Application area

HDPE series plastic pipe production line can be widely used in the production of agricultural water supply/drainage pipe, municipal engineering water supply pipe, gas pipe, silicon core pipe, wire and cable casing, double wall bellows and other polyolefin pipe.

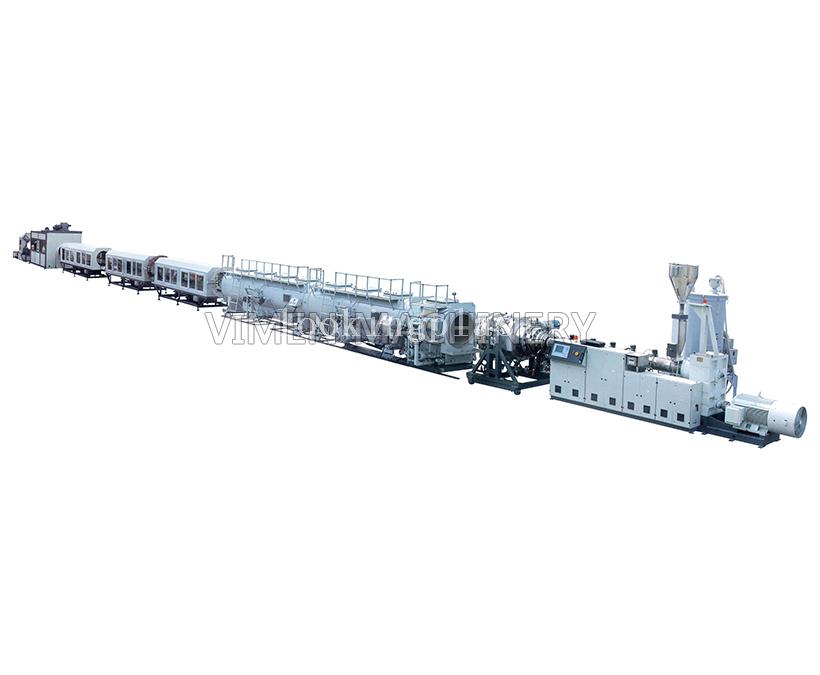

Production line

HDPE pipe production line equipment mainly by: Single screw extruder, Die head, Vacuum calibration tank, Spray cooling tank, Haul-off, Chipless cutter, Stacker(Winder), Hopper dryer, Vacuum feeder, gravimetric control system.

Value advantage

1.Single screw and high efficiency extruder is divided into two: high efficiency of 33:1 aspect ratio of the screw and super high efficiency of 38:1 aspect ratio of the screw , barrel adopts the unique way of blanking, effectively improve the extrusion production, advanced protective screen type cuts screw structure can improve the plasticizing effect of material and the quality of the products, with advanced meters weight measuring system, compared with the previous old models, reduce the energy consumption is as high as 30%;

2. The mold adopts spiral structure, equipped with high-speed sizing sleeve, and the molding effect is good.

3. True empty box, spray box adopts advanced pipe wiring design and adjustable nozzle, cooling effect is better.Automatic control of water temperature and water level in the box, double volume filtration, gas-water separation device, centralized inlet and drainage design.

4. According to the different pipe diameter of the products, the tractor is equipped with two claws, three claws, four claws, six claws, eight claws, ten claws, twelve claws and other traction methods. The high quality rubber block is used for stable traction.

5. The cutting machine has two ways for customers to choose: blade without chipless cutting and saw blade sawing cutting.

Technical parameter

33:1 Series extrusion production line:

Model | Pipe Diameter (mm) | Extruder | Motor Power (kw) | Max Capacity (kg/h) |

VM-630 I | Φ 315-630 | SJ 120/33 | 250 | 800-900 |

VM-800 I | Φ 500-800 | SJ 150/33 | 355 | 850-1050 |

VM-1000 I | Φ 630-1000 | SJ 150/33 | 400 | 1000-1200 |

38:1 Series extrusion production line:

Model | Pipe Diameter (mm) | Extruder | Motor Power (kw) | Max Capacity (kg/h) |

VM-630 II | Φ 315-630 | VMD 90/38 | 280 | 900-1000 |

VM-800 II | Φ 500-800 | VMD 120/38 | 355 | 1200-1400 |

VM-1200 II | Φ 710-1200 | VMD 75/38+90/38 | 160+250 | 1350-1450 |

VM-1600 II | Φ 1000-1600 | VMD 90/38+90/38 | 280+280 | 1600-1800 |