Home > Product

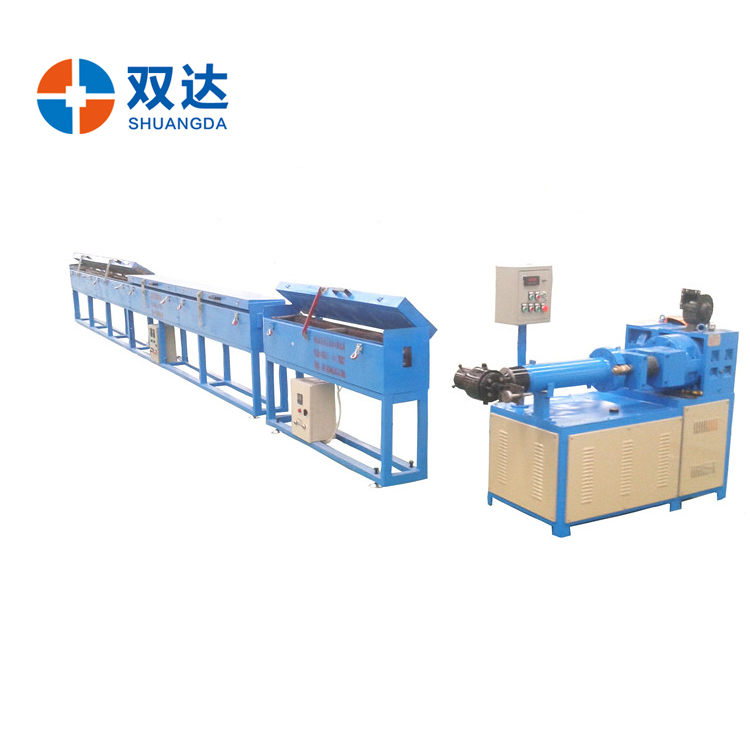

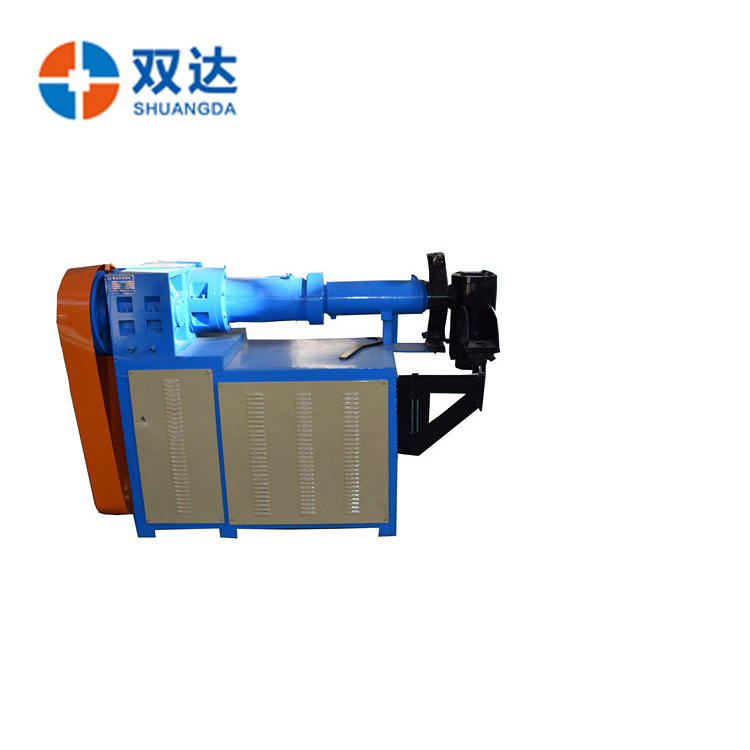

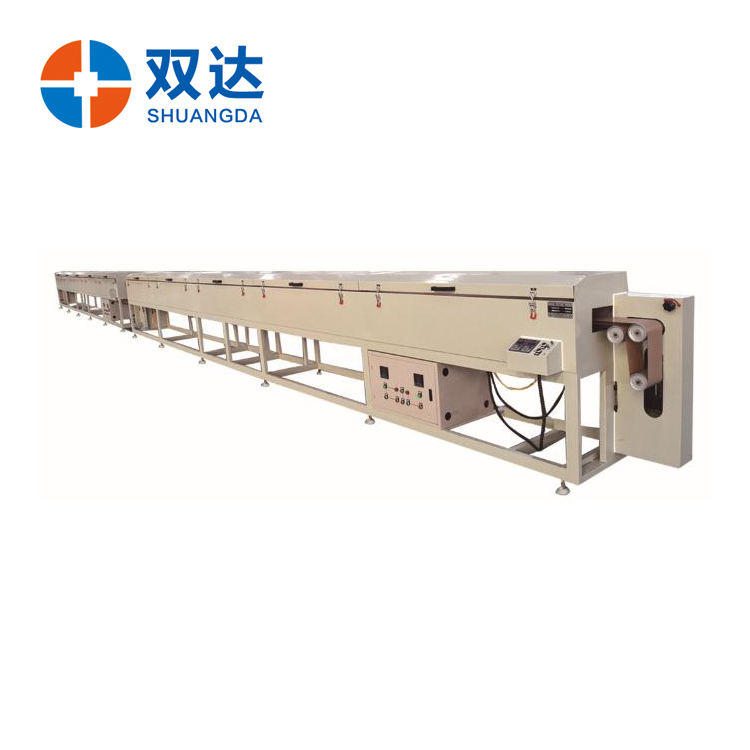

Categories > Silicone cable extruder production line / Cable extrusion equipment / Silicone extruder

Silicone cable extruder production line / Cable extrusion equipment / Silicone extruder 980 Favorites

| Product Categories: Silicon Commodity Processing Machine | |

| Packaging Details: | Trademark: |

| Certification: | |

| Payment Terms: | |

| FOB: | HS Code: |

| Loading Port:Tianjin | |

| Hebei Shuangda Rubber & Plastic Machinery Co.LTD | |

|---|---|

| Company type: Manufacturer | Credit:

|

| Main products:Rubber extruder / Plastic extruder / Plastic granulator | |

Contact Supplier

Reminding

Message has been sent successfully.