| Quotation Validity |

|

| Payment terms | 30% advanced payment, balance payment T/T 10 days before the shipment. |

| Production time |

|

| Delivery | F.O.B. Shanghai, goods loaded into container, packing included |

| Guarantee | 1 year |

| Environment Condition |

|

| Location | Indoors |

| Power supply | No dangerous area |

| Power | 3-phase 4 wires sructure,380V/3P/50Hz |

| Total power | 70KW |

| Average energy consumption | 42KW—45KW |

| Oil pump motor power |

|

| Hydraulic system | Servo pump |

| Humidity degree | ≤95% |

| Temperature | 0-35℃ |

| Cooling water | ≤20℃, ≥0.3Mpa |

| Water consumption | 5T/H |

| Air pressure | 0.6Mpa |

| Air consumption | 24m³/h |

| Suitable material | HDPE/PP |

| Max container volume: | 5L |

| The max. plasticizing capacity | 90kg/hr |

| NOTE | The output varies according to the materials and the operation conditions. |

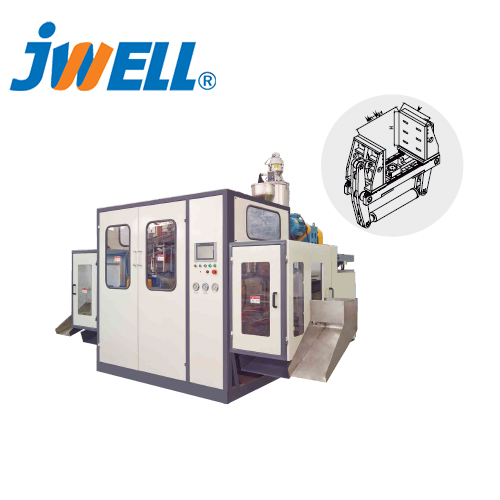

| Equipment list | JWS80/25 Single screw Extruder 1set |

| JWS35/25 Single screw Extruder 1set |

| MOOG100 Parison Controller 1Set |

| Blowing pin device 2set |

| Continuous type Die head 1set |

| Mold open and close device 2set |

| Take out robot 2set |

| Hydraulic system 1set |

| Pneumatic system 1set |

| Electrical system 1set |

| Specifications of the Production Line |

|

| JWS80/25 Single screw Extruder |

| Screw |

|

| Diameter | 80mm(double station) |

| L/D | 25:1 |

| Material | 38CrMoAlA |

| Treatment | Nitriding heat-treatment |

| Barrel |

|

| Material | 38CrMoAlA |

| Treatment | Nitriding |

| Heating control zones | 4 Zones |

| Heating power | 3.7KW×4 |

| Cooling system | By blower fan |

| Cooling power | 0.25KW×4 |

| Gearbox |

|

| Material of the body | QT225 |

| Gear type | Helical gears |

| Material of the gear | 20CrMnTi |

| Heat treatment of the gear surface | Quenching |

| Bearings Chinese | famous bearing |

| Lubricating system | Press system |

| Cooling System | Equipped with separated Cooling System |

| Feeding block |

|

| Water circled cooling system |

| Material | Q235 |

|

|

| Driving motor | AC motor MADE IN CHINA |

| Power | 37KW |

| Control System | ABB inverter |

| Auto loader300Kg/h |

|

|

|

|

| Die Heard | Continous type Die head

(Including Heating Ring ) |

| Heating Control Zone | 4 zones |

| Heating Power | MAX 9KW |

| Material of the die | 38CrMoAlA |

|

|

| Mold Opening and Clamping Device |

|

| Platen size | 350mm×400mm |

| Max. mould size | 360mm×400mm |

| Max. die pin diameter | 145 mm |

| Spaces between platens | 150mm×510mm |

| Platen moving stroke | 450mm |

| Clamping force | 70 KN |

| Clamping way driven | by hydraulic |