Product Description

PE PP barrel tank flake recycling pelletizing machine

PE PP rigid hard flake force feeder pelletizing line

PE/PP rigid hard flake granulating line

plastic granulator

Quick Detail for PE PP barrel tank flake recycling pelletizing machine:

1. Rigid milk bottle, shampoo bottle, chemical barrel, pipes, rigid material, plastic product e.g.

2. Single stage, single screw

3. Water ring die face cutting

4. CE certificate

5. Lower power consume,

6. More stable output

7. Smooth & full pellets

8. after sale service

Material shapes: agglomerated film, crushed material (PE, PP)

Diversified option of PE PP barrel tank flake recycling pelletizing machine:

1.Normal forced feeder pelletizing line

work procedure:

Crushed film→spiral charger→feeder→mother extruder →hydraulic screen changer →baby extruder→hydraulic screen changer→pelletizing system →air transmission →silo storage

2.Side forced feeder pelletizing line

work procedure:

Crushed film→air transmission→side forced feeder→mother extruder →hydraulic screen changer →baby extruder→hydraulic screen changer →pelletizing system →air transmission →silo storage

Applications of PE PP barrel tank flake recycling pelletizing machine:

1. Applicable plastic materials: PE, HDPE, LDPE,PP, etc

2. Material shapes: rigid flakes, agglomerated film,

3. Note: depending on different material properties, various downstream equipments are needed.

How it works:

1. Screw charger uploading the material by timer

2. Feeder and extruder is controlled by inverter

3. Different L/D for different material

4. Nature degassing, vacuum degassing adopting for moisture

5. Water ring die face cutting or strand noodle cutting

6. Mother-baby model for stable output

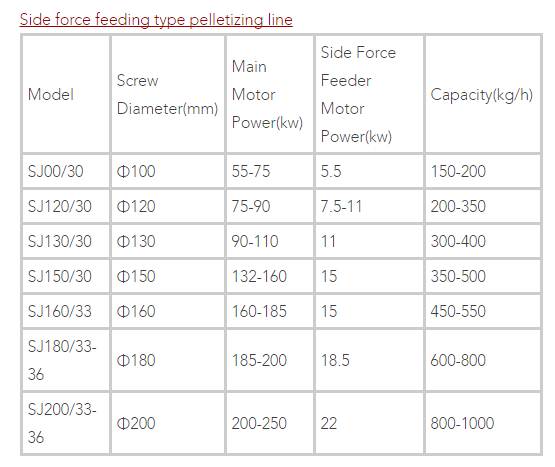

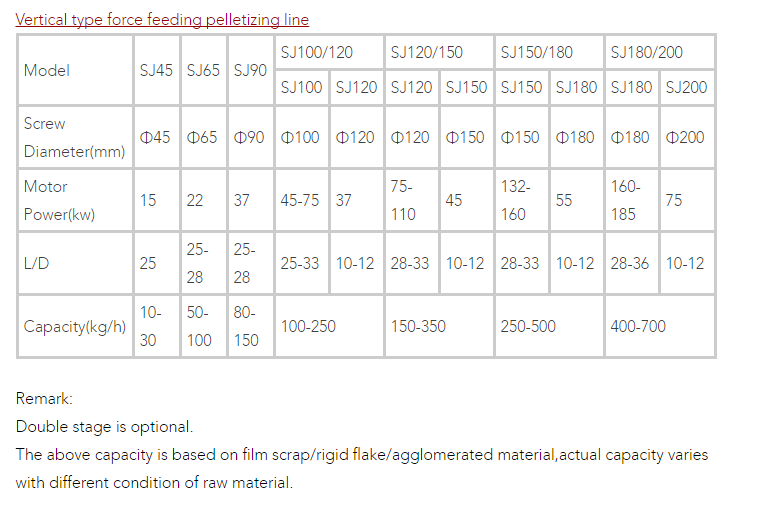

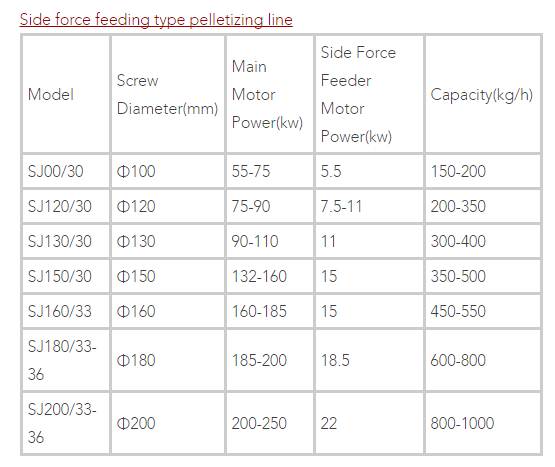

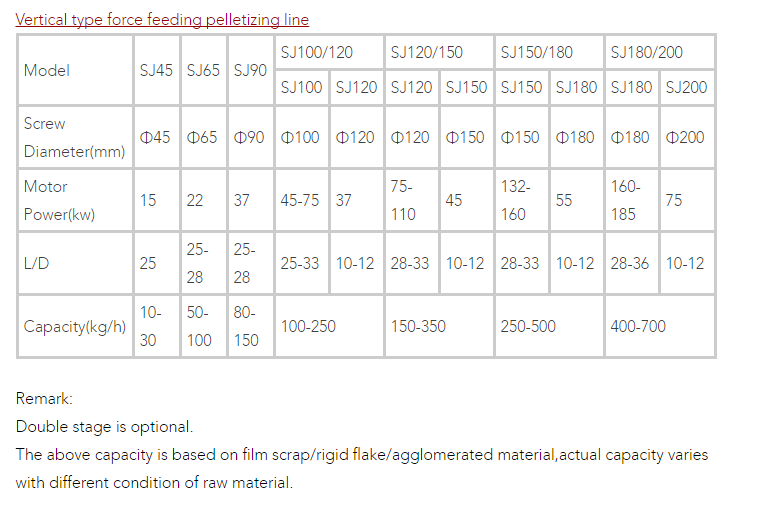

Technical parameter: