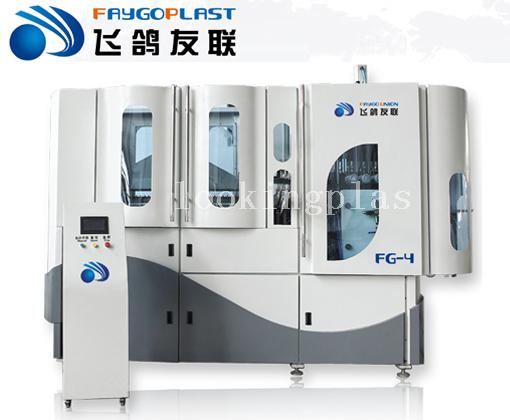

1. Main parameter

Main Parameter |

Cavity number | 6 cavity |

Capacity | 6 cavity-9000-10000B/H(@500ml), 7000-8000B/H(1L), |

Bottle specification | Applicable product: PET bottle |

Applicable bottle volume: 200ml-2000ml |

Applicable bottle neck diameter:28-30mm |

Electricity specification | Total installation power: 51kw |

Total operating power: 30kw |

Machine specification | L4300mm*W1000mm*2300mm |

Total machine weight: 4000Kg |

Our PET bottle blowing machine is a completely new generation of linear blowing machine, distinguished by its high speed, low power and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise and high stability, meanwhile conforms to national beverage sanitary standards. This machine symbolizes the highest level of national linear blowing machines. It is the ideal bottle making equipment for medium and large enterprises.

2. Capacity

1. Capacity: 9000-10000BPH(based on 500ml)

2.Max. Volume: 2 Litter

Total Size: Blowing Main machine: 4.6*1.3*2.3m/

3. Our Blowing Machine Advantages:

Our new design PET bottle machine with below high-tech can save 130000kwh electric one year for customer compare with normal linear six cavity blowing machine.

Our PET bottle blowing machine is a completely new generation of linear blowing machine, distinguished by its high speed, low power and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise and high stability, meanwhile conforms to national beverage sanitary standards. This machine symbolizes the highest level of national linear blowing machines. It is the ideal bottle making equipment for medium and large enterprises.

Advantages:

1. Servo driving and cam linking blowing section:

The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement, equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

2. Small performs distance heating system

Heater distance in the heating oven is reduced to 38mm, compared with the conventional heating oven it saves more than 30% electricity consumption.

Equipped with the air cycling system and redundant heat discharge system, it ensures the constant temperature of the heating zone.

3. Efficient and soft perform inlet system

By rotary and soft preform inlet system, the speed of prefom feeding is ensured meanwhile, the preform neck is well protected.

4. Modularized design conception

Adopting modularized design concept, to make it convenient and cost-saving for the maintenance and changing spare parts.Mold can find position itself, change mold only need 20mins.