350 Ton Hydraulic Horizontal Servo Motor Injection Molding Machine

CLAMING UNIT

-FEA designed double-toogle five-joint clamping machinery

-High rigidity mould platen with enlarged space between tie bar

-Platen with both T-slot and mould tapped

-Movable platen supported by the adjustable slide system which improves platen parallelism and life time of tie bar and mould

Applications:

Plastic Injection Molding Machine is for middle &big industrial parts, household appliances and other plastic products, material PC, PP, PE, Nylon, A.B.S. PVC etc., suitable plastic products weight 125g-213g, mold cavity can be:1 Cavity, 2 Cavities, 3 Cavities, 4 Cavities, 6 Cavities, 8 Cavities, 10 Cavities, 12 Cavities, 16 Cavities,

Description:

Injection molding machine is the type of fully automatic machine, being provided with high efficiency, high reliability, high speed, low noise, low power consumption and other advantages.

Machine main components adopt world famous brand, e.g.:

• PLC: TECHMATION CONTROLLER(Taiwan)

• AC Contactor: SIEMENS(Germany)

• Travel switch: SCHNEIDER(FRANCE),

• Transducer: NOVOTK (Germany)

• Proportional Valve: HNC(TAIWAN)

• Oil pump: VICKERS(USA)

• Directional Valve: VICKERS(USA)

• High-pressure pipe line: GOOD YEAR (USA)

Competitive advantages:

1. Designed by 3D software, structural strength are verified

2. T slot,threaded holes for mold installation

3. Hydraulic system with a self sealing oil suction filter and adopted the bypass filter device

4. The system robustness is strong, running stability

5. Timely and effective after-sales service

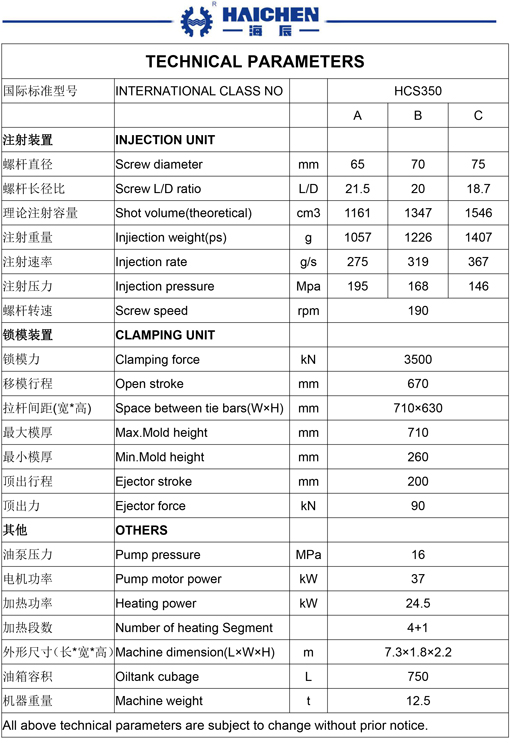

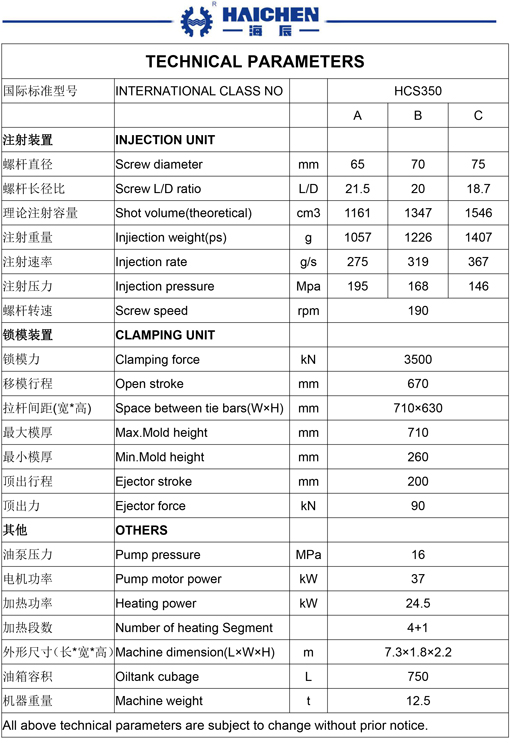

Specifications :