PE PIPE EXTRUSION PLANT

Designed to manufacture water pipes, gas pipes, high-voltage power protective pipes, sewage ducts, pipe for chemicals, pipe for telecommunications, pipe for irrigation, low temperature pipes and pipes for various industrial uses.

Faster extrusion, high output, more economical-these coincide with our principles in plant development which are aimed at designing for the clients. In view of the market requirements for human-based design and easy operation, we adopt intelligent automation and friendly interface system which makes the line run stable. Maintenance is also easy.

Feature and function:

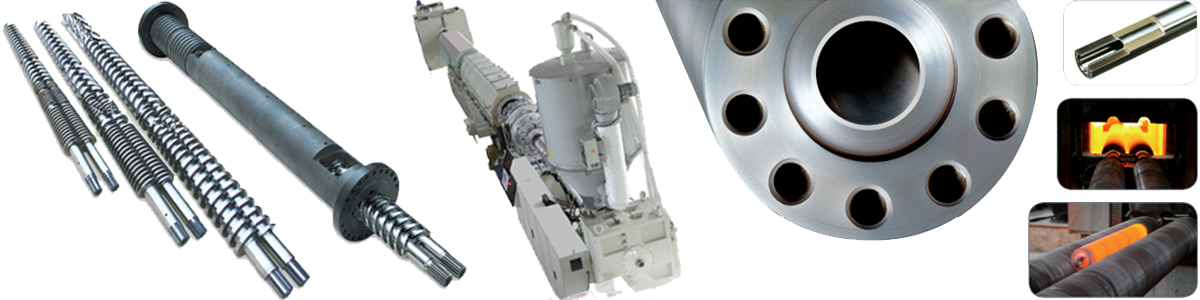

1.High performance extruder assembled with grooved feed bush and high efficiency mixing and low temperature extrusion screw.

2.Lattice basket dies are used for the extrusion of HDPE、LDPE、HMW-PE、PP、ABS and PS.

3.Special design for calibrator, water ring cooling system and water-membrane lubricant which allows thick wall pipe to be extruded at high speeds and stable dimensions.

4.Haul-off and extruder with coordinated control.

5.The easily configurable control panel in combination with the stepped automation concept ensures efficient working in all areas of pipe extrusion. PLC and PCC control system makes for easy operation.

Technical Specifications

MODEL | PIPE RANGE | EXTRUDER MODEL | CAPACITY (kg/h) |

PO63 | Φ16-Φ63 | HTE1-45 | 150 |

PO125 | Φ32-Φ125 | HTE1-60 | 300 |

PO250 | Φ63-Φ250 | HTE1-75 | 450 |

PO450 | Φ160-Φ450 | HTE1-90 | 600 |

PO630 | Φ315-Φ630 | HTE1-120 | 1000 |

PO800 | Φ355-Φ800 | HTE1-150 | 1200 |

Output dependent on material type and bulk density.

Subject to change without notice.