1. Product introduction:

This forming and cutting incorporated machine designed by our company is all-powerful. The main way is vacuum forming as well as press forming and synthetical forming. It can be used for forming kinds of plastic sheet. This machine adopt PLC control, it has group possesses reliable stability, large forming area, high production and automatic degree. The machine can mainly form the PSP material which is used to produce food container, tray, bowl, cup etc. Forming, cutting, stacking is done in the same machine, saving labor, improving efficient, lowing labor intensity and reducing production cost. Production process is to put foam sheet into forming machine, and product and wastage will come out from the rear part.

2. Demands of public works

1. Voltage: 380V frequency: 50 HZ

2. Production efficiency: 3-5 s/stroke

3. Installed power (approx):168KW

4. Total weight (approx):16T

5. Mounting size: 12m×2m×2.6m

6. Compressed air: 0.4~0.7 m3/min,0.7Mpa

7. Cooling water: 1 t/h (recycle)

1. Including main parts as the following:

No | Name | Picture | Pc |

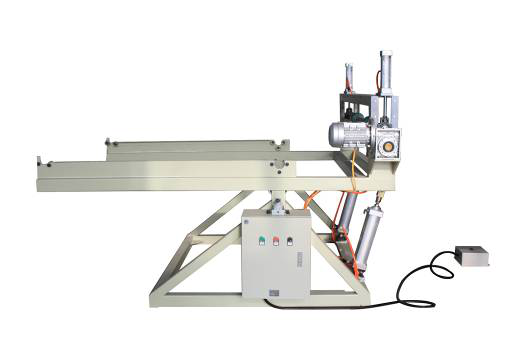

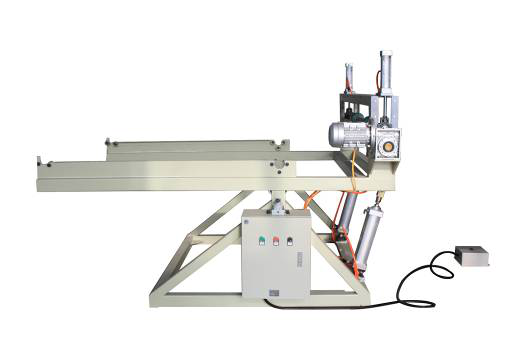

A | Unwinding unit |  | 1 set |

B | Heating unit |  | 1set |

C | Vacuum Forming unit |  | 1set |

D | Cutting unit |  | 1set |

E | Auto stacking unit |  | 1set |

F | Collecting products unit |  | 1set |

G | Scroll winding unit |  | 1set |

H | Electric control cabinet |  | 1set |

I | Program control cabinet |  | 1set |