Product Description

Welcome to Hubei Ruili Environmental Machinery Co., Ltd, we do research, manufacture, sale on plastic recycling machines, include crushing, washing, drying and granulating.

Plastic Recycling Machines Production Line Specifications:

1. What our machines can do for you?

R: Our machines are to recycle PET bottle, PE PP film, HDPE drum, HDPE chairs, HDPE barrel, plastic containers, shampoo bottle, detergent bottles etc. We are engaged to give new life of waste plastics, and protect environment.

2. What’s the machines working principle:

After get waste plastic raw material, it will go main process of pretreatment of raw material → crushing → washing → drying → package → granulation.

3. How to deal with different kind of impurities on plastic?

A. Dust/mud: friction wash, and rising wash by water.

B. Oil: wash by chemical detergent, such as NaOH. The waters in hot washer is residential, and materials can stay here for 10 mins to be washed by chemical.

C. Iron: separate by magnetic separator.

D. Chemical: will dissolved by water.

E. Paper label: crush raw material into flakes, the hot washed, friction washed, it will be removed from plastic easily, then separate out by zig zag separator.

4. How to separate different kind of plastics when production?

Case A: PET bottles recycling, there are PVC labels and PE caps in bottle. We will separate PVC labels by label remover machine. Regarding PE caps, because it will float, and PET flakes will sink, so PE caps will separate out at sink-float washing tank.

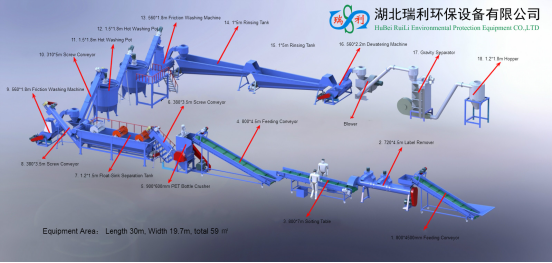

5. What machines will be used in plastic recycling Production Line Process?

A. Feeding conveyor

B. Crusher

C. Screw conveyor

D. Float-sink washing tank

E. Screw conveyor

F. Friction washing tank

G. Hot washing pot

H. Screw conveyor

I. Friction washing tank

J. Rinsing washing tank

K. Rinsing washing tank

L. Dryer

M. Hopper

6. What’s the most popular plastic recycling production line that you manufacturing?

A. PET Bottles recycling production line

B. PE PP film recycling production line

C. PE PP hard plastic recycling production line

D. ABS/PS plastic recycling production line

E. Plastic granulation production line

7. Advantages:

a. Full automatically, only feeding material and package require labor.

b. Capacity range from 300-2000kg/h

c. One stop purchase, we manufacture all of the production line machines by ourselves.

d. Positive feedback from customers

e. Engineers available for overseas.

f. Life span: above 5 years

Our Services

* Inquiry and consulting support.

* View our Factory.

* Training how to install the machine, training how to use the machine.

* Lifelong technical support

* Warranty: 12 month

Packaging & Shipping

Company Information

Certifications

FAQ

1. How many days will it take for delivery?

R: 7 days if in stock, 30-45days for new production.

2. What motor brand you use?

R: we use Wannan motor by default. Siemens motor available when required.

3. May I have video of machine performance?

R: Certainly, pls send us an inquiry, we will share video to you by email/whatsapp/wechat...

4. Are machines easy to install?

R: Yes, all of our machines are drive by motor. Pls place machines at horizontal first, after connected with electricity, it can work.

5. What are the spare parts?

R: Blade, bear, bearing, belt, screws.

6. How long can this machine use?

R: Above 5 years if you use daily.

7. What color can we choose?

R: Our machines generally do green, blue, white, as as request.

8. What incoterms do you accept?

R: FOB, CFR, CIF, FCA, EXW or as negotiation.

9. How to make payment to you?

R: by TT, LC, cash, or else.

To define the suitable product for you, pls tell us below details:

1. What machines are you looking for?

2. What capacity per hour do you need?

3. What’s the voltage in your country?

4. Which quotation your prefer: EXW, FOB, CFR, CIF or else?

5. When do you need to use these machines?

6. Any other special requirements if you have?

Contact

Thanks for your visit, if you are interested, pls contact me:

Lily by +86-15972158719, or lily@ruilimachinery.com.

HUBEI RUILI ENVIRONMENTAL MACHINERY CO., LTD