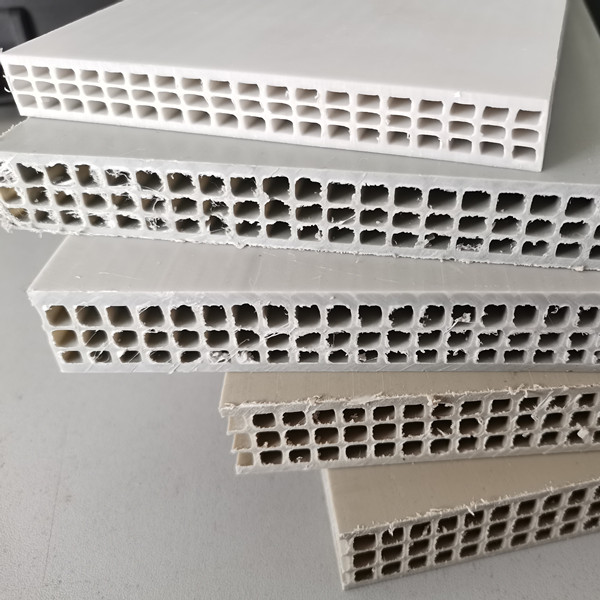

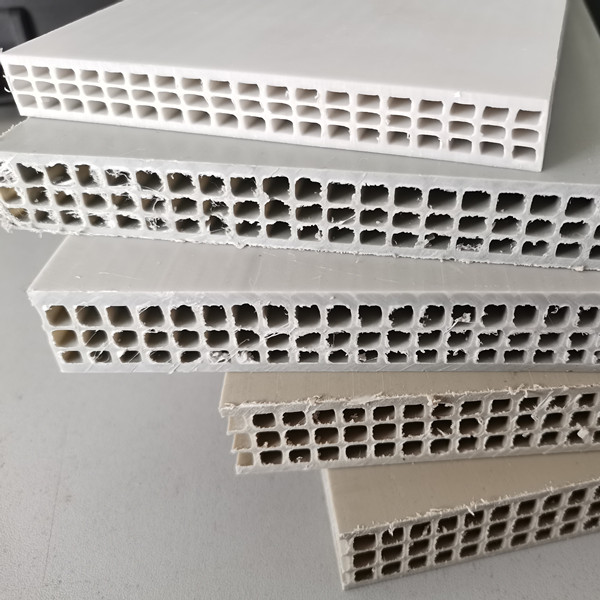

Plastic Extrusion Machine/Plastic PP Hollow Building Formwork Template Production Line Extrusion Machine/3 Layers PP Plastic Hollow Building Formwork Construction Template Production Line.

The PP building templates extrusion production line is successfully developed by our company to absorb and digest foreign advanced extrusion technology and independent innovation. The plate thickness range can be made to 8-18mm, and the plate width can be customized according to customer's requirements of 600mm-915mm-1220mm. Its production surface is smooth and clean, Small size error, with nail, planing, corrosion resistance, flame retardant and many other advantages.

PP new hollow building formwork production line This unit has a single screw extruder consisting of hydraulic screen changer, mold, primary traction machine, annealing furnace, cooling section, secondary traction machine, cross cutting machine and conveyor. In the industry, the initial O-shaped hollow structure was changed to the m-shaped, V-shaped, N-shaped, and well-shaped type, and finally changed to a grid type. The grid-shaped structure is accepted by the market in terms of material usage and structural properties. The surface of the produced product is smooth and has small dimensional error, and has many advantages such as nailing, planing, corrosion resistance and flame retardancy.

Compared with traditional building templates, PP building templates have the following advantages:

1. Good water resistance. Even if it is completely immersed in water for many days, it will not be deformed by moisture. It is resistant to acid and alkali, corrosion-resistant, and will not rot and rust. It is especially suitable for use in wet environments such as basement engineering, road railways and bridge piers.

2. It is not compatible with cement, it is easy to demould after construction, and the page will not be deformed by cement adhesion.

3, the plastic template surface is smooth, smooth, no need to apply mold release agent, reducing cleaning and maintenance costs. The surface of the building with which it is constructed is smooth and flat, and no secondary modification is necessary.

4. Light weight, high efficiency, convenient support, low labor intensity and high construction efficiency.

5, the support strength is high, not easy to deform, but impact, and wear.

6, low cost. Long service life, the number of turnovers can reach more than 100 times. The used scrap plates and scraps can be recycled and reused, saving costs and reducing pollution. The combined use cost can save more than 30% compared with traditional wood formwork.

7, long life, repeated use times. The final damaged plastic formwork can still be crushed again, re-processed into a new formwork, saving resources and meeting the requirements of “green industry”.

8, good insulation, is conducive to shorten the construction period.

9. Various methods can be used for the home wood method, and welding can also be carried out, so the secondary processing can be flexibly performed at the construction site.

10, plastic template can be processed, can be planed, sawable, nailable, can be used together with wood formwork

11. The process is saved and the construction efficiency is improved. The two surfaces (smooth surface or tread surface) of the PP hollow plastic building template have different use effects. If the surface of the carcass is smooth and smooth after the concrete is poured by using the smooth surface, the surface of the carcass is clean and smooth, and the requirements of the decorative surface and the decorative water are not required. The second time is used, the material is saved, the cleaning and maintenance costs are reduced, and the quality of the concrete after molding is reduced. Stable and save time. If a tread is used, it is advantageous to combine with the plaster layer. In particular, the first two piers are achieved by using a tread surface.