2019 china hot sale film blowing machine

Description of Plastic 3 layer Film Blowing Machine

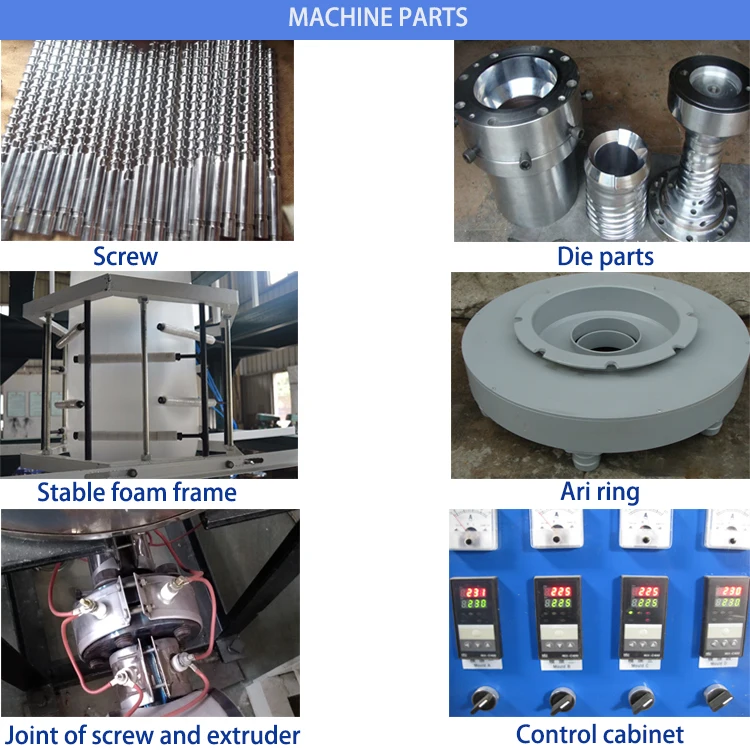

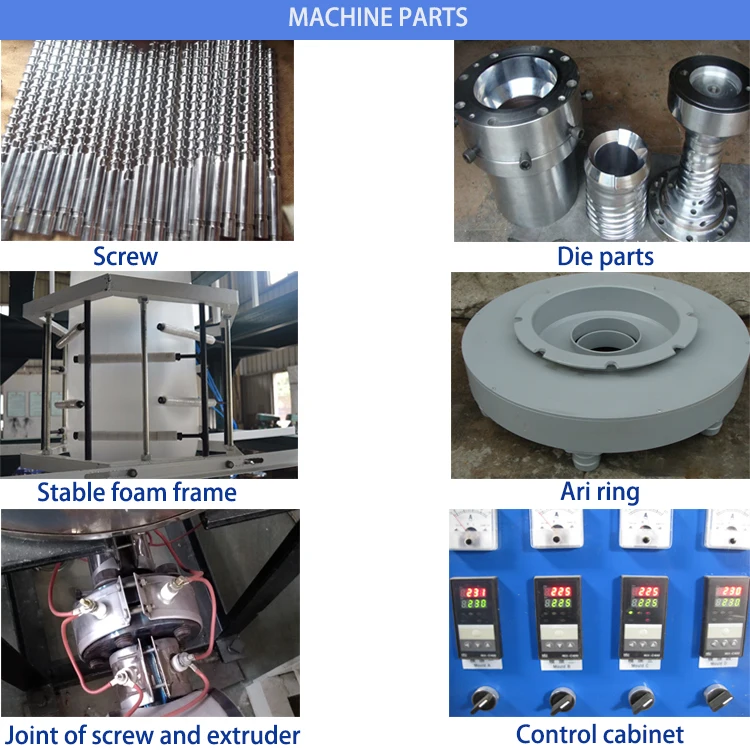

1- Screw and barrel about Plastic 3 layer Film Blowing Machine

The screw and barrel are made of 38CRMOALA high quality alloy steel. It is after fine finishing and nitride treatment. It has high hardness, strong resistance to corrosion, durable service.Material of screw: made from sacm-645 alloy steel .hard chromed plated and nitride.

2- Die head about Plastic 3 layer Film Blowing Machine

The die head is plated with hard chrome, of screw mandrel type structure. It can strengthen the intensity and evenness of plastic film.

3- Rewinder about Plastic 3 layer Film Blowing Machine

The rewinder adopts pressure friction rewinding or center rewinding device, which is driven by torque motor. It is even and smooth rewinding and easy roll changing.

4- Lifting device about Plastic 3 layer Film Blowing Machine

The lifting device is suitable for various width of film.

If the film width is wider, the lifting device can be lift to higher position.

If the film width is narrower, the lifting device can be lift to lower position.

5- Electric container about Plastic 3 layer Film Blowing Machine

The independent electric container is convenient for operation the machine.

6- Frequency Inverter about Plastic 3 layer Film Blowing Machine

The main motor adopts frequency control of motor speed to improve the speed regulating stability of main motor and save electricity by 30 %. the take-up motor is also adjusted by frequency inverter.

7. traction frame about Plastic 3 layer Film Blowing Machine

theracton frame adopts lifting type. No matter what size the film is, big or small, it can achieve the best effect of cooling

More pictures of Plastic 3 layer Film Blowing Machine:

Product Description

| Plastic 3 layer Film Blowing Machine |

| MODEL | 45 | 50 | 55 |

| SUITABLE MATERIAL | HDPE ,LDPE, LLDPE |

|

|

| FILM WIDTH (mm) | 800-1300 | 800-1500 | 1200-2000 |

| FILM THICKNESS(HD) mm | 0.028-0.18 | 0.028-0.18 | 0.028-0.18 |

| MAX EXTRUSION OUTPUT | 80-130kg/hr | 120-190kg/hr | 150-260kg/hr |

| EXTRUDER |

|

| SCREWDIAMETER (mm) | 45/50/45 | 50/55/50 | 55/65/55 |

| SCREW L/D LENGTH | 28:01:00 |

| SCREW AND CYLINDER MATERIAL | SACM-645/38 CRMOALA |

|

|

| CYLINDER COOLING | 370W×2 /3 | 370W×2 /3 | 550W×2/3 |

| TEMPERATURE CONTROL | 3×3 | 3×3 | 3×3 |

| Average power-consume | 58kw | 70kw | 90kw |

| MAIN MOTOR(KW) | 15/18.5/15 | 18.5/22/18.5 | 22/37/22KW |

| TYPE OF DIE |

|

|

|

| DIE SIZE (mm) | 200/250 | 250/300 | 350/400 |

| Temperature control | 4 |

| AIR RING | 1 |

| Air blower | 5.5kw | 7.5kw | 11kw |

| TAKE UPUNIT |

|

|

|

| ROLLER WIDTH(mm) | 165×1400 | 165×1600 | 190×2100 |

| TAKE-UP SPEED | 5-60m/min | 5-60m/min | 5-60m/min |

| Take-up motor | 1.5KW | 1.5KW | 2.2KW |

| WINDING UNIT |

|

| Type | Surface friction type |

|

|

| Winding motor | 1.5kw | 1.5kw | 2.2kw |

| Winding speed | 5-60m/min | 5-60m/min | 5-60m/min |

| OVERALL DIMENSION(LXWXH) | 7.5x5.5x7m | 8.2X5.8x7m | 9X6.4X8.2 m |

Company brief introduction:

Laiwu Guanhua Plastic Machinery Co. Ltd is the top three original factory which specialize

in manufacturing all kinds of plastic machine in China. Our factory have more than 15 years

experience in produce plastic machine, below are our Main products:

1) Greenhouse film blowing machine

2) Geomembrane film blowing machine

3) Mulch film blowing machine

4) ABA plastic film blowing machine

5) PE or PVC heat shrinkable film blowing machine

6) All kinds of HDPE,LDPE and LLDPE packaging film blowing machine

7) drip irrigation hose production line

8) drip irrigation pipe production line

9) PE thin wall pipe production line

10) PE/PVC/PPR pipe production line

Packing and shipping

Certificatins

Cooperation

Contact us

You Will Get Best Offer Within 24 Hours

Attn : klaus xi Mobile &WhatsApp &Wechat : +86-18863443017