1 Introduction

This machine is one of the traditional filling and capping equipment, advanced design, reasonable structure, can automatically complete filling and capping process, is suitable for the liquid ,such like perfume, syrup, tincture, alcohol,wine a variety of materials such as,and other functions. Can be used stand-alone, and also can be used for filling line. This machine completely accords with the new GMP requirements and EU certification.

2 Parts of filling machine

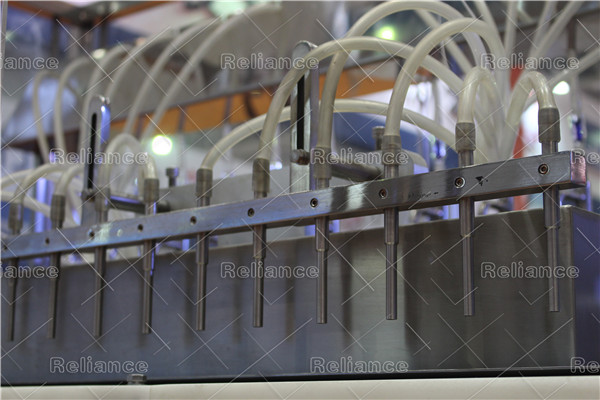

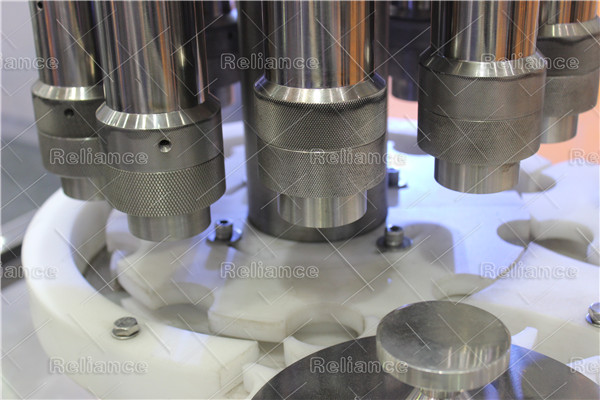

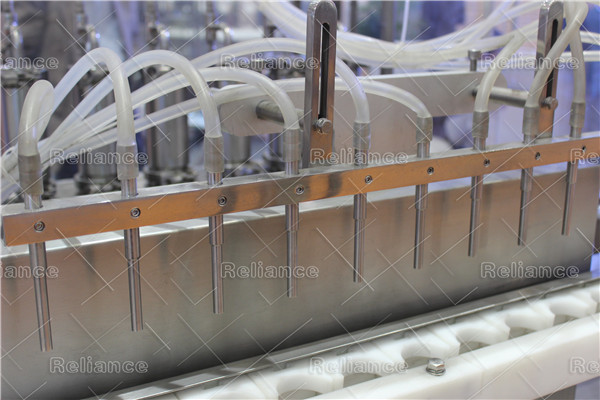

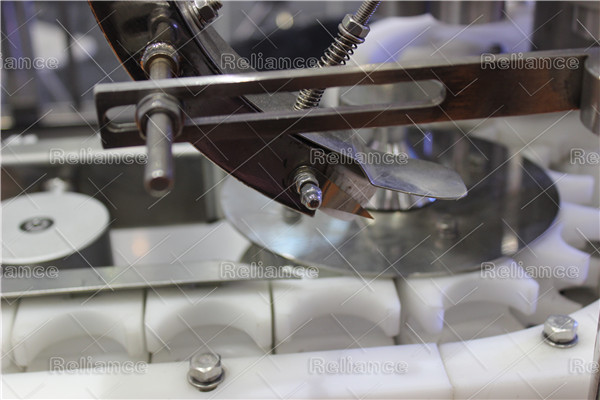

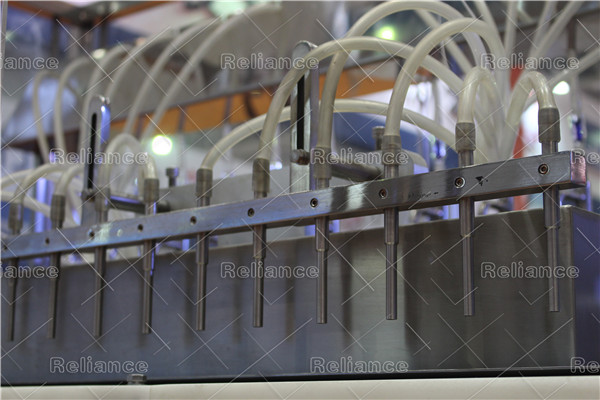

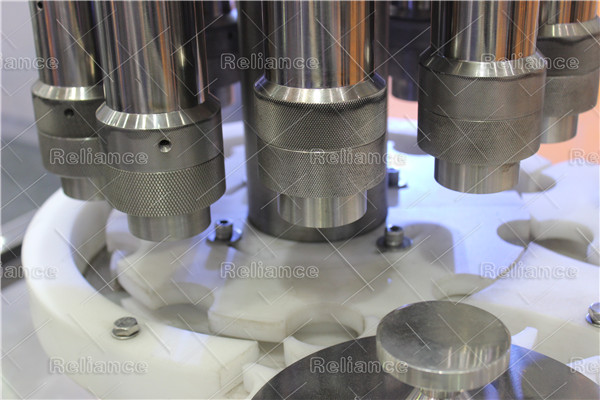

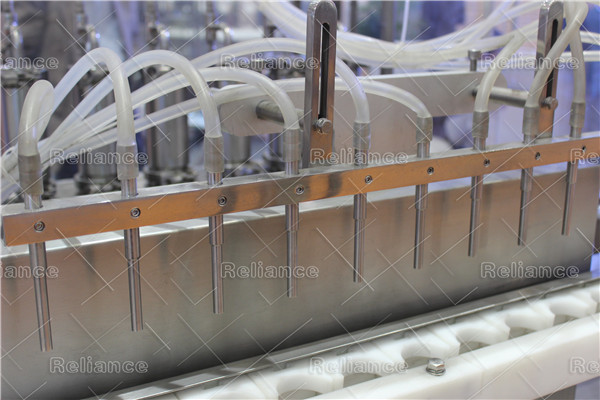

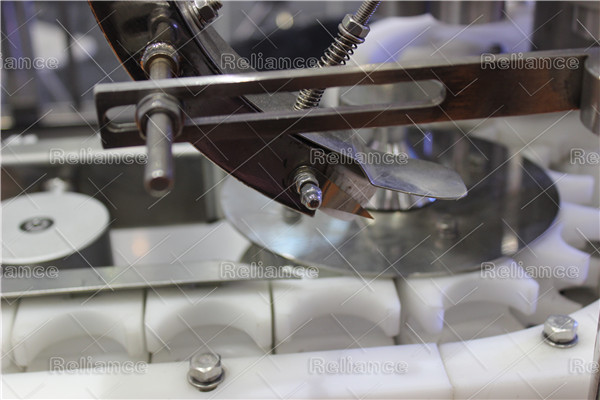

This filling machine including operating table, frame, capping head, hopper, track for cap, dosing pump, conveyor, star wheel and so on.

3 Working principle

Prepare enough bottles and caps and liquid, put the bulk caps into the hopper, and bottle will coming in to the filling station by the turn table through the conveyor, each 8 bottles will get into the filling station, after filling will get into the cap fitting and sealing station. 8 filling nuzzles will get down get into the bottle and filling inside to finish one time filling .

4 Characteristic

l The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

l Including feeder turntable,effective cost/space saving

l It has intuitive and convenient operation, measuring accurate, positioning precision

l Three knife centrifugal sealing, to ensure the sealing strong and beautiful

l Fully in accordance with the GMP standard production

l Optional Siemens Touch screen/PLC

5 Main Technical Parameters

Applied Bottle | 5-100ml |

Productive Capacity | 2400-3000 bottles/hour |

Filling Tolerance | 0-2% |

Qualified Stoppering | ≥99% |

Qualified cap putting | ≥99% |

Qualified capping | ≥99% |

Power Supply | 380V ,50HZ |

Power | 1.5KW |

Net Weight | 600KG |

Dimension | 2500(L)×1000(W)×1700(H)mm |