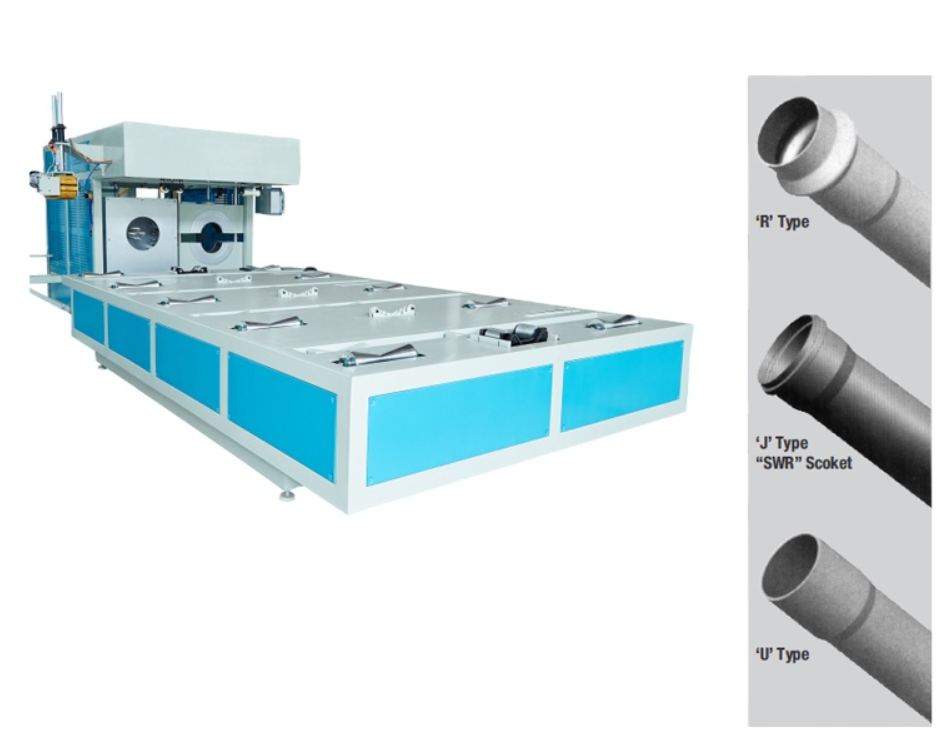

PVC Pipe Socketing Machine Application

PVC Pipe Socketing Machine is a semi-automatic machine, which can be used as a single machine.

And it is a after-treatment of PVC pipe making machine

The machine USES infrared heating;

The forming methods are all shaped by expanding pipe head, and the forming size of pipe mouth is accurate. The control panel of

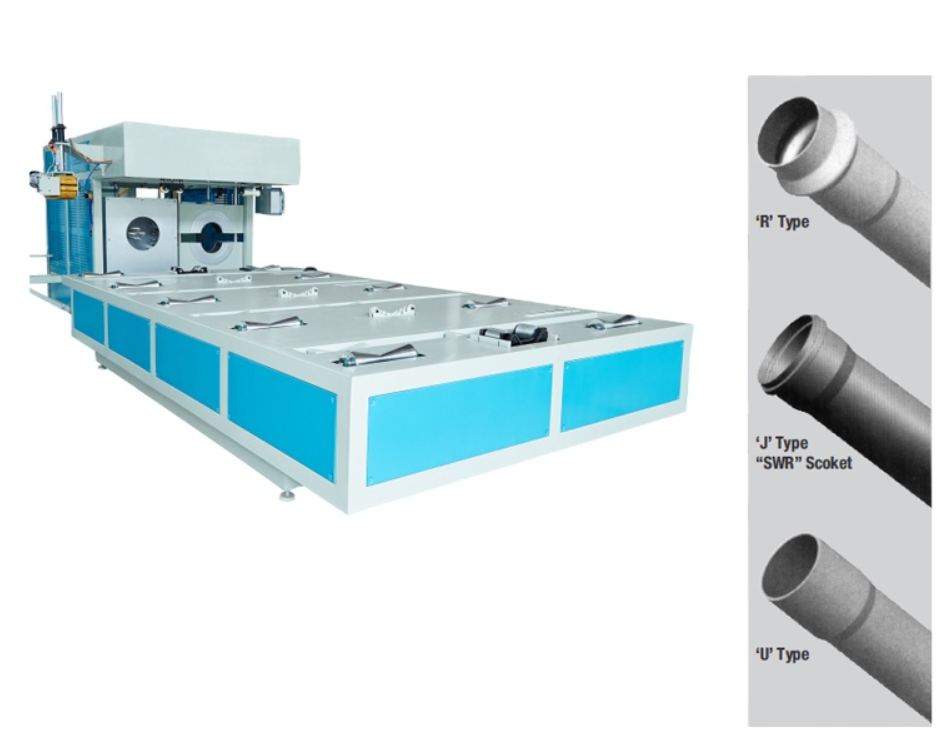

this machine is equipped with a switch of expanding solvent socket (straight port) and expanding elastic sealing ring socket (R

port). Mainly electrical control components are imported components, the system performance is stable and reliable.

Suitable for the R type ,U type and Rectangle plastic pipe.

PVC Pipe Socketing Machine Main Features

1)The equipment has high degree of automation and stable and reliable performance.

2)The air duct material is made of stainless steel, which can ensure no high temperature iron oxide falling off in the process of drying the pipe and cause the pipe head scar spot.

3)The frame is made of cold-drawn rectangular steel pipe welded with high rigidity and reasonable structure.

4)Cooling by air pressure cooling, no damage to the mold and no pollution.

Functional specification

1. Pneumatic propulsion heating furnace, heating furnace can be fine-tuned high and low and feed limit, electric heat pipe semi-open indirect heating, rotating speed by the manufacturer design (timing positive and negative).

2. The center of the machine is adjusted as a point-moving electric chain drive lifting, with a high center of about 1 meter.

3. The hosting rack is 4.8m, and the fitting pipe length is 4-6m.