Feature & Function:

Single Wall Corrugated Pipe production Line consists of extruder, die, moulding machine, and winder or stacker. It is

used to process single wall corrugated pipes with diameter from 40mm to 200mm, which are used for wire and cable, and used as drainage pipes of washing machine, vent pipes, etc

1. Extruder: high efficient screw, hard gear surface gearbox, uniformed raw material heating, good plasticization, high extrusion speed.

2. Corrugation forming machine: closed structure, module link in the overall closure base does round-trip running in the running tunnels.

3. Forming mods: it is made of hard steel, with a rigorous use of CNC finishing materials produced to ensure the hardness and precision of the molding modules. These modules are easy and convenient to change

4. Coiler :Single position or double position with torque motor.

5. Electrical parts: ABB inverter, Schneider contactor, RKC temperature controllers etc.

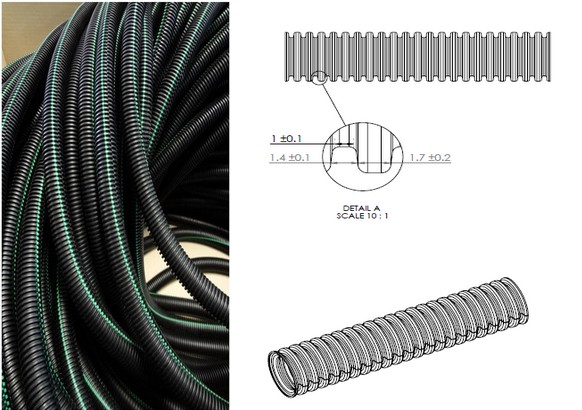

6. Final products :

TECHNICAL DATA:

Line Model | Extruder model | Production scope | Output | Total Power | Production speed |

PE-40 | SJ-45/30 | Φ6-40mm | 60kg/h | 25KW | 8-11m/min |

PE-63 | SJ-65/30 | Φ12-63mm | 80kg/h | 30KW | 8-13m/min |

PA-40 | SJ-45/28 | Φ6-40mm | 60kg/h | 25KW | 8-11m/min |

PVC-50 | SJ50/105 | Φ16-50mm | 100kg/h | 27KW | 8-15m/min |