Description

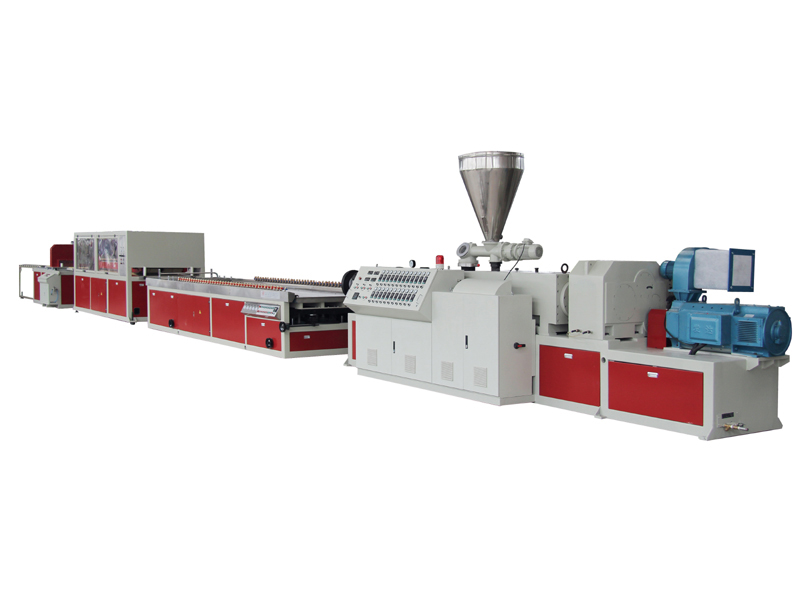

1. PVC Pipe Extrusion Line, including conical twin screw extruder, pipe die head, vacuum calibrating tank, water spraying tank, haul off machine, cutting machine, and stacker etc.

2. We offer screws of updated structures for raw materiel with big or smalI proportion of filling materials such as calcium carbonate. Equipped with different mouIds and downstream equipment, the Iine can produces UPVC, C-PVC, PVC-M, PVC-0 pipes, composite pipes with foamed middle Iayer, composite foamed pipes with inner spirals.

3. PVC pipe making machine is mainly used to produce agricultural water supply/drainage pipes, architectural water supply/drainage pipes, cable laying pipes etc.

4. Our machine adopts advanced design concept to ensure the efficient extrusion of PVC powder, combined with the unique concept of plasticization screw design to ensure uniformity of plastic extrusion, high capacity production.

Technical Parameter

Production Line | SJZ65/132+GF160 | SJZ80/156+GF400 |

Power Supply | 380V, 50Hz, 3-phase or customized |

Extruder | SJZ65/132 | SJZ80/156 |

Screw Diameter | ¢65/132mm | ¢80/156mm |

Heating Power | 4 zones , total 19kw | 4 zones , total 36kw |

Main Motor Power | 37kw | 55kw |

Extruder Dimension | 4250*1500*2100mm | 4750*1500*2100mm |

Extruder Weight | 3500kg | 5000kg |

Output | 200-250kg/h | 350-380kg/h |

Diameter Range | ø63-ø160mm | Ø100-ø315mm |

Product Flow

Screw Loader for Mixer → Mixer unit → Screw Loader for Extruder → Conical Twin Screw Extruder → Mould → Vacuum Calibration Tank → Four claws Haul-off → Planetary Saw Cutter → Belling machine/ Tripping Table → Final Product Inspecting &Packing

Detailed Parts

Finished Products

Container Loading