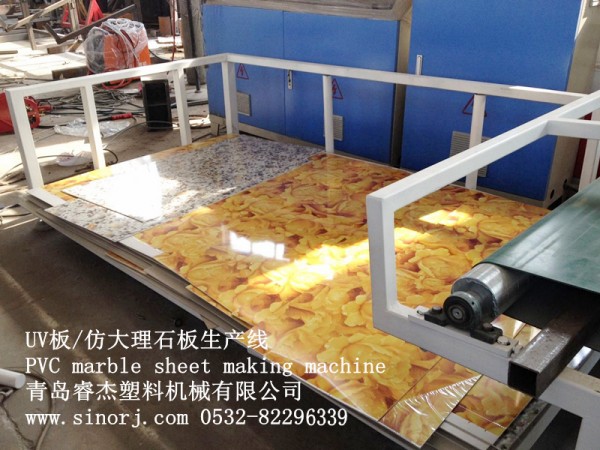

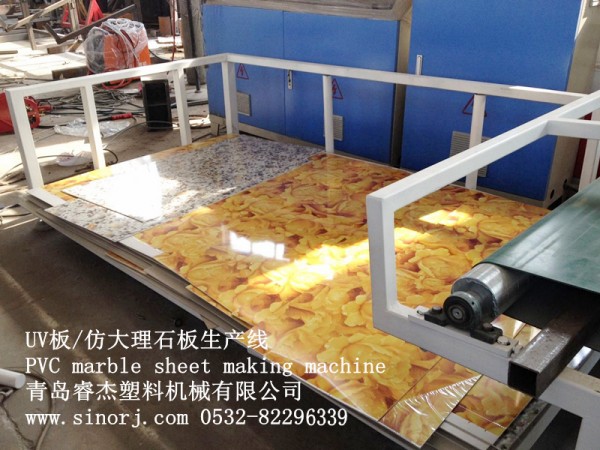

PVC Artifical Marble Plate Making Machine

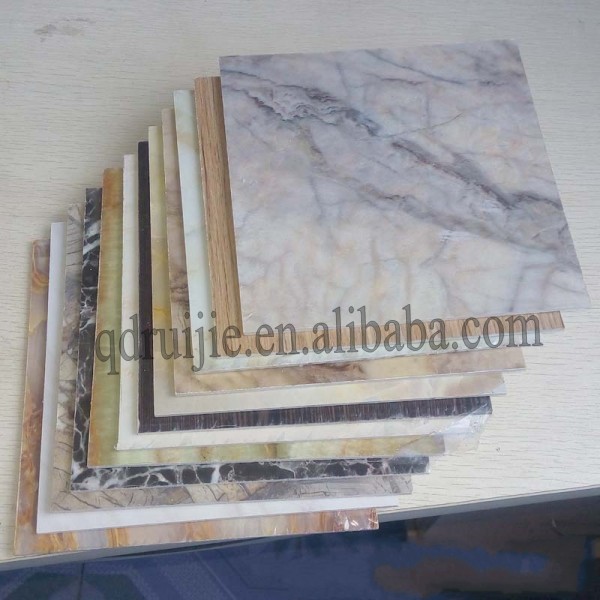

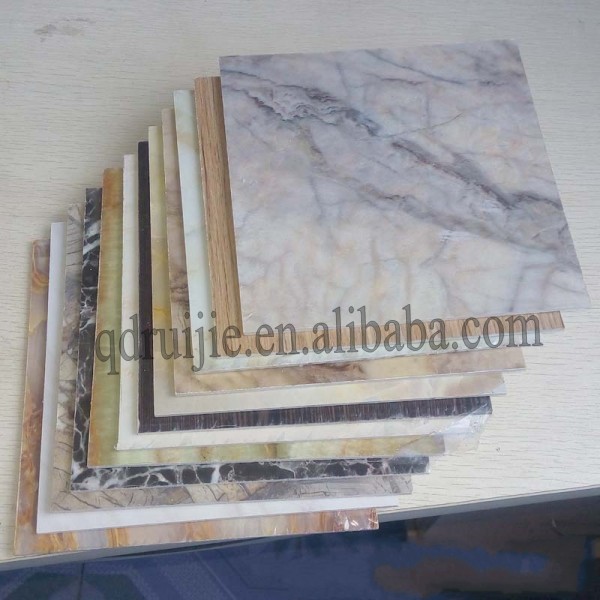

PVC Artificial Marble Plate

Products width: 1220mm

Products Thickness: 2-6mm

Advantages of PVC Artificial Marble Plate

1, Environment friendly

2, Recycled available

3, Water proof

4, Anti-corrosion

5, Deformation hard .

Flow chart of producing

Crusher (crushing the edge of board trimmed) → Miller (milling the

scraps into powder → Mixer (mixing the main materials and additives) → SJSZ 80- 156 Twin Conical Screws Extruder → Mould → Lamination

unit → Threecalender unit → Cooling Bracket → Hualoff Machine →

Edge Cutting → Cutter → Stacker .

Configuration

PVC raw materials Loading and Mixing system |

1. Spiral Loader or Vacuum auto Loader | 1 set |

2. High speed Heating Cooling Mixer unit | 1 set |

PVC marble sheet Extrusion Line |

1. Spring Loader or Spiral Loader | 1 set |

2. SJZ80/156 Conical double screw Extruder | 1 set |

3. Mold/Die head Set | 1 set |

4. Three-roller Calander with Marble film unit | 1 set |

5. Temperature controller of three rollers | 1 set |

6. Cooling frame with side cutting | 1 set |

7. Haul off unit | 1 set |

8. Cutting unit | 1 set |

9. Stacker | 1 set |

Sheet/Plate Recycling machines |

1. Sheet Crusher/Grinder | 1 set |

2. PVC Pulverizer/Miller | 1 set |