Application:

The V-T feeder is designed to provide volumetric feeding program for a wide variety of materials including poor flowing powders, fibers and flakes.

Design:

Twin screw feeder with interchangeable feed screws is mounted on painted steel base plate. All material contact parts are stainless steel.

The feeder is easily disassembled for cleaning or change over. Special design of feeding bowl is unique, horizontal agitator isequipped to

improve material filling into screw flight.

Controller:

Motor speed regulator will be frequency inventor. Frequency inverter can be supplied by customer.

Actual feeder screws are determined based on the material characteristics. The following is estimated feeding

rates for free flowing materials. For feeding rates at either end of the range, feeding testing is recommended.

Feed Model | Feed rates | Material | Asymmetrical Hopper | Symmetrical Hopper |

V-T28 | 15-500 L/h | Free/poor flowing powder、mixture of powder and pellet as well as fiber, flake | 40L/80L | 10L/40L/80L/120L |

V-T38 | 60-1600L/h | 80L/120L/150L | 80L/120L/180L |

V-T46 | 300-4000L/h | 80L/120L/150L | 120L/180L/300L |

Material contact parts 304 Stainless Steel

Seals Neoprene

Painting Light Grey

Options :

Standard Hopper

Vertical agitator

Manual/ Auto refill

Vertical outlet

Special paint/ finish

Extended screws

Stainless steel base plate

Configuration :

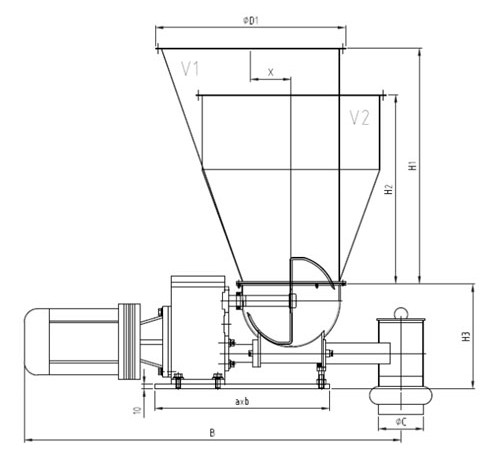

| Type | A | B | H3 | C | axb | Asymmetrical hoppers | Symmetrical hoppers |

| V1(L) | H1 | D1 | X | V2(L) | H2 | D2 |

| T28 | 218 | 800 | 278 | 100 | 380X275 | 40 | 550 | 430 | 100 | 10 | 318 | 230 |

| 40 | 433 | 430 |

| 80 | 780 | 530 | 150 | 80 | 610 | 530 |

| 120 | 684 | 630 |

| T38 | 200 | 940 | 265 | 127 | 450X280 | 80 | 687 | 530 | 125 | 80 | 550 | 530 |

| 120 | 792 | 630 | 175 | 120 | 653 | 630 |

| 150 | 962 | 630 | 175 | 180 | 866 | 630 |

| T46 | 353 | 1135 | 292 | 127 | 530X300 | 80 | 622 | 530 | 100 | 120 | 600 | 630 |

| 120 | 730 | 630 | 150 | 180 | 811 | 630 |

| 150 | 929 | 630 | 150 | 300 | 1235 | 630

|