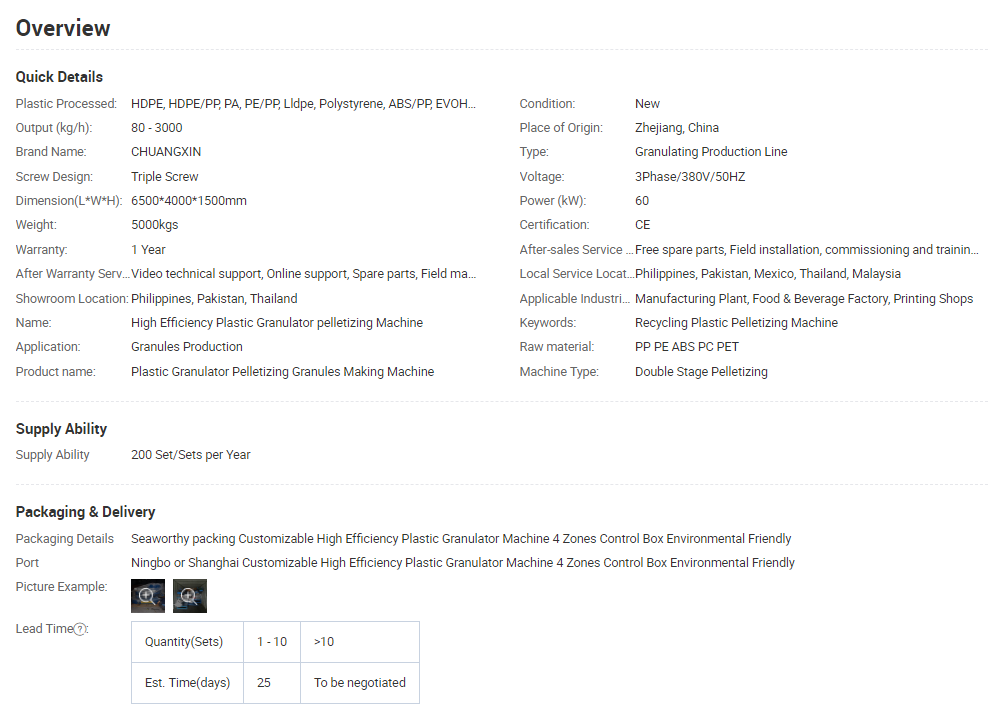

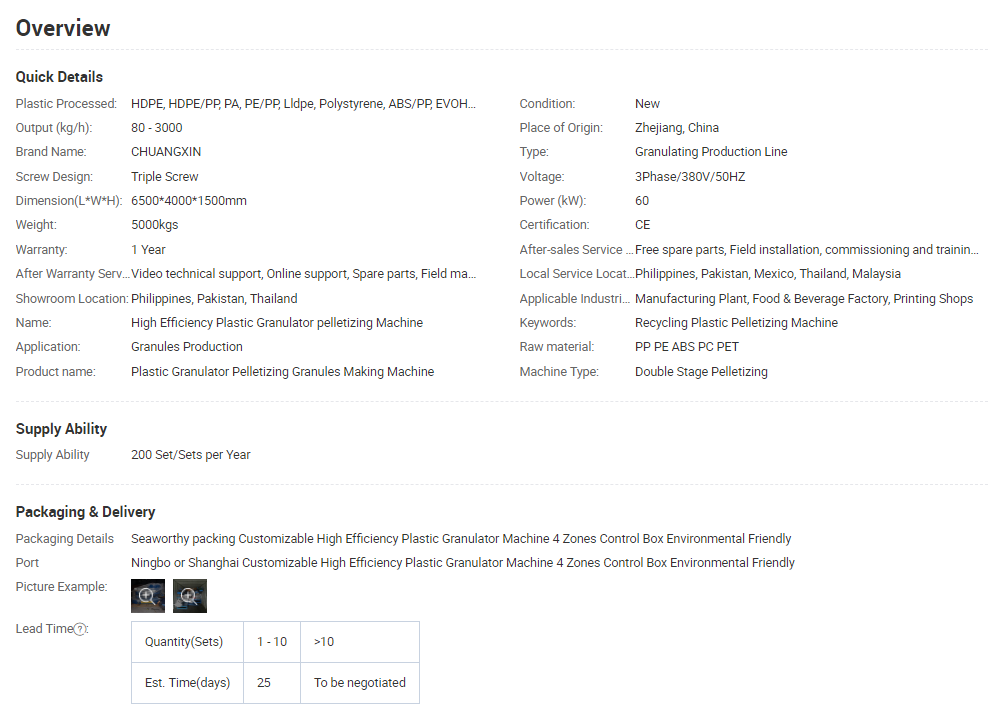

High Efficiency Plastic Granulator Machine 4 Zones Control Box Environmental Friendly

General description:

1. Process material: PE/PP/ABS/PC/PS and so on(Finished picture)

2. Extruder Model: CX-120-100

3. Capacity:100kg/hour.

4. Pelletizing ways : Water strand Granulation production line

5. Power supply: 3Phase/380V/50HZ

6. The machine color use orange yellow and blue.Customer can choice color you want.

I.Flow chart of Granulating line:

The process flow of the pelletizing line as following:

Hopper→ Gear box→Main Screw→ Driving system→ CX-120 Main Heating system→ Gear box→Auxiliary Screw→ Driving system→ CX-100 Auxiliary Heating system→Control system→ Filter System→ Cooling system→ Pelletization system

II. Specification for each equipment

1.Stainless Steel Hopper

(can be produced as special requirement)

The force feeding hopper for customer option.

2. Gear Box

1. Material: 173 country standard hardened gear box (main extruder)

146 country standard hardened gear box (auxiliary extruder)

2. Features:

The material of gear is the high strength alloy steel, it is manufactured by carburizing, quenching (and other heat treatment), grinding process at last. The gear is in high precision (6 grade) and high hardness (reached HRC54-62). Besides, it features low noise when operating.

It contains high bearing ability thrust, which is performed reliable and can with stand larger axial thrust.

3. Screw

Main extruder:

Screw diameter: φ120mm,screw length 2.2m(rotate speed 60-80 r/m)

Screw L/D: 18:1 screw material: 38Alloy Steel

Auxiliary extruder:

Screw diameter: φ100mm,screw length 1.2m(rotate speed 60-80 r/m)

Screw L/D: 11:1 screw material: 38Alloy Steel

Screw features:

38CrMoAIA, high temperature nitride

Tempering hardness: HB230-250

Nitride hardness: HV850-950

Nitride depth: 0.5-0.7mm

Brittleness:less than 2

4. Driving System

Main extruder:

Driving system adopts to motor of 40kw from Nanjing,

Frequency transformer is star triangle start.

Auxiliary extruder:

Driving system adopts to motor of 10kw from Nanjing,

Frequency transformer is 6kw from Shanghai Maifu (nationwide warranty).

5. CX-120 Heating System

Main extruder: Ceramics heating system, 4 zones.

Heating power: 12kw.

Auxiliary extruder: Ceramics heating system,3 zones.

Heating power:3-6kw.

Ceramic Heater Band

Performance advantages: ceramic heater is installed spirit fast, good insulation, high temperature resistant, heat transfer, production is not affected by the size of the type and specification limits, etc.Product structure: the ceramic heater is made with stainless steel skin shell, have higher degree of insulating refractory ceramic wear resistance wire, then mechanically ground type, connect the power and can be used.

6. Control System

All the Electrical acceessories adopt to the brand of CHINT.

7. Filter System

Hydraulic screen changer with hydraulic pump, screen diameter: 100mm (Auxiliary extruder)

Extruding lines: 12~18pieces (or as special requirement)

Extruding width: 3~4mm

Heating machine: stainless steel heating machine

Heating power: 2kw

1. Changing screen without stopping: 1.5KW

2. Time of changing screen<2 s

3. System pressure: 16 mpa

4. Changing material: 40C

For more information, please add my whatapp/viber/mobile/wechat/qq:+8615325773210

Our Service and Technical Support:

1.Easy fault parts supplying.

2.Online Error solution

3.Installation with commissioning

4.Trainning for the operator

5.Machine software upgraded

6.Manual for products.

7.Error maintenace.

8.The others problems that buyers will be concern

There will be an operation training for operator:

(1) Training for right operation;

(2) Training for common sense of daily maintenance;

(3) Introducing after-sale services and training for solutions;

(4) Introducing after-sale services and notify the contact way; Accessories supply guarantee: We supply free accessories within one year warranty period. We will charge you for accessories supply when the warranty is overdue;