technology key parameter:

Power: Triphase 380v, 50Hz

Total Power: 200KW(gluing machine, air-compressor excluded)

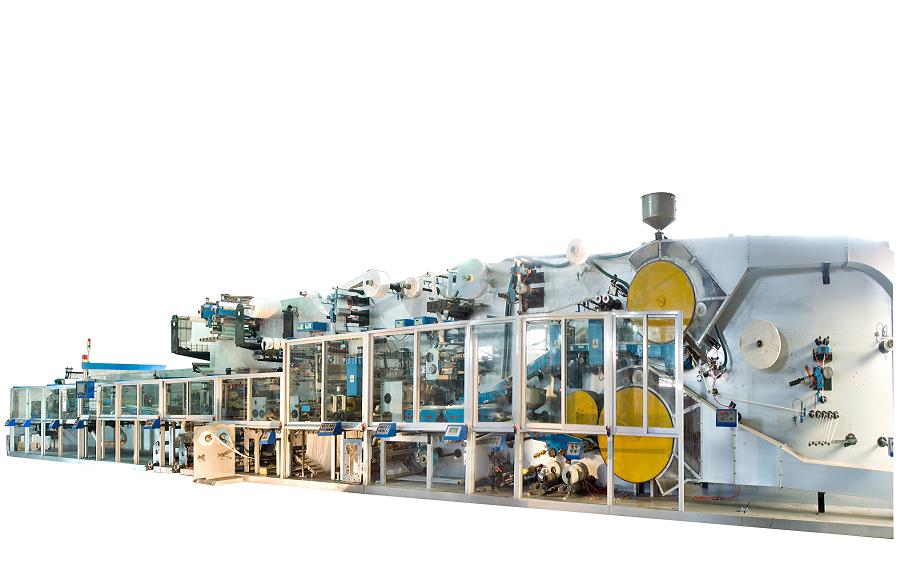

Dimension(L× W× Hmm): 29000mm× 3000mm× 3250mm

Design speed: 120-150PCS/min

Qualification Rate: ≥96%(gluing machine, material reason excluded)

Characteristic and Functions

1. It can produce two sizes(L. M. )products

2. Mixed manufacture with S. A. P

3. Equipped with high effective pulverizer

4. Two channels formation

5. Equipped with elastic waistline, frontal waist sticking, side waist sticking and solid-protecting, leg-elastic structures

6. Finished products stacked out in a line of triple-fold

7. When lack of material or broken material take place, it will alarm. And it has the ability to eliminate the inferiority when changing or linking the material

8. The Driving system adopts sealed gear case, universal joint and synchronous belt. The gear case adopts helical wimble gear type

9. The positioning and molding process are all equipped with electromotive differential to operate and control, regulate relative positions without stopping machine

10. Include PLC+touch-screen system +Frequency-converter

11. Splicing: Equipped with material end cutter in each roll material, splicing can be operated by manual or automatically

12. Unwinding device:

1. Unwinding hydrophobic non-woven: Adopt roll core unwinding, with a constant tension control/ auto splicing

2. Unwinding hydrophilic non-woven: Adopt roll core unwinding, with a constant tension control/ auto splicing

3. Unwinding of PE back film: Adopt roll core unwinding, with a constant tension control/ auto splicing

4. Unwinding of ADL: Adopt roll core unwinding, with a constant tension control/ auto splicing