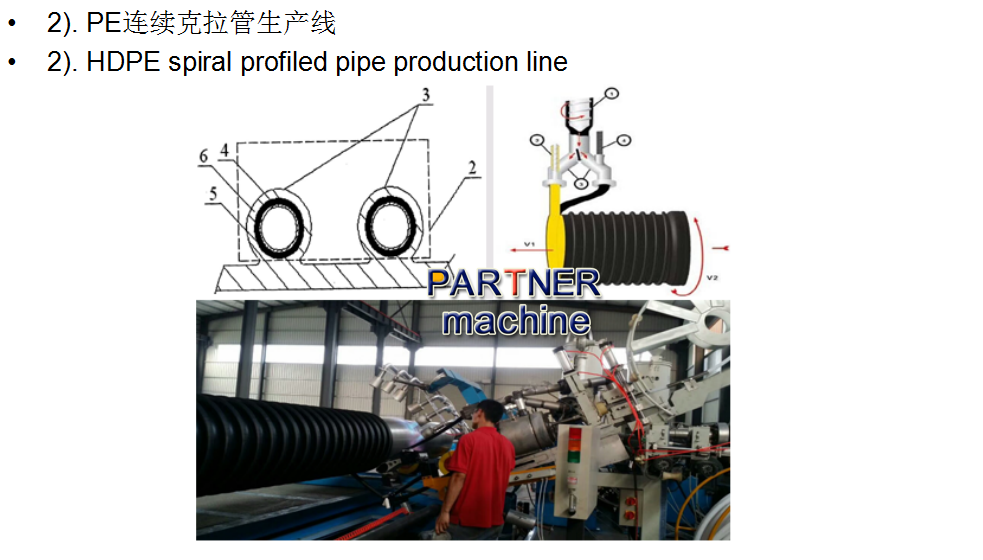

We are the earliest manufacturer of HDPE hollow winding pipe machines, has strong technological advantages and rich experience in installation and production, advanced design, high quality configuration is, reliably performance, long using life, the extrusion output is much higher than other suppliers in domestic. especially on large diameter pipe machine we rich experience in a confident manner.

One of our big cooperation customers, the largest pipe group POLYPLASTIC in Russia, their four extruder co-extrusion design for making in and out wound pipes and the machine got high praise from customer. Another one is POLYWORLD from Australia bought two lines on SKRG-1600 and SKRG-3000 for full size of pipes production, right now the machines work well and customer satisfy.

Main technical data of HDPE large diameter water drainage pipe production line:

Model | Pipe range(mm) | Extruder | Installed power (kw)

Load factor 50% | Max capacity

(kg/h) | Overall dimension

(L×W×H) |

|

Model | L/D | Power(kw) |

|

|

|

SKRG800 | 200-800 | SJ65×30

SJ55×30 | 30:1

30:1 | 55

37 | 140 | 200 | 18m×15m×3m |

SKRG1200 | 300-1200 | SJ90×30

SJ65×30 | 30:1

30:1 | 90

55 | 200 | 380 | 23m×15m×4m |

SKRG1600 | 800-1600 | SJ90×34

SJ65×30 | 34:1

30:1 | 110

55 | 240 | 580 | 25m×18m×6m |

SKRG2200 | 1200-2200 | SJ100×30

SJ65×34 | 30:1

34:1 | 160

75 | 300 | 650 | 30m×15m×7m |

SKRG3000 | 1800-3000 | SJ90×30

SJ120×30 | 30:1

30:1 | 90

200 | 400 | 850 | 32m×15m×8m |