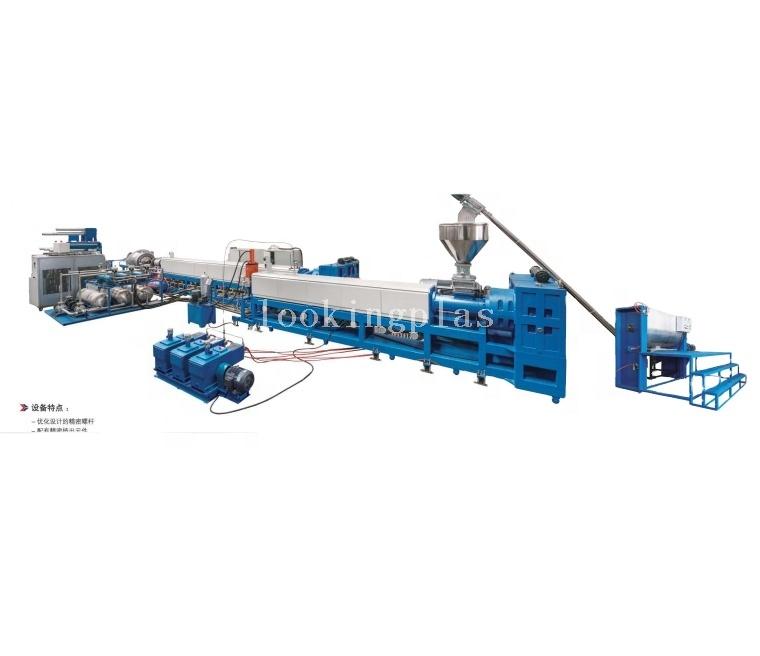

| Foam Polystyrene Sheet Extruder Main Techincal Parameters |

| Style No. Parameters | Unit | HLSJPS-130/170 | HLSJPS-120/150 | HLSJPS-100/130 | HLSJPS-90/120 | HLSJPS-80/100 | HLSJPS-70/90 |

| Capacity | kg/hr | 450-550 | 370-500 | 250-310 | 170-210 | 110-150 | 90-110 |

| Thickness | mm | 1.5-6 | 1.2-6 | 1.2-6 | 1.2-6 | 1.2-6 | 1.2-5 |

| Width | mm | 1000-2000 | 1000-2000 | 1000-2000 | 1000-2000 | 600-1300 | 500-1100 |

| Foaming Ratio | times | 11-30 | 11-30 | 11-30 | 11-30 | 11-30 | 11-30 |

| Linear Speed | m/min | 5-40 | 5-40 | 5-40 | 5-40 | 5-30 | 5-30 |

| Mounted Capacity | kw | 625 | 380 | 250 | 200 | 160 | 110 |

| Pressure of Cooling Water | mpa | ≥0.3 | ≥0.2 | ≥0.2 | ≥0.2 | ≥0.2 | ≥0.2 |

| Cooling Water | t/h | 20 | 18 | 13 | 11 | 8 | 6 |

| Compressed Air Pressure | mpa | 0.7-0.9 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Compressed Air Amount | CBM/min | 2 | 1.5 | 1.1 | 0.8 | 0.6 | 0.4 |

| Butane Injection Pressure | mpa | 1 | 1 | 1 | 1 | 1 | 1 |

| Weight | ton | 32 | 22 | 18 | 15 | 13 | 10 |

| Installation Size | m | 40*4.5*3 | 35*5*3 | 33*5*3 | 27*4*3 | 26*4*3 | 25*4*3 |

1.Production process

Expand Polystyrene Sheet Extruder is the sheet producing machine with 2 screws and by gas foaming method. It takes General Purpose Polystyrene (GPPS) as raw material, injects gas foaming agent during the producing process. And the Winder wraps up the sheet in rolls.

2.Product use

The sheet is for thermoforming purpose, and can be made into fast food containers, egg trays, disposable bowls etc. Since it has properties of heat and sound insulation, the sheet material is also widely used in architecture; such as decorative board, inner ceiling of car.