Horizontal Bale Breaker with Patented

Bale braeker is applied to PET bottle recycling industry to break up PET bottle bales. Cutting the wires of the PET bottle bale manually in the first step, then PET bottle bales will be transported to bale breaker shafts via belt conveyor or chain conveyor. PET bottle bales become loose bottles under the function of powerful rolling paddles.

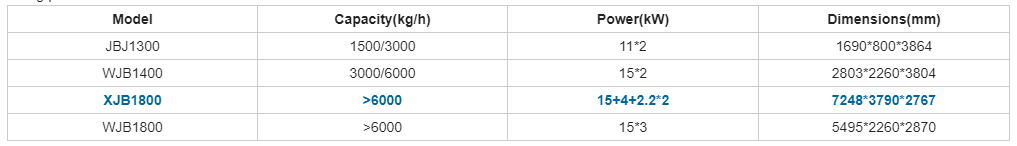

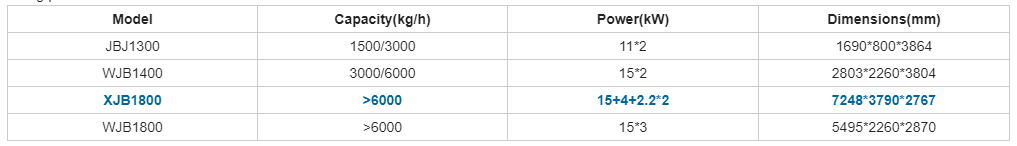

Rrmarks: Capacity will be affected by PET baler packing density

Standard Process Flowchart for Your Reference (Process as per layout based on customer's factory and rPET flakes applications demand)

De-baling------Metal Separation------ Label Scrapping------- Label Separation-------- Presorting------Bottle Pre-washing ------Automatic Sorting/Manual Sorting -----Wet Grinding-------Drying-------Hot Flotation-------Friction-------Continuous Rinsing-----Drying--------Dust Removal------Packing

De-baling Section introduction

De-baling unit adopts weighing-connected feeding device by high automation technology and break up bottle bales and remove mixed metal. The special knife structure can avoid any unexpected mechanical clogging.

More details, you can also send enquiry to our sales mail: sales@bo-re-tech.com