Description

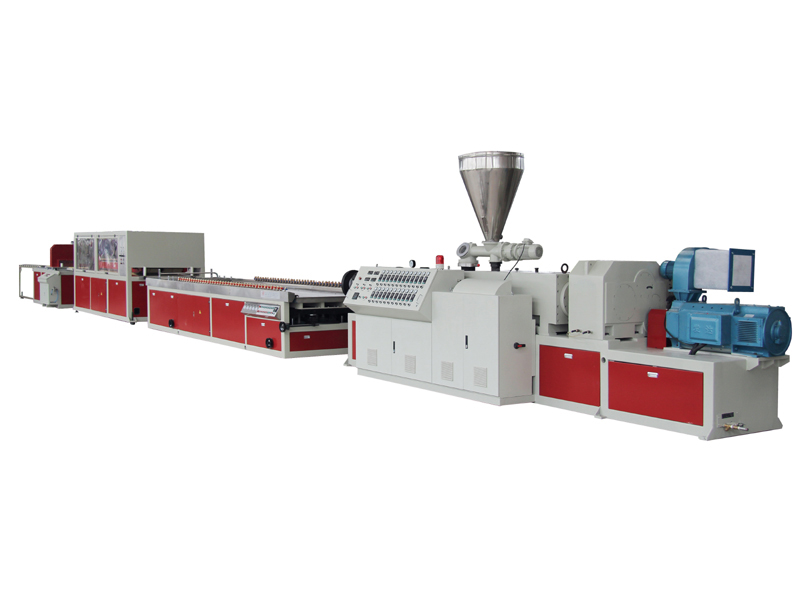

1. The extrusion line is mainly used to produce PVC ceiling panel. The width range is from 150mm to 600mm. It consists of conical twin screw extruder, vacuum calibration table, caterpillar haul off unit, rolling blade cutter and stacker.

2. The surface of PVC ceiling panel can be treated by double color printing & coated with glossy oil, or by thermal transfer printing machine, or by lamination, which can make marble, wooden design on surface of product .

3. PVC ceiling panel can be used in house and public decoration , office decoration, kitchen room , washing room decoration, it's environment-friendly raw materials and can be recycled, features non-pollution, long service time, heat insulation, anti-fire, easy to clean and maintanance, easy to change and recyclable.

Parameter

Production Line | SJZ53+YF300 | SJZ55+YF300 | SJZ65+YF400 | SJZ65+YF600 |

Power Supply | 380V, 50Hz, 3-phase or customized |

Extruder | SJZ53/125 | SJZ55/120 | SJZ65/132 | SJZ65/132 |

Screw Diameter | ¢53/125mm | ¢55/120mm | ¢65/132mm | ¢65/132mm |

Heating Power | 4 zones , total 15kw | 4 zones , total 14kw | 4 zones , total 19kw | 4 zones , total 19kw |

Main Motor Power | 22kw | 22kw | 37kw | 37kw |

Extruder Dimension | 3450*1500*2100mm | 3750*1500*2100mm | 4250*1500*2150mm | 4250*1500*2150mm |

Extruder Weight | 2000kg | 2500kg | 3500kg | 3500kg |

Output | 100-150kg/h | 100-150kg/h | 200-250kg/h | 200-250kg/h |

Max Product Width | 300mm | 300mm | 400mm | 600mm |

Technical Process

Finished Products

Machine Delivery