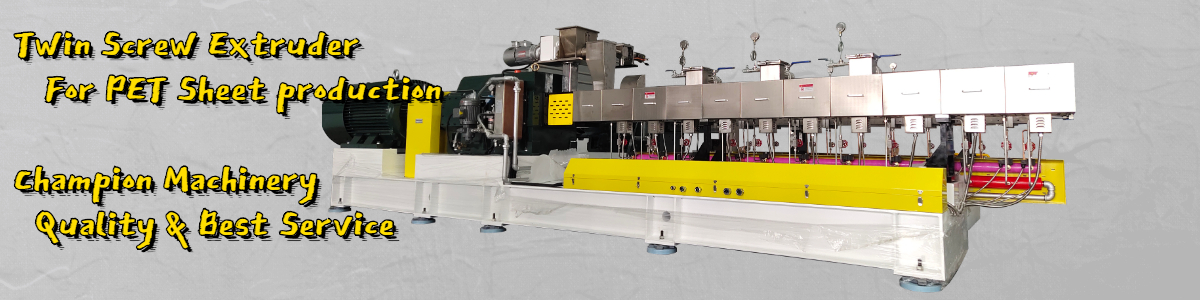

【PP/PE/ABS thick board extrusion line】Basic introduction:

1. Extruder type: single screw extruder / twin screw extruder

2. Calender structure: vertical type

3. Haul-off: 1# double haul-off unit & 2# single haul-off unit

4. Final board product: smooth surface, high flatness, no woven, high toughness

【PP/PE/ABS sheet/board extrusion line】Main technical specification:

| Model | CHD120 | CHD150 | CHD170 | CHD85 |

| Material | PP, PE, ABS |

| Width | 1200mm | 1500mm | 2000mm | 1500-2000mm |

| Thickness | 1-10mm | 3-30mm | 3-30mm | 3-30mm |

| Extruder | φ120/35 | φ150/35 | φ170/35 | φ85/44 |

| Capacity | 450kg/h | 650kg/h | 800kg/h | 700-800kg/h |

【PP/PE/ABS sheet/board extrusion line】Technological superiority:

1. Controlling system: adopt SIEMENS S7-1500 controlling system, equipped with SIEMENS frequency/servo for drive part. Through the Profinet network link, the controlling system is more credible, stable and efficient.

2. Operation: Through centralized control, you can browse all information of all parts in one screw, such as current, pressure, speed, temperature, vacuum pressure, etc.

【PP/PE/ABS sheet/board extrusion line】Running in customer's factory

【CHAMPION EXTRUSION】After service:

Complete after-sales service system, from the installation and debugging of machine to the production and manufacture of high-end products. We offer lifelong technical support.

On the basis of professional technique and digital network system, CHAMPION promises to offer technical solutions within 24 hours of any other questions of machine, and provide remote operation assistance if necessary, so as to solve your problems in the shortest time and resume normal production.

【Contact us】:

Contact: Miss. Sarah

E-mail: sarah@championshcn.com

Mobile/WeChat/LINE/Facebook: +86 13916267210

Web: www.championshcn.com