automatic PET bottle blow molding machine

Nowadays, the pet bottle making industry is facing a situation where more intelligent, more fast, more energy saving is becoming an unstoppable trend. As a result, the cost for producing each bottle is greatly brought down, whoever finds the right blowing machine for his factory will let himself have competitive advantage in their market.

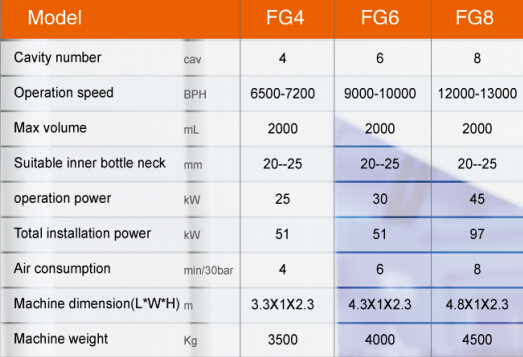

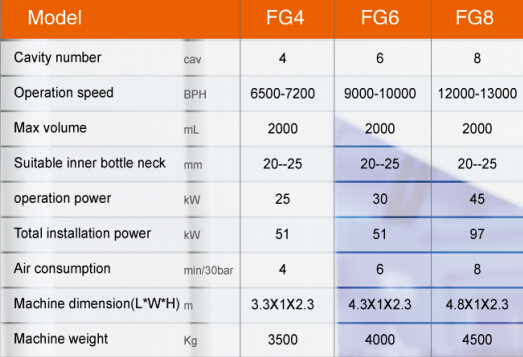

Briefly saying, this new generation blowing machine doubles the capacity(4 cavity 7200 bottles per hour) and half-reduce the power consumption(only two heating boxes, 22kw working power). Compared with the traditional marching type blowing machine(in which the preform is moved step by step), this machine realizes the preform continuously running in the heating oven, this will make sure the each preform heated more evenly, and reduce the reject ratio of finished products.

More important is this machine has more reliable structure because it breaks through the traditional design idea for the blow molding part, it adopts the mechanical cam control to integrate the 4 movement in 1 movement, machine is full servo motors electrical control, no need low pressure air compressor, which greatly simplify the machine movement and reduce the machine failure rate.

Besides, if speaking the linear blowing machine, this smart machine maybe the one who knows the end user’s demand best. Thanks to the working experience on the blowing machine frontier more than 10 years, feedback and complains can be collected from hundreds of end users, this helps us to solve the problems before it happens and make the complains into the smart design in this machine. For example, this machine has position fix grooves on the machine frame to make the installation very quickly and efficiently, if position not right, it can not be assembled, no need take time to measure it,quick changing bottle mold only needs 30 minutes.

Last but not least, this machine adopts the excellent aluminum alloy material mainly, more anti-abrasion and more clean, the frame uses the doubled thickness than others to make sure this machine will have longer and better service performance.

13 national patents have been gained by this machine.