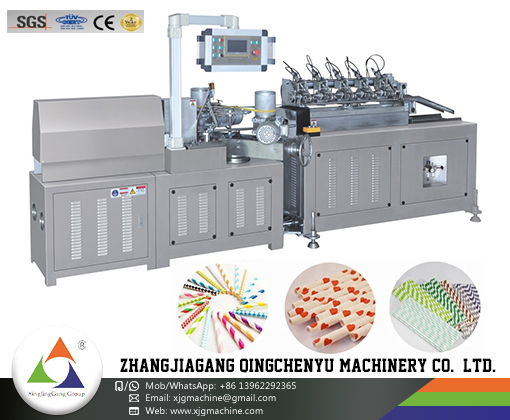

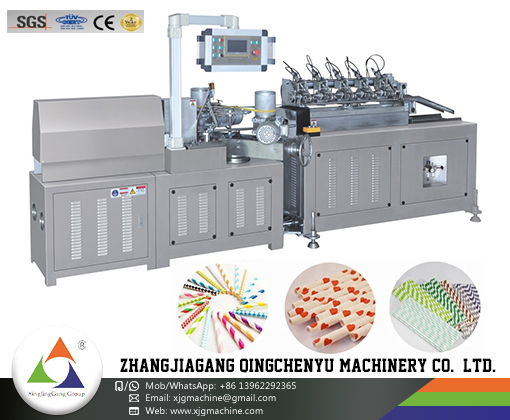

Descriptions: This Machine is suitable for producing different sizes of paper straws, such as 5mm; 6mm; 8mm; 10mm etc.

1. Adopted with PLC controller; main motor is equipped with variable frequency speed regulation; touch screen man-machine interface. Easy for parameters setting & operating.

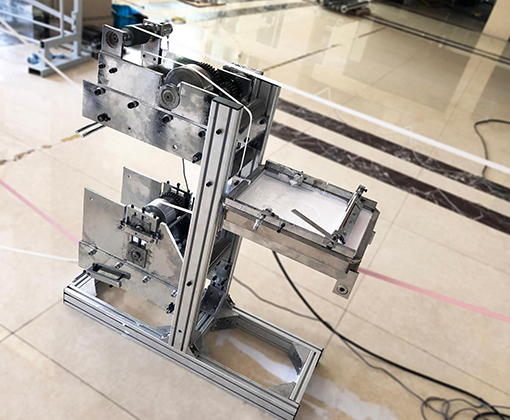

2. Cutting section adopted with numerical multi-blades cutting system. Servo synchronous tracking cutting system makes it higher precision and multi-blades cutting makes it higher efficiency.

3. Machine body and main spare parts made by stainless steel instead of painting. Ensure the hygiene and environmental protection of the products.

Technical Parameter | Control system |

| Number of roller | 3 layer | Main motor | 3 KW |

| Tube diameter | 5-12 mm | Reducer type | RV110-1:15 |

| Wall-thickness | 0.5-1 mm | Conveyor reducer | RV 30/40-1:7.5 |

| Core mould fixed | Flank chuck | Servo motor | Teco,China |

| Winding head | 2 | Servo driver | Teco,China |

| Cutting way | 6 multi-blade | PLC controller | SIEMENS |

| Gluing way | Single side | Touch screen | SIEMENS |

| Operator | 1-2 person | Inverter | ABB Switzerland |

| Winding speed | 30-45 m/min | Electric part | SIEMENS |

| Speed control | Inverter | Single part | ABB |

| Cutting control | Servo Sync | Pneumatic part | AIRTAC |

| Air pressure | 0.6Mpa | Fix length way | Encode |

| Power supply | 380V*3P/50Hz | Configuration |

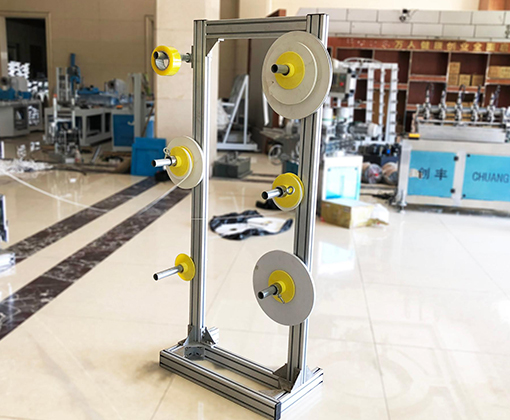

| Straw collecter | Auto | Paper reel stand | 3 layers |

| Angel correction | Auto by motor | Glue system | 3 layers |

| Language | English | Conveyor | 1 set |

Measurement & weight | Blades | 6 pieces |

| Mainframe size | 3000*1400*1450 | Belts | 5 pieces |

| Area space | 6000*6000 mm | Core mould | 2 set |

| Weight | 1200 KGS | Useful tool | 1 set |

Multi-knives Inline Cutting System

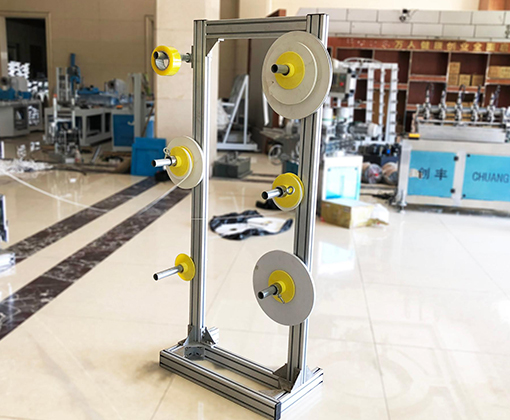

Aluminum-Profile Paper Reel Stand

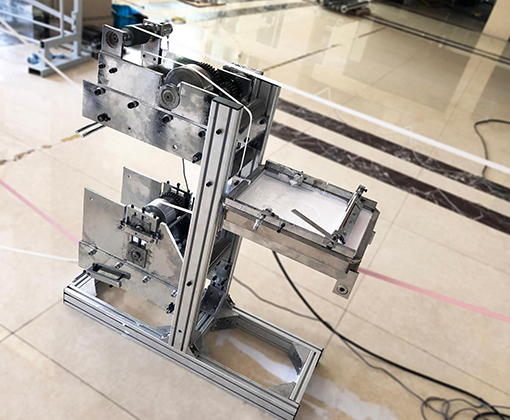

Aluminum-Profile Glue Unit

Finished Product