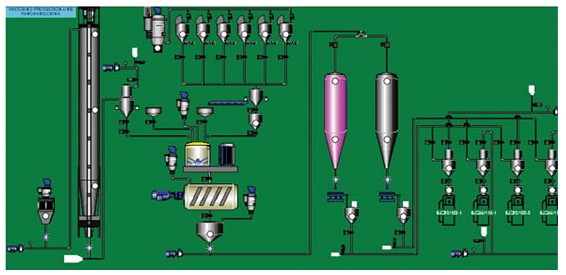

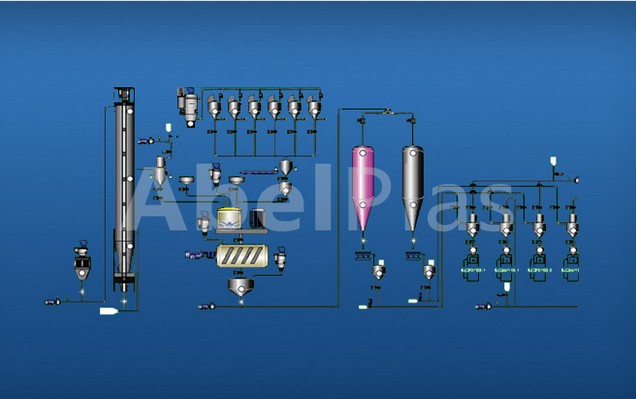

Craft procedure

A、Dump PVC etc. Materials

PVC and other material are manually poured into dump station and conveyed into 4 storehouses pneumatically. Workers will be alert by the material meter signal to feed or stop. The store house is equipped with loosing material device

B、Measurement and feeding of materials

Main material is fed into 3 electronic balance and then mixer by rotary valve below store house.

C、Putting auxiliary materials

Auxiliary materials are fed by step in feeder after manual measuring. When mixer ask auxiliary materials, the pneumatic board valve come to open, step in feeder starts, infrared ray test the material overpass, step in feeder stops, time-lapse stop pneumatic board valve.

D、Heating mixing and cooling mixing

In heating mixing, at the same time water is drained by compulsion absorption device; when materials reach the set temperature, discharging valve will open automatically and material enter cooling mixer. When material come to set temperature of cooling, cold discharging valve will open automatically and materials move into a storehouse of 1 m³

E、Dust catch

PVC, dry material and broken materials will be clean by an impulse dust catcher; this device can adjust pulse frequency and width.