Introduction

liquid filling and capping machine is the main equipment of liquid filling production line, the main working principle is to adopt imported microcomputer to control peristaltic pump pulsating frequency, the liquid is filled into the bottle as per requested amount, and then the capping process is done automatically.

Structure

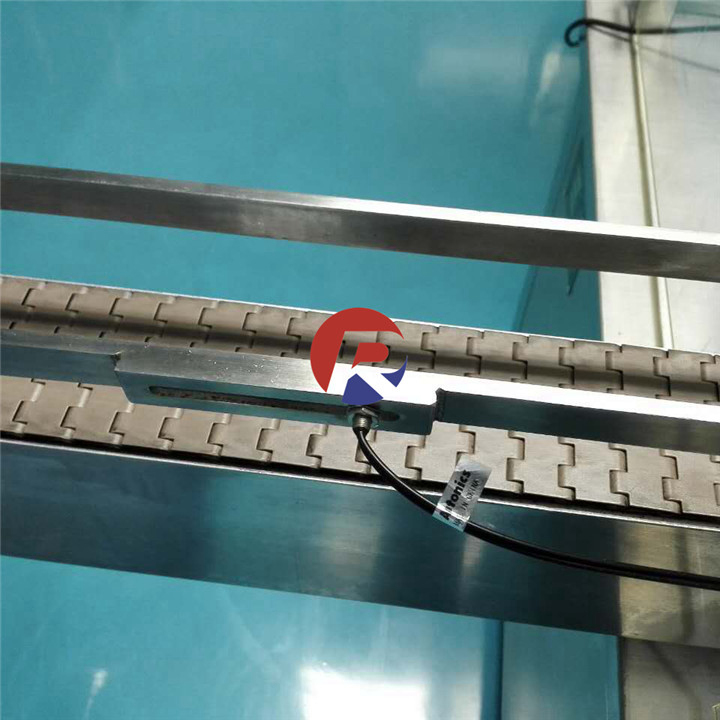

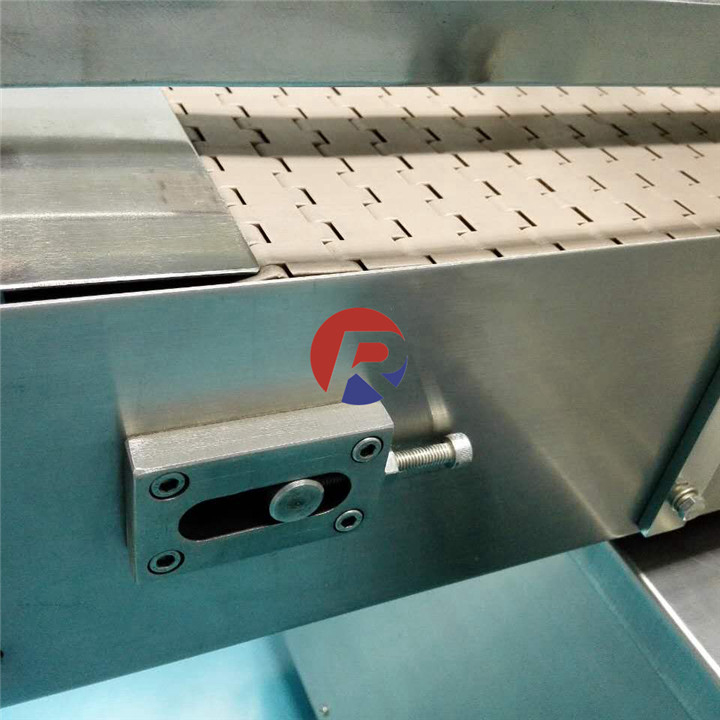

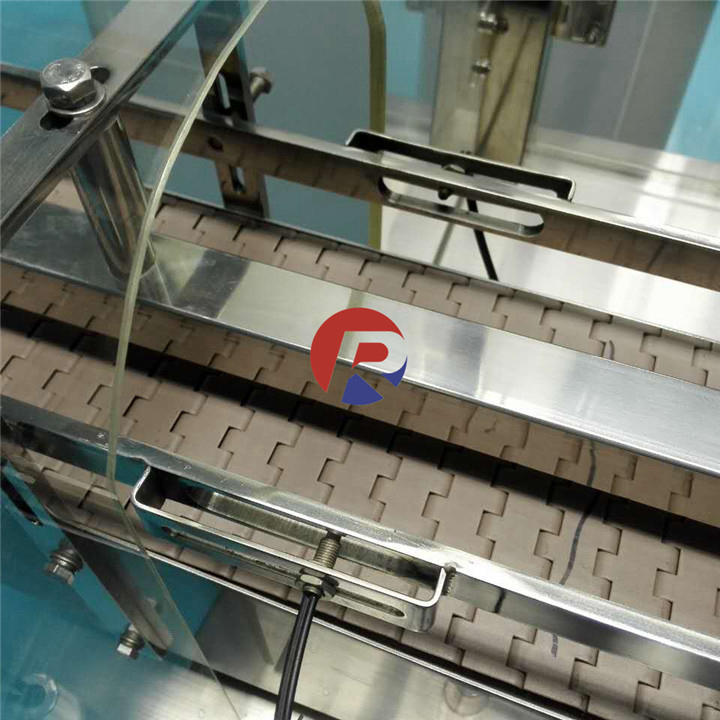

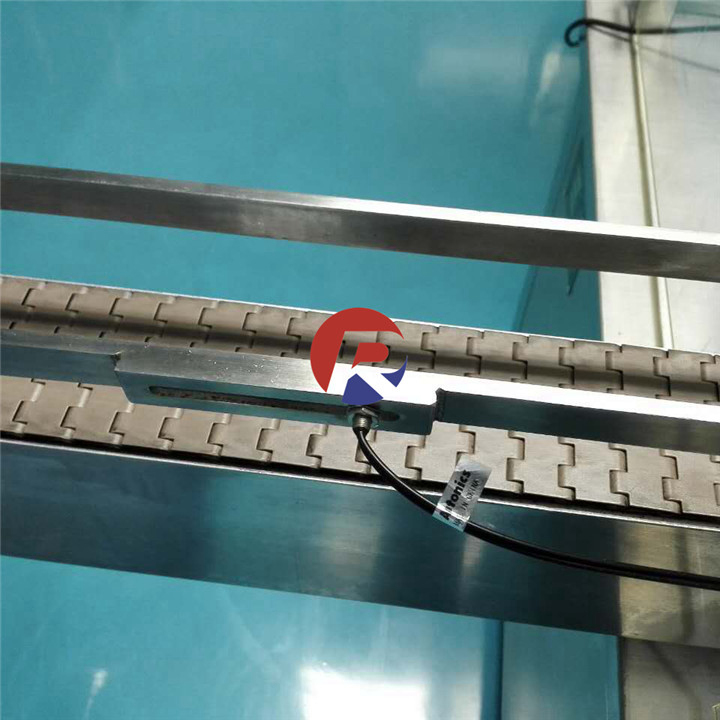

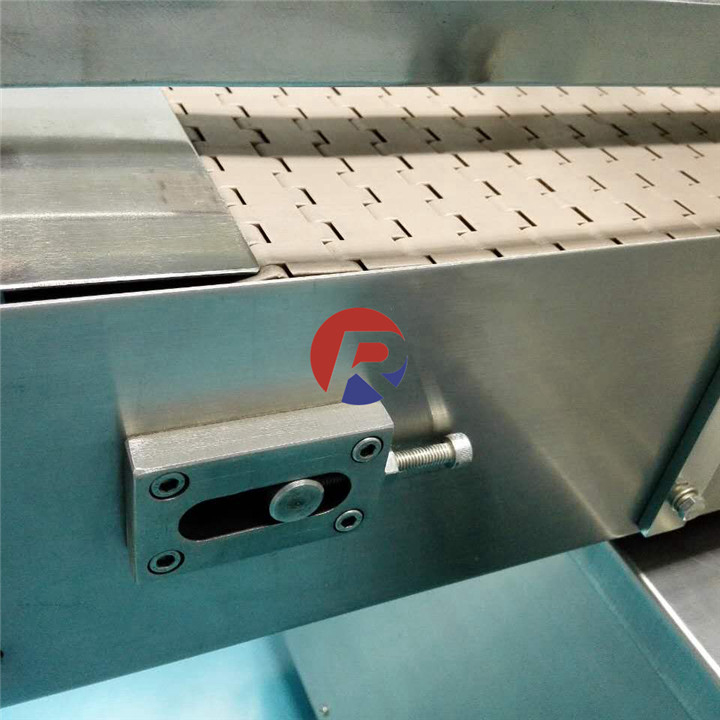

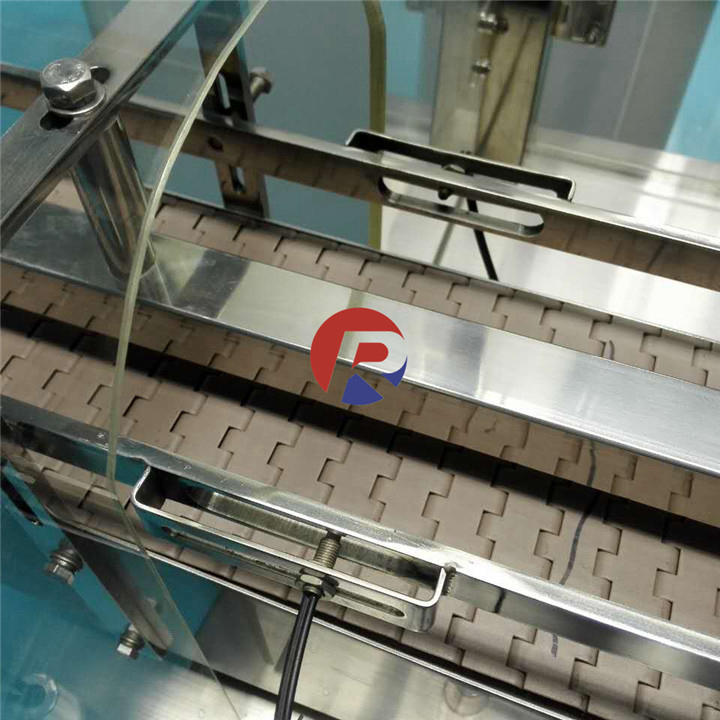

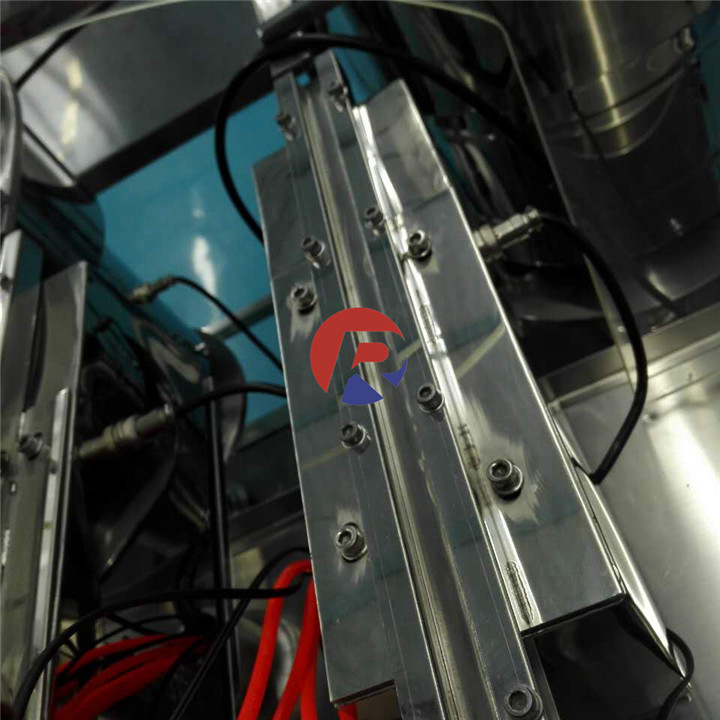

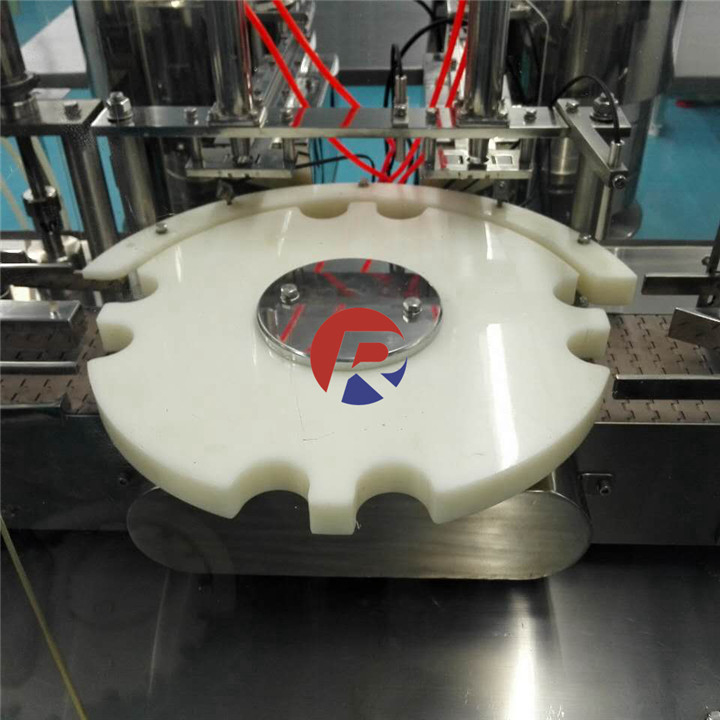

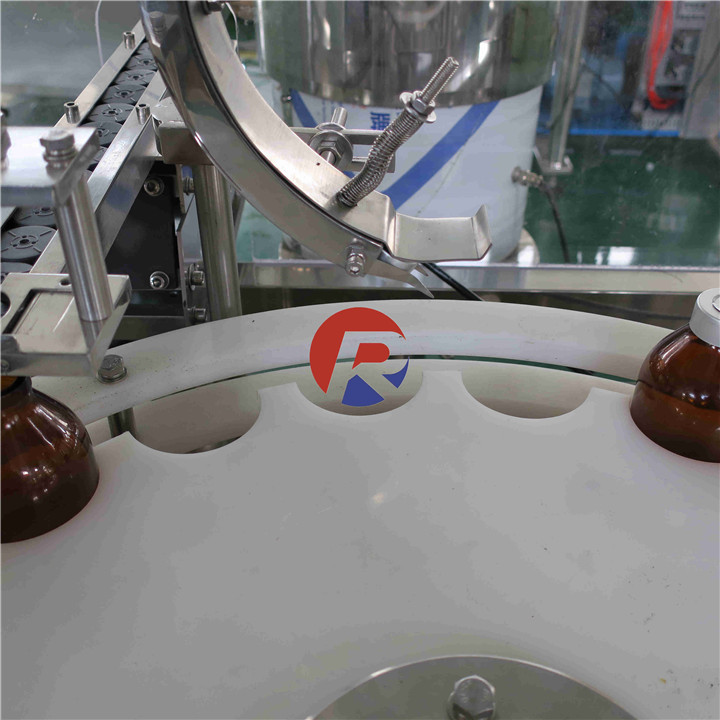

Its main structure is composed out of bottle feeding station, piston pump filling station, rubbers insert station , cap closing station and capping station, conveying mechanism and control system.

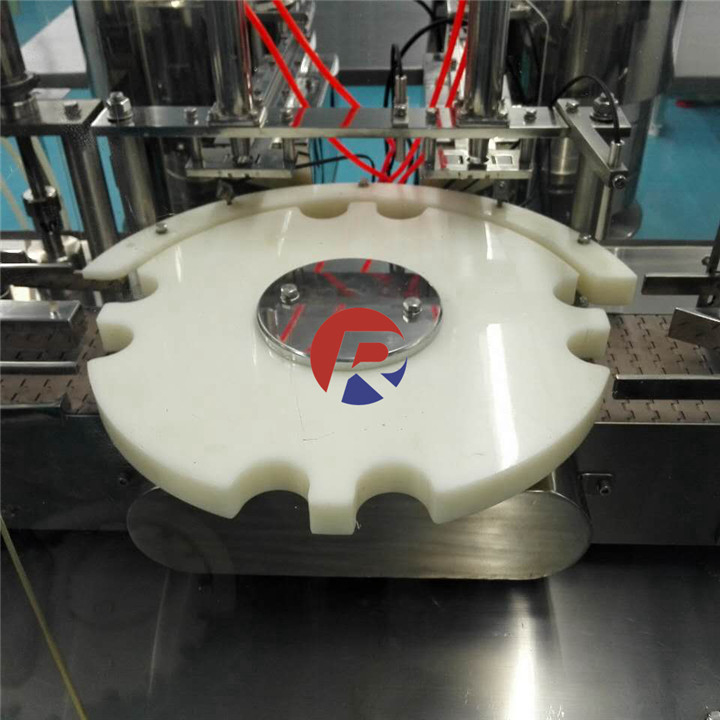

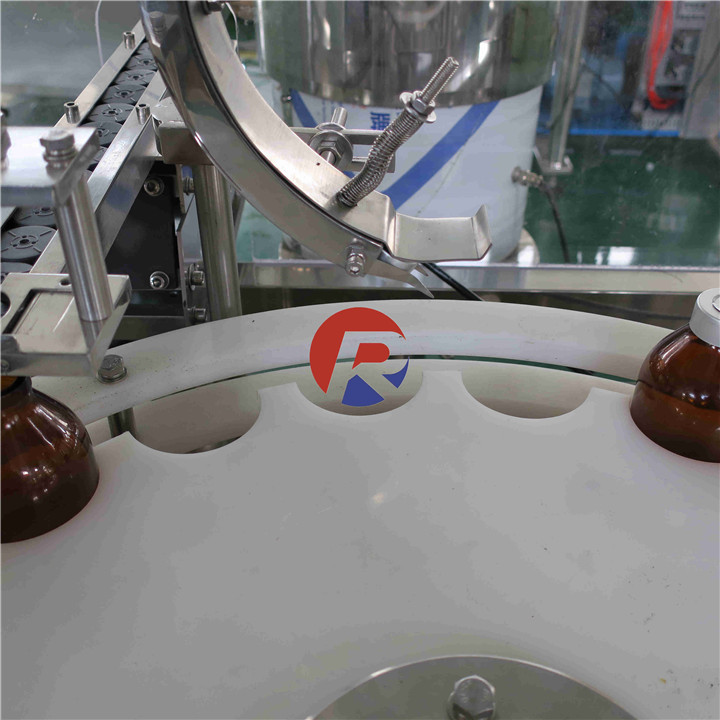

1) Bottle feeding and exiting station: it is composed of the bottle turn table, used for bottle sorting and feeding and guiding it to its destination line

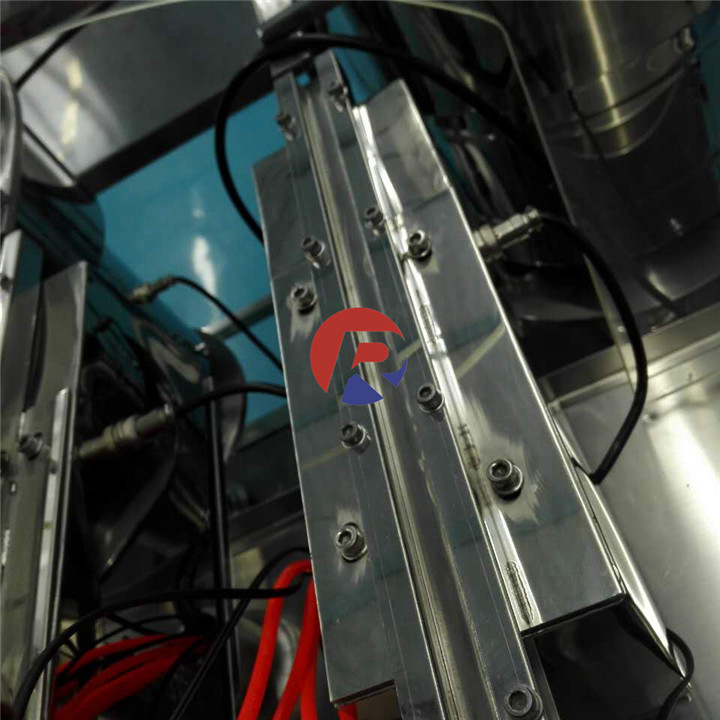

2) Piston pump filling: there are 4 or more piston pumps for filling, microcomputer is used to control frequency, thus volume dosing pump filling is accurate. With such back function to make sure here is no leakage of liquid.

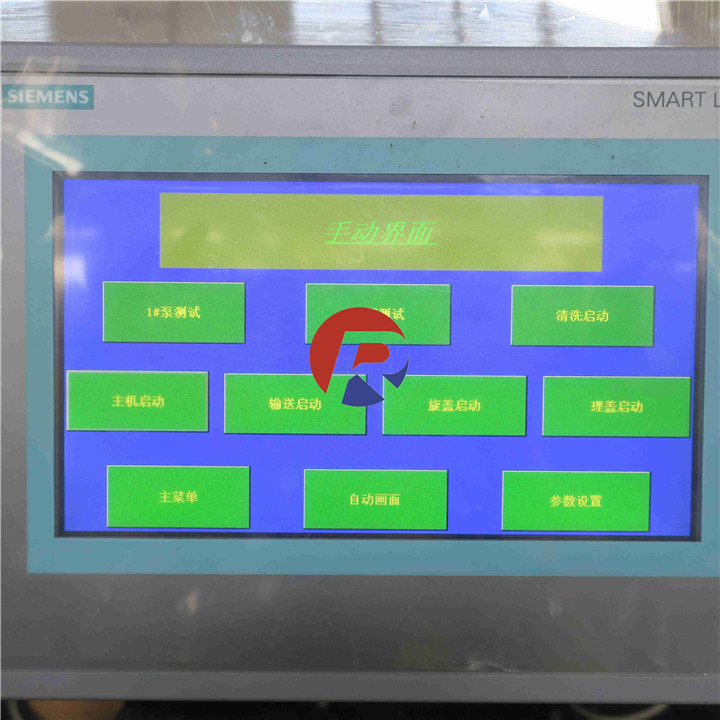

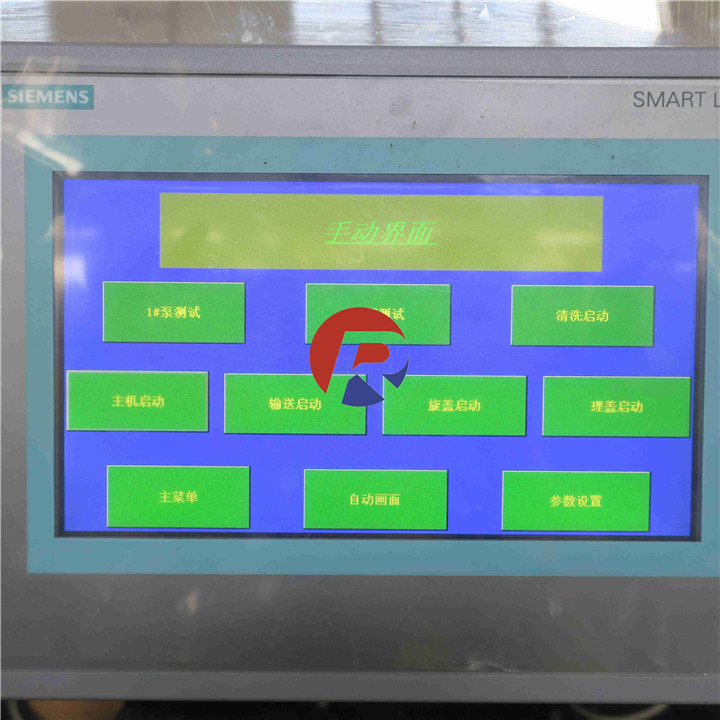

3) Control system: adopt variable frequency motor for variable frequency speed control. Since the filling amount is adjusted through stepping motor through microcomputer, the filling amount could be adjusted without machine stop.

Characteristic

a) The microcomputer controlled liquid filling metering, filling executed by peristaltic pump

b) No bottle no filling, machine stop or auto alarming, no cap automatic machine stop.

c) The touch screen display operation

d) It is equipped with automatic frequency controller, bottle automatic counting.

e) The liquid filling system equipped with anti-drip settings.

f) Automatic bottle feeding, liquid filling, capping.

g) MOC SS316L

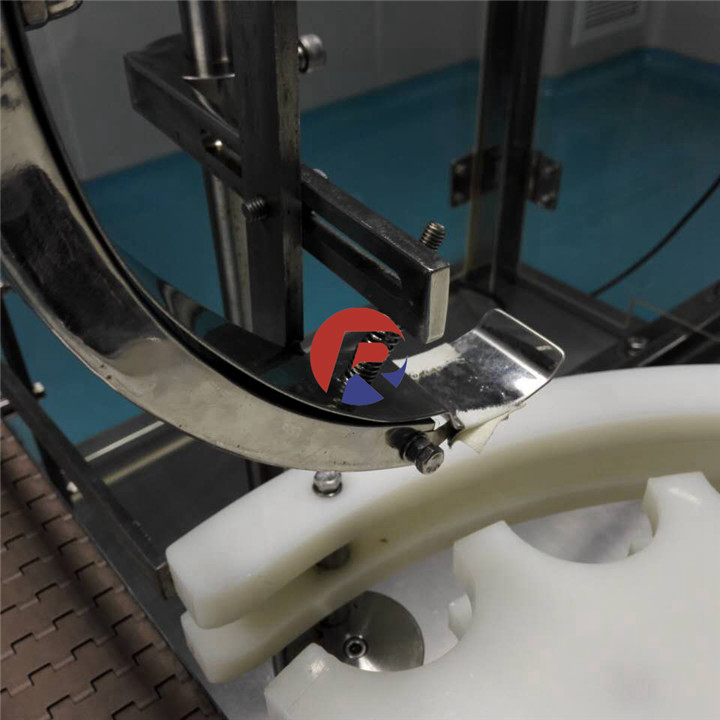

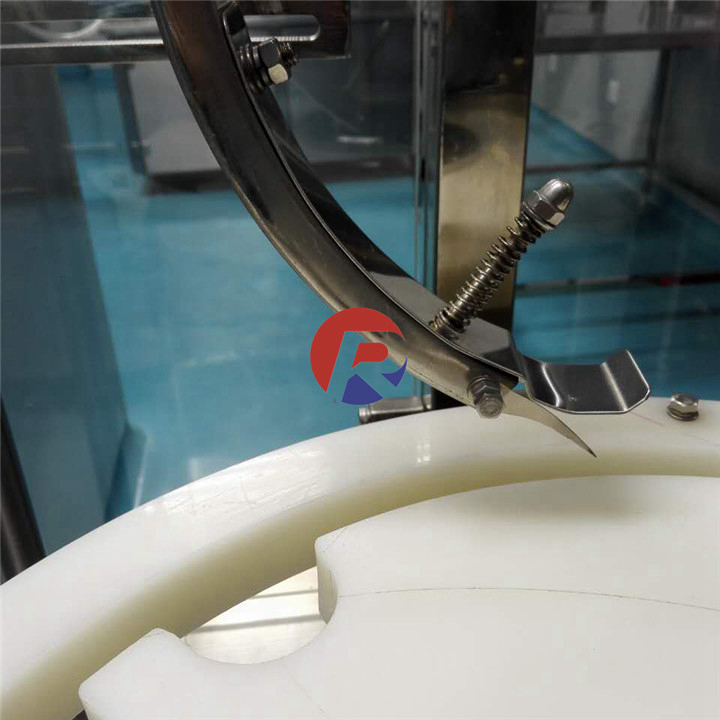

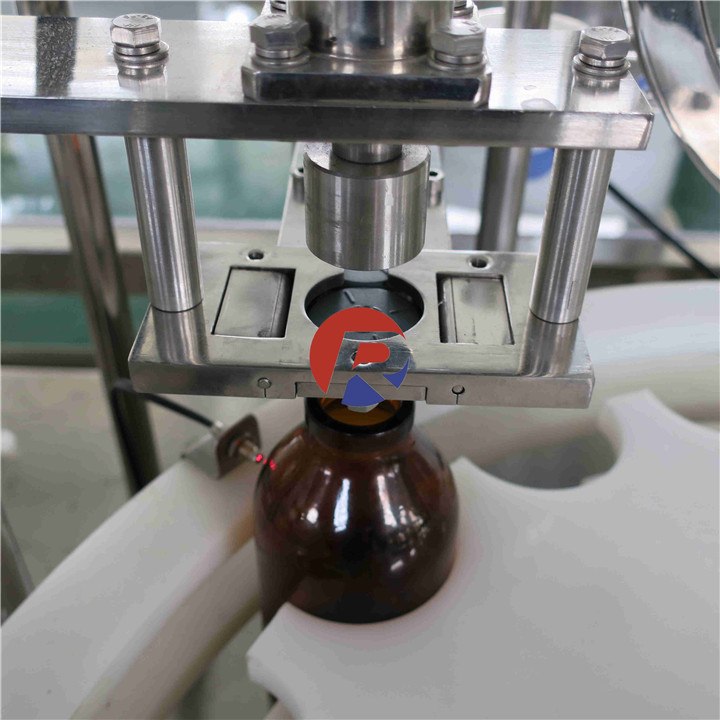

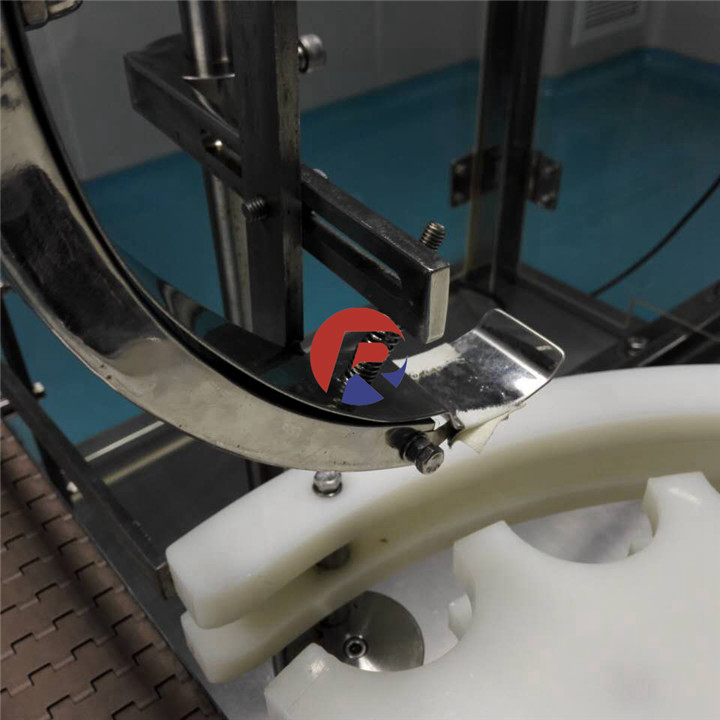

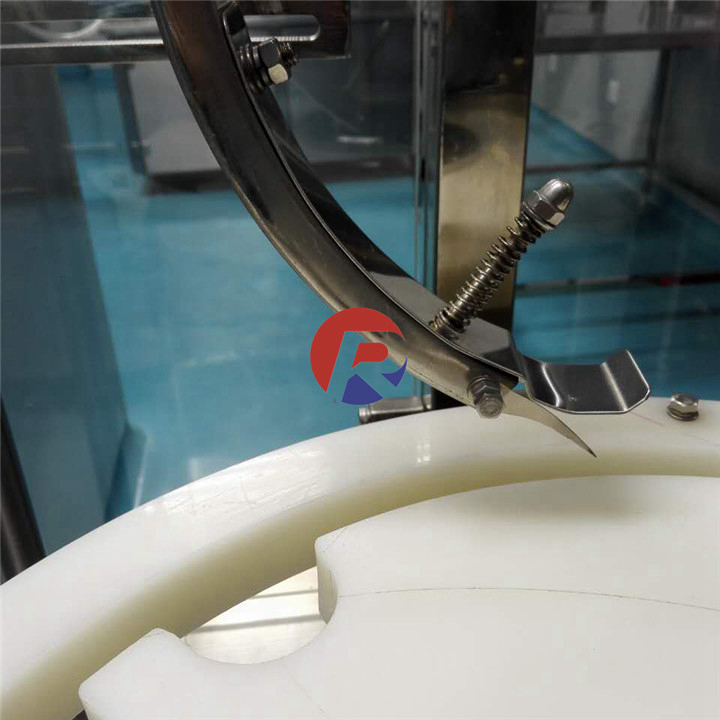

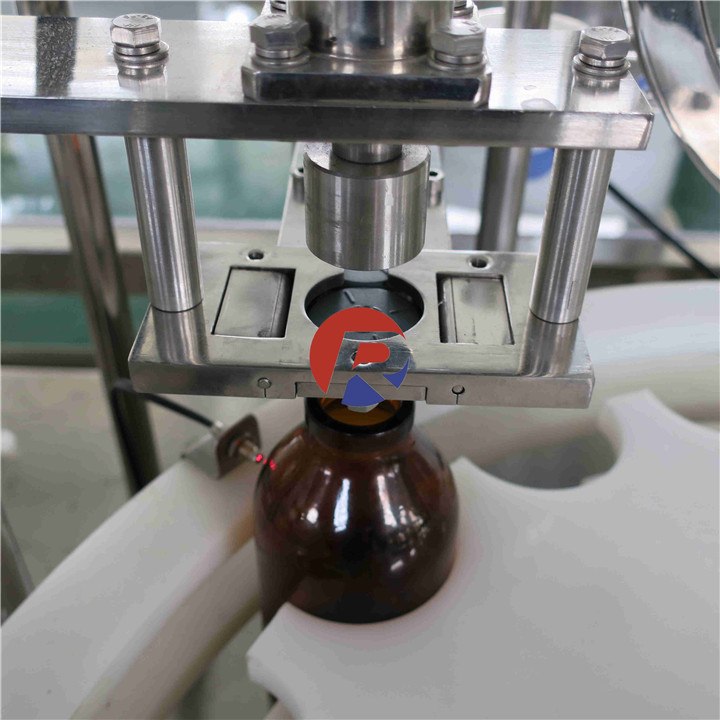

4) Capping Station

* The capping station features with adjustable speed, accurate positioning, reliable capping, stable operation, low noise and low damage caps rate.

* Main Technical Parameters

* Applied Bottle: plastic bottle or glass bottles;

Working principle:

The bottom table rotates driven by the reducer, and it will drive the turn table through the tracking pole, the small gear on the rotation heads will rotate along with big gear the rotation heads will move up and down with the cam curve. The bottle are fed into the expected position along with the track, cam mechanism will hold it tight, the cap is fed by cap arrangement system and fed into capping device, the rotation head will bite the cap and press onto the vial.

Technical parameters:

1 | Application | 30-500ml |

2 | Power | 380V 50HZ |

3 | Supply | 4.3KW |

4 | Filling system | 2- 12 piston pump filling |

5 | Capping heads | 2-8 heads |

6 | vacuum | 0.066MPa |

7 | Vacuum consumption | 20m3 / h |

8 | Filling accuracy | ≤±2% |

9 | automatic capping rate | 99.5% |

10 | Noise | < 70dB |

11 | Dimension (LXWXH) | 3240 x 900 x 1500 (mm) |

12 | capacity | 20ml / 120 bottles/min |