Description

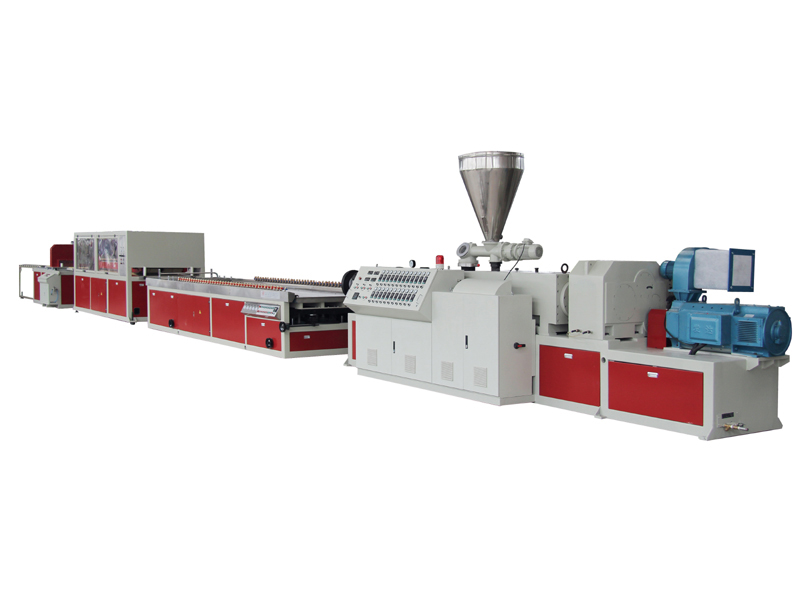

1. This production line is mainly used to produce PVC wall panel/board. It consists of conical twin screw extruder, vacuum calibration table, caterpillar haul off unit, rolling blade cutter and stacker.

2. The width range of PVC wall panel normally from 150mm to 600mm.

3. The surface of PVC wall plate can be treated by double color roller printing or coated with UV lacquer, by hot stamping printing, or by lamination, which can make marble, wooden design on surface of product.

4. Advantage of PVC wall panel : clean and easy to install, low production cost, waterproof, soundproof, fire resistant, ECO-friendly.

5. Advantage of PVC wall panel ; energy saving (15% down), high standard (Bimetallic & PLC Intelligence), Excellent screw design (suitable for high percent CaCo3 and wood powder)

Technical Parameter

Production Line | SJZ65+YF400 | SJZ65+YF600 |

Power Supply | 380V, 50Hz, 3-phase or customized |

Extruder | SJZ65/132 |

Screw Diameter | ¢65/132mm |

Heating Power | 4 zones , total 19kw , 50-300°C |

Main Motor Power | 37kw |

Extruder Dimension | 4250*1500*2150mm |

Extruder Weight | 3500kg |

Output | 200-250kg/h, <5m/min |

Max Product Width | 400mm | 600mm |

Detailed Images

Finished Products

Container Loading